Method and device of alignment detection and adjustment of conterminous rotation shafts

A technology of rotation axis and image detection, applied in measuring devices, optical devices, measuring/indicating equipment, etc., can solve the problems of inconvenient operation, required angle, expensive price, etc., and achieve the effect of simple and humanized operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The content of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so as to facilitate understanding of the content of the present invention.

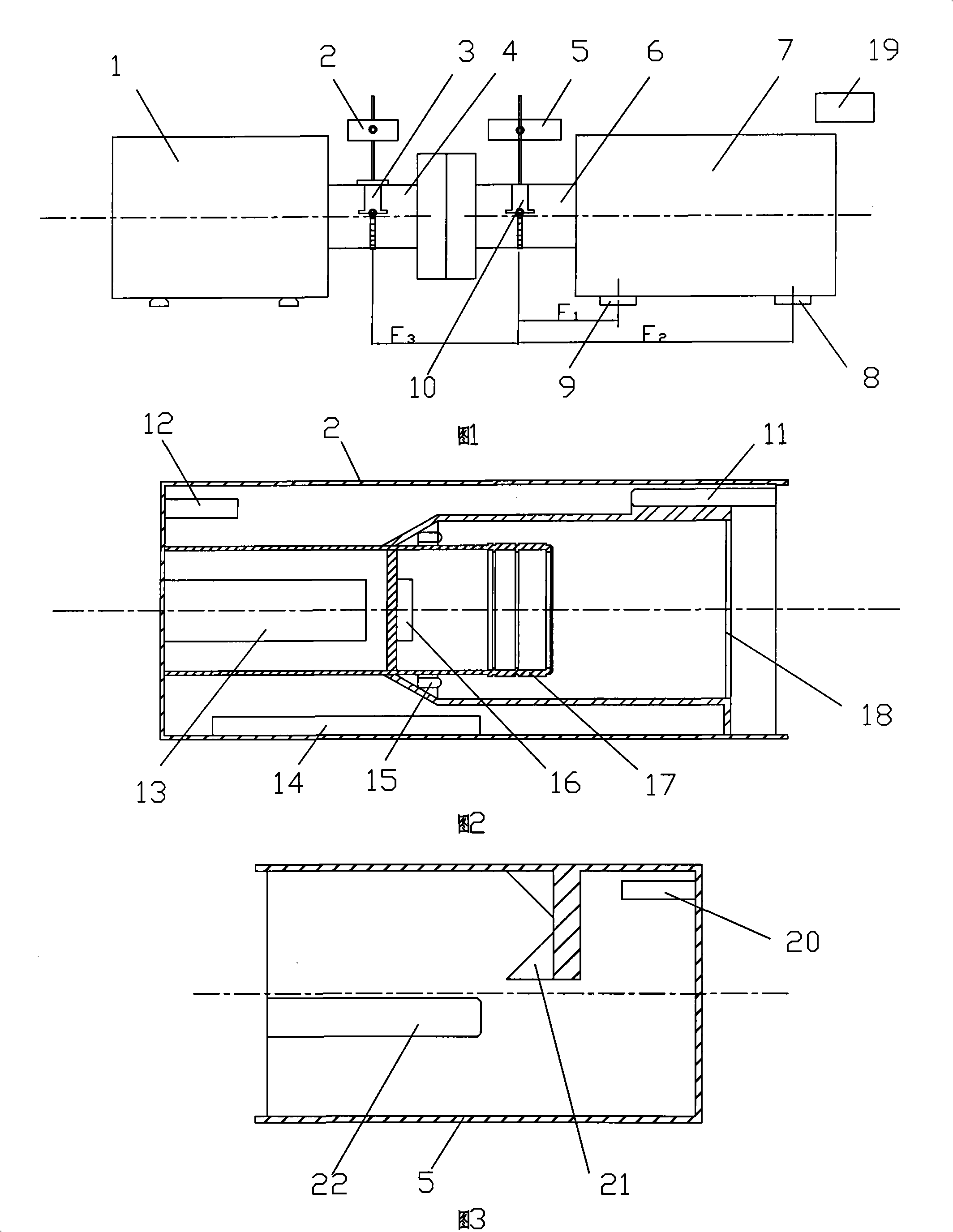

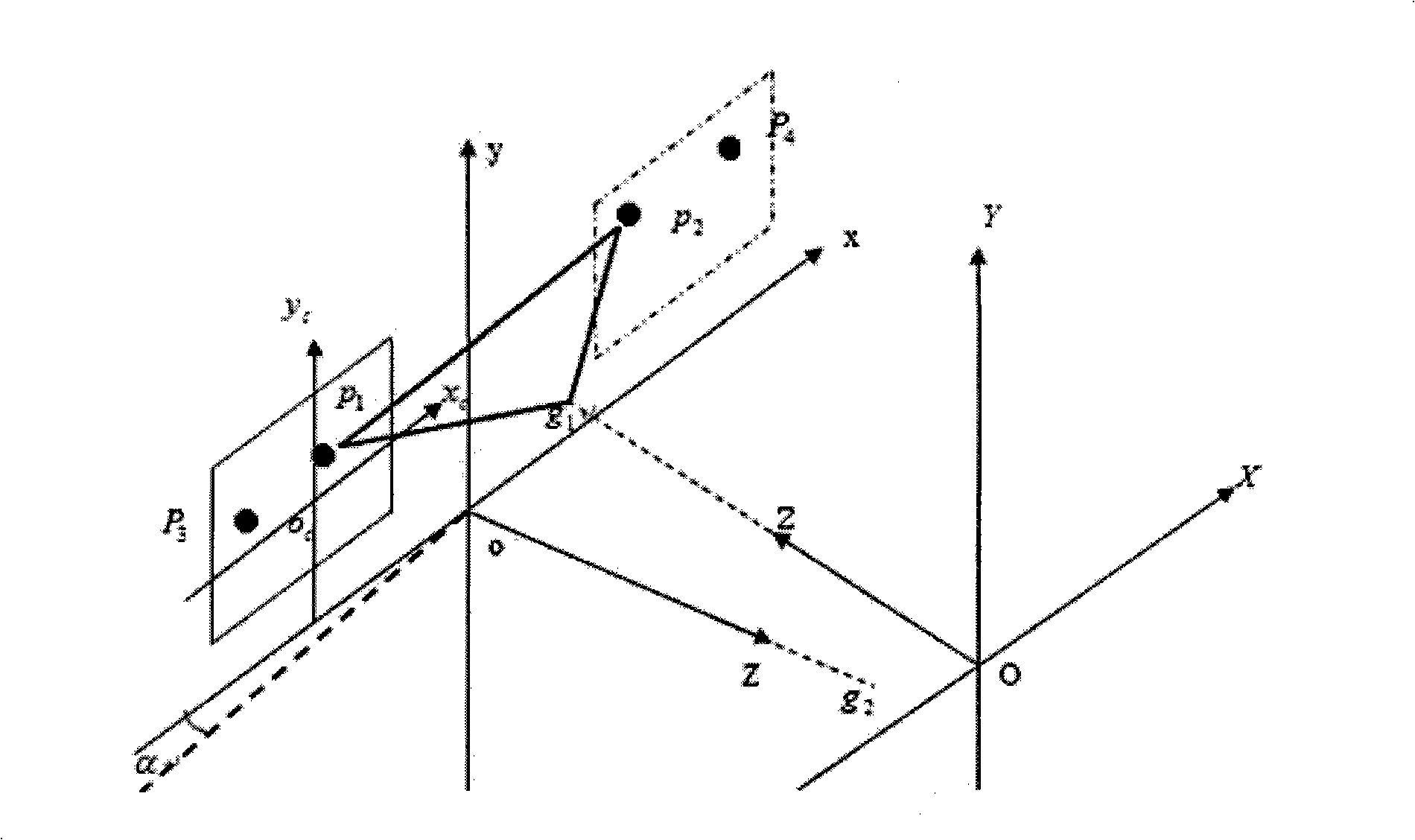

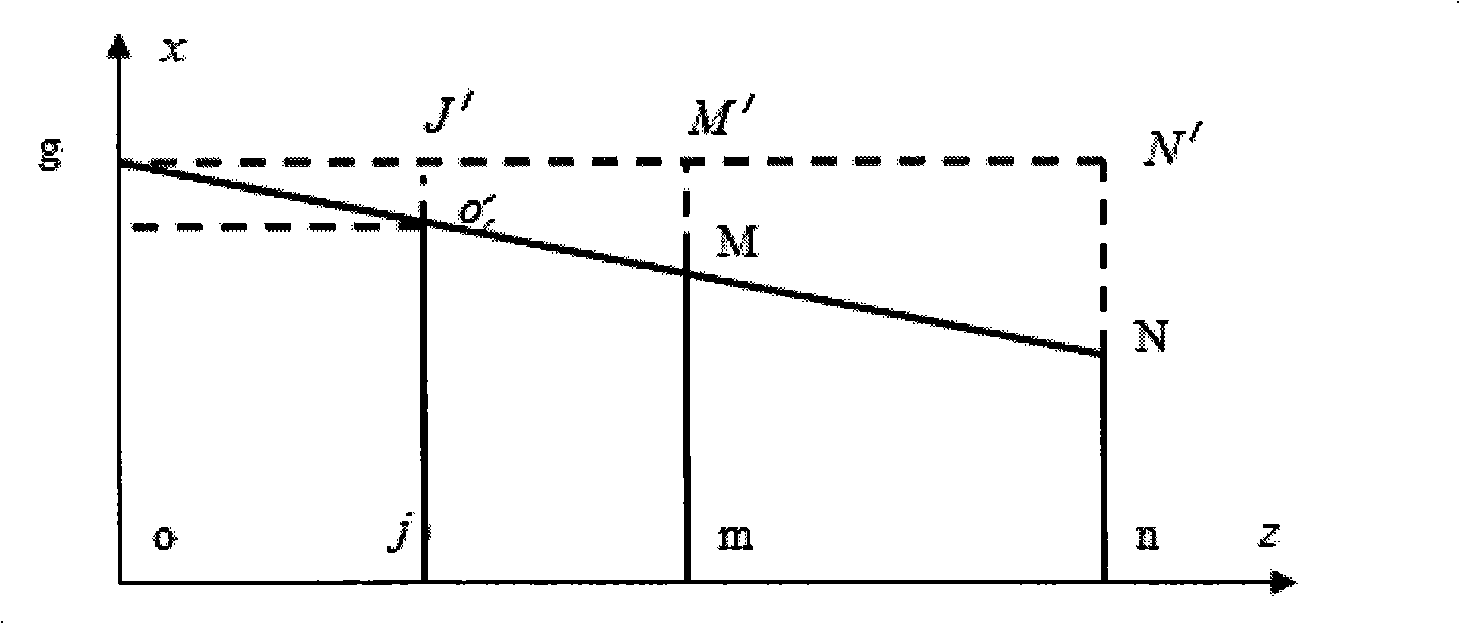

[0026] Referring to FIG. 1 , FIG. 2 and FIG. 3 , taking the detection of the rotation center of the rotating shaft of a rotating mechanical device as an example, the mechanical device where the detected rotating shaft is located is divided into a slave device and an active device. It mainly includes the following contents:

[0027] The image detection unit 2 is installed on the active rotation shaft 4 of the active device 1 through the first mechanical installation fixture 3, that is, the deck, the fastening chain and the vertical fixed bracket. The image detection unit 2 is equipped with the first laser emitter 11 and The first inclinometer 12; a group of reflective prisms 21, the integrated laser emission and reflection unit 5 of the second laser emitter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com