Gas generator device for recovering sensible beat of slag obtained from gas producer

A technology of gasifier and slag, which is applied in the field of chemical production and can solve problems such as waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

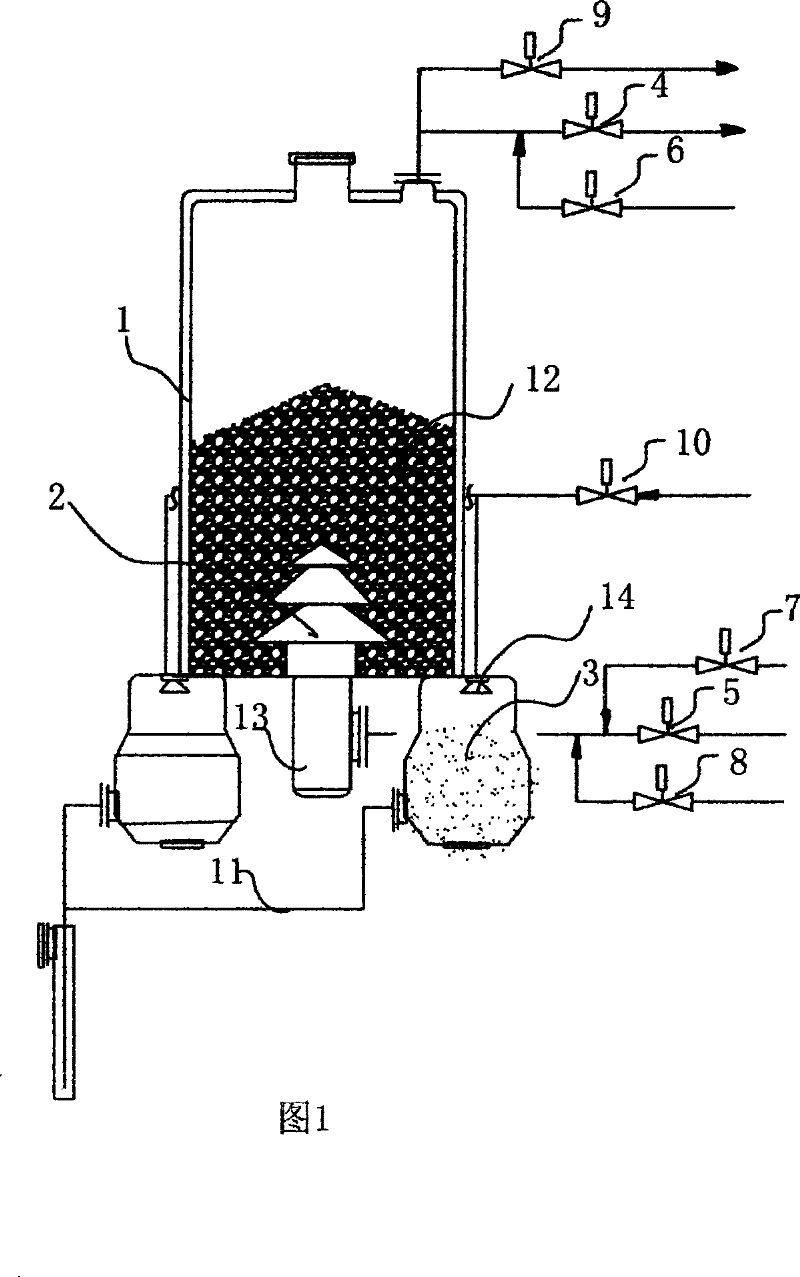

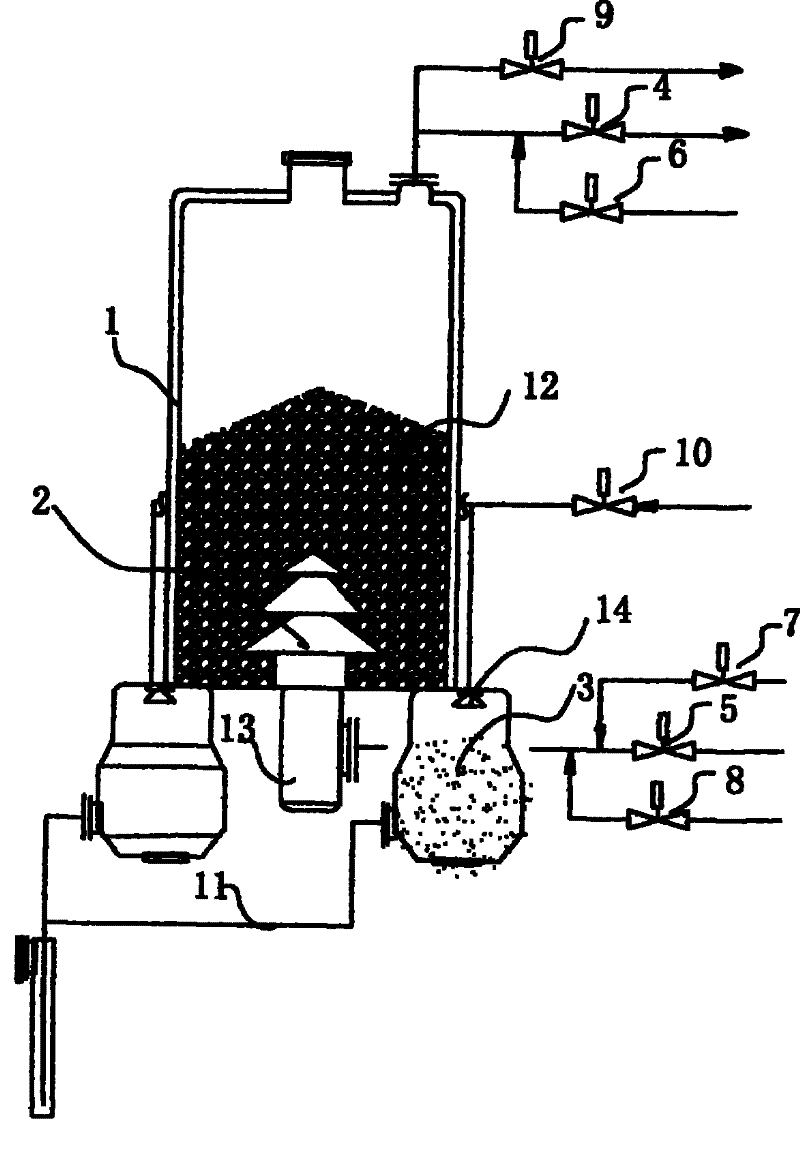

[0010] As shown in Figure 1, the gas generator device includes a furnace body 1, a grate 2, a slag chamber 3, an upward gas pipe valve 4, a downward gas pipe valve 5, a downward blowing steam pipe valve 6, and an upward blowing steam pipe valve 7 , blast air valve 8, vent valve 9, slag cooling water pipe valve 10, automatic overflow pipe 11, the lower part of the furnace body 1 is the combustion chamber 12, the tower furnace grate 2 is located in the combustion chamber 12, the tower furnace 2 passes through The air inlet sleeve 13 is respectively connected with the upward blowing steam pipe valve 7, the downward blowing gas pipe valve 5, and the blast air valve 8. The valve 9 is connected, the slag chamber 3 is located at the lower part of the combustion chamber 12, the upper part of the slag chamber 3 is connected with the slag cooling water pipe valve 10 through a water nozzle 14, and the upward blowing steam valve 7 and the slag cooling water pipe valve 10 are linked , sync...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com