Traction power supply equipment based on PWM rectifier and control method

A traction power supply and control method technology, applied in the direction of output power conversion device, conversion equipment that can be converted to DC without intermediate conversion, electrical components, etc., can solve the problem of large harmonic pollution of AC power grid, uncontrollable DC voltage, and traction problems. High power and other issues, to achieve significant energy saving effect, fast protection speed, fast dynamic response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The traction power supply device in this embodiment has a DC voltage of 750V and a power of 500kW.

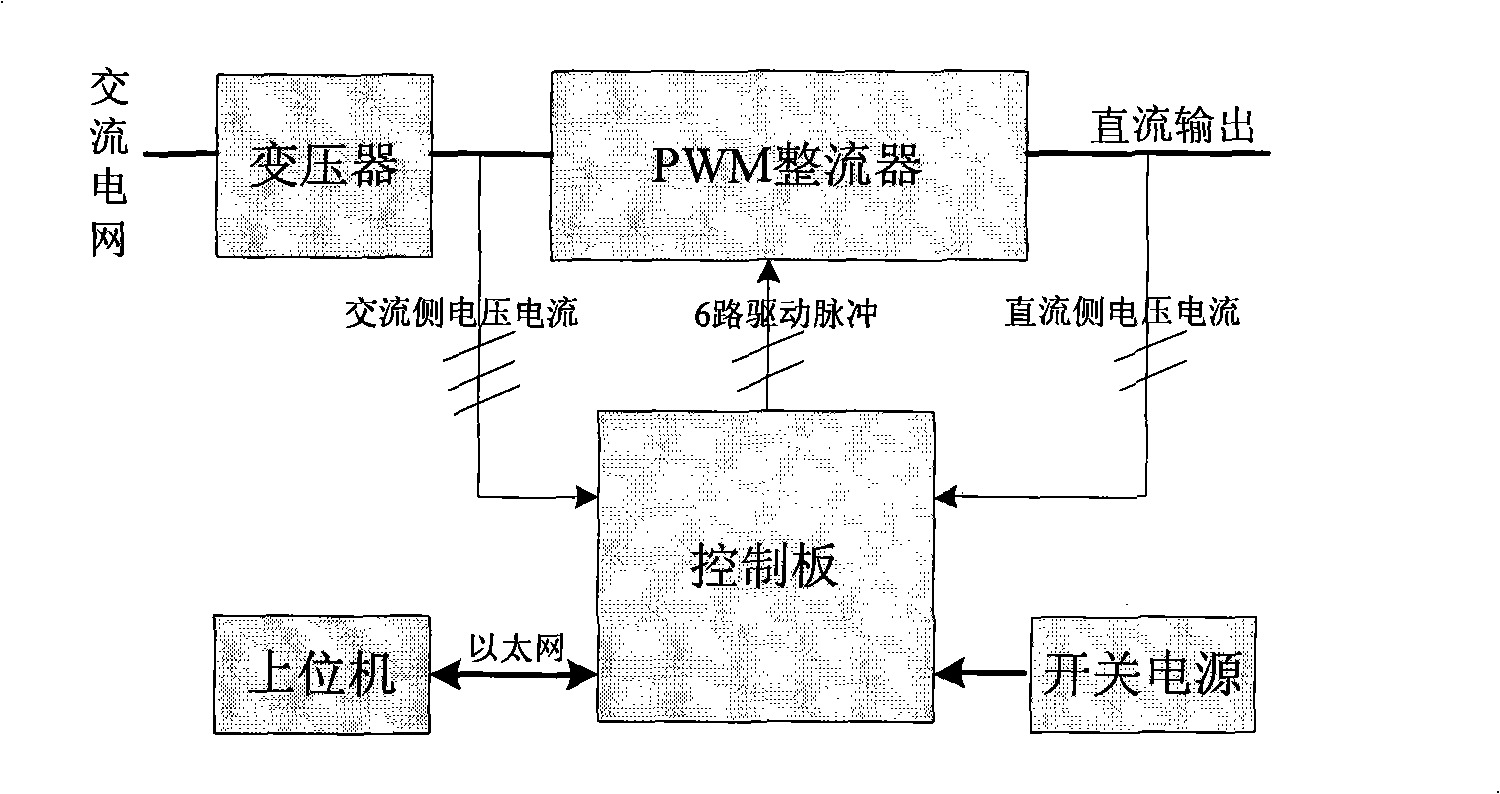

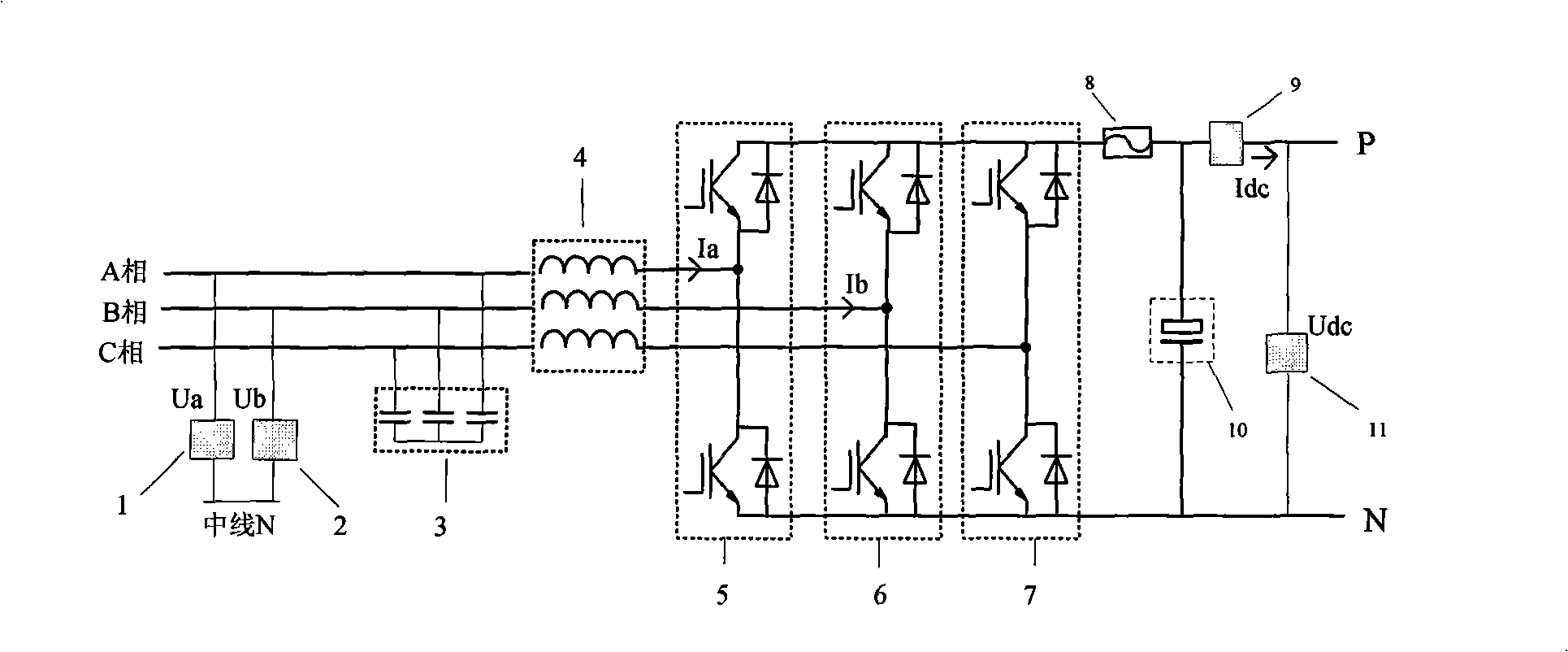

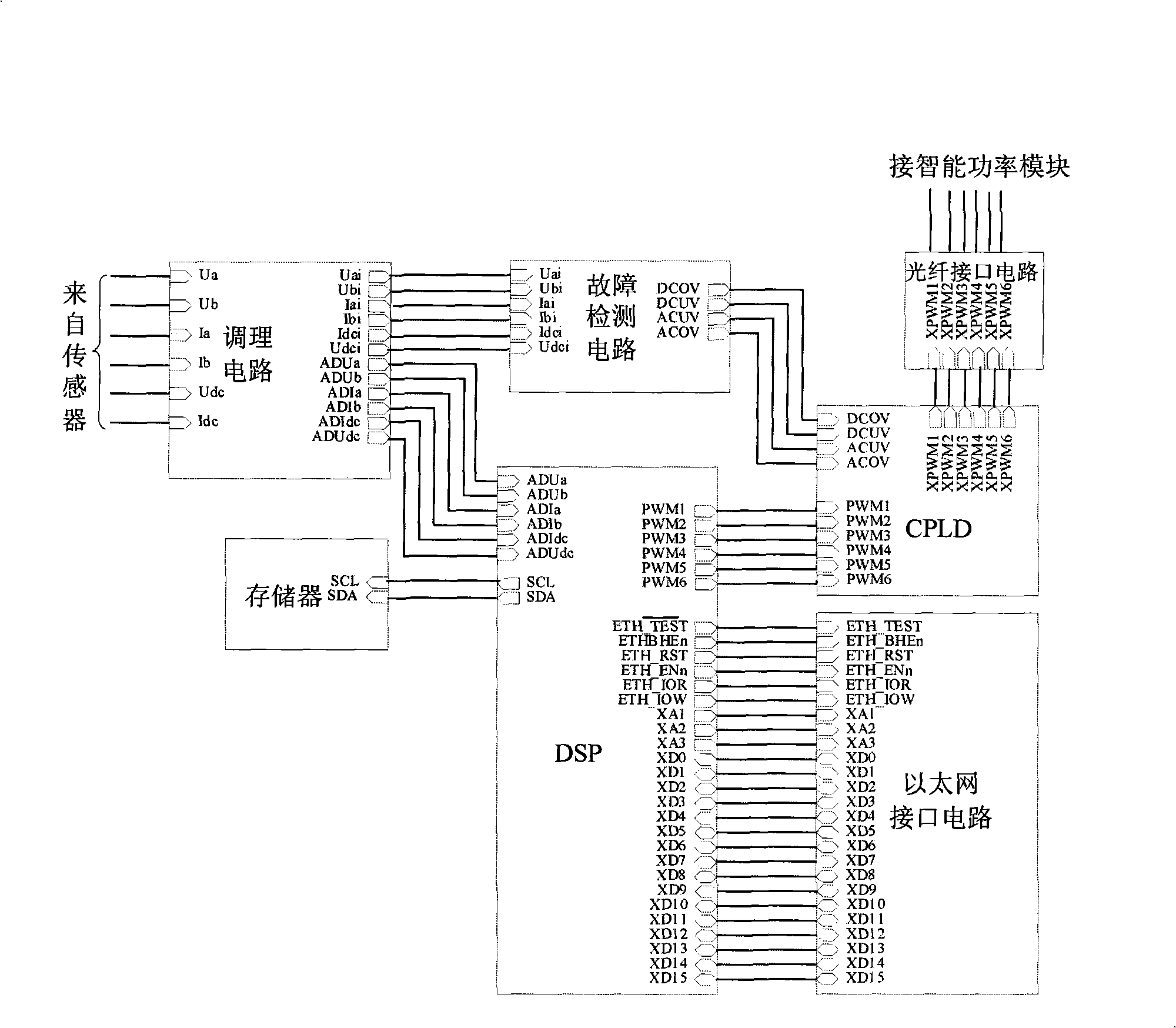

[0030] The traction power supply device of this embodiment, such as figure 1 As shown, the device is composed of five parts: transformer, PWM rectifier, control board, upper computer, and switching power supply. The transformer is used for isolation and step-down. The primary side of the transformer is connected to the AC power grid, and the secondary side is connected to the PWM rectifier; the PWM rectifier is used to realize AC / DC power conversion, and the DC output is connected to the DC contact network to provide DC power supply for rail transit vehicles; The control board completes the corresponding control by detecting the voltage and current of the AC side of the PWM rectifier and the voltage and current of the DC side, and sends out 6 PWM drive pulses to drive the power switch tube in the PWM rectifier to work, and implement the protection of the device at the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com