Process of smelting iron pyrite

A pyrite and process technology, applied in the field of pyrite smelting process, can solve the problems of arsenic removal, incomplete sulfur, inability to recycle, high energy consumption, etc., achieve good comprehensive recovery effect, obvious energy saving effect, and solve environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

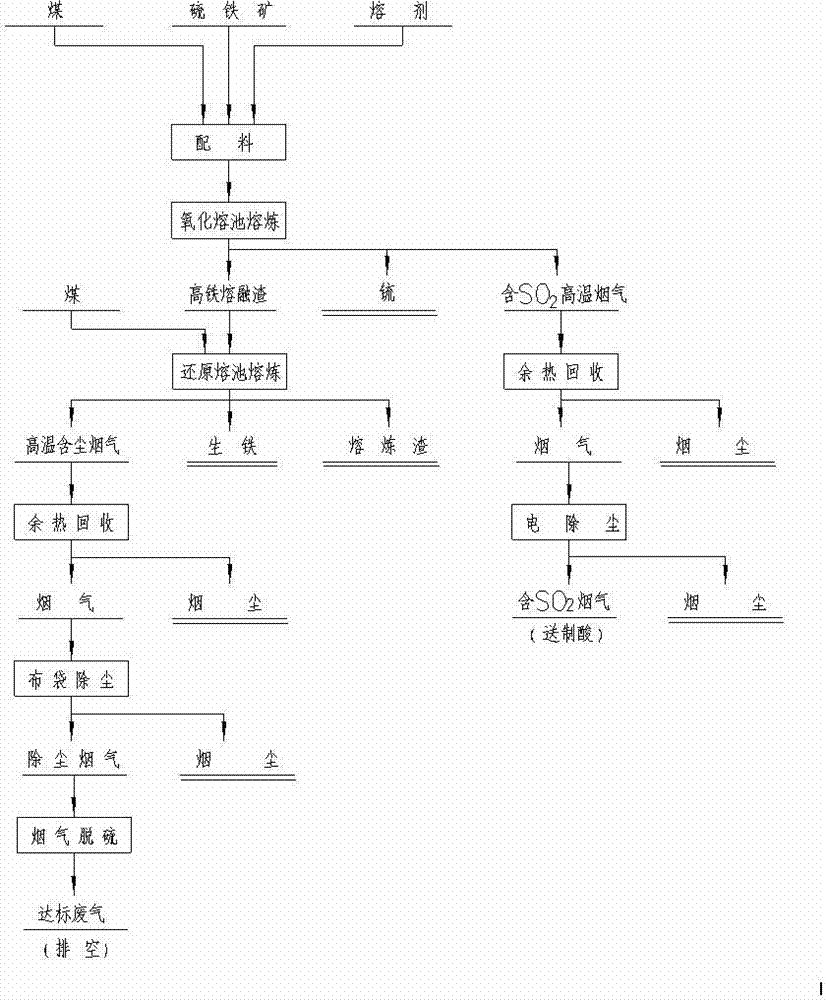

[0016] from figure 1 Can find out that technique of the present invention mainly comprises two operations:

[0017] 1) Oxidative smelting of pyrite: pyrite is smelted in an oxidation bath with oxygen-enriched air, and the obtained matte is rich in copper, gold, silver and other precious metals, which settles at the bottom of the furnace and is discharged from the siphon port at the furnace end, with low sulfur and arsenic content The smelting slag with high iron content is discharged from the slag outlet and sent to the reduction melting pool smelting furnace for reduction smelting. The reason why the present invention uses an oxidation melting pool to smelt pyrite is that the melting temperature of the melting pool is high, the slag temperature is usually higher than 1150°C, the arsenic removal effect is good, and the arsenic content is usually lower than 0.03%, and the generated matte has a large specificity and is incompatible with the slag , The molten slag after clarifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com