Double conical surface automobile synchronizer

A synchronizer and double-cone technology, which is applied in the direction of clutches, mechanically driven clutches, transmission parts, etc., can solve the problems of axial size occupied by the connecting structure, high processing difficulty, high cost, and high processing difficulty, and achieve processing difficulty and Low cost, reduced processing cost, and reduced processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

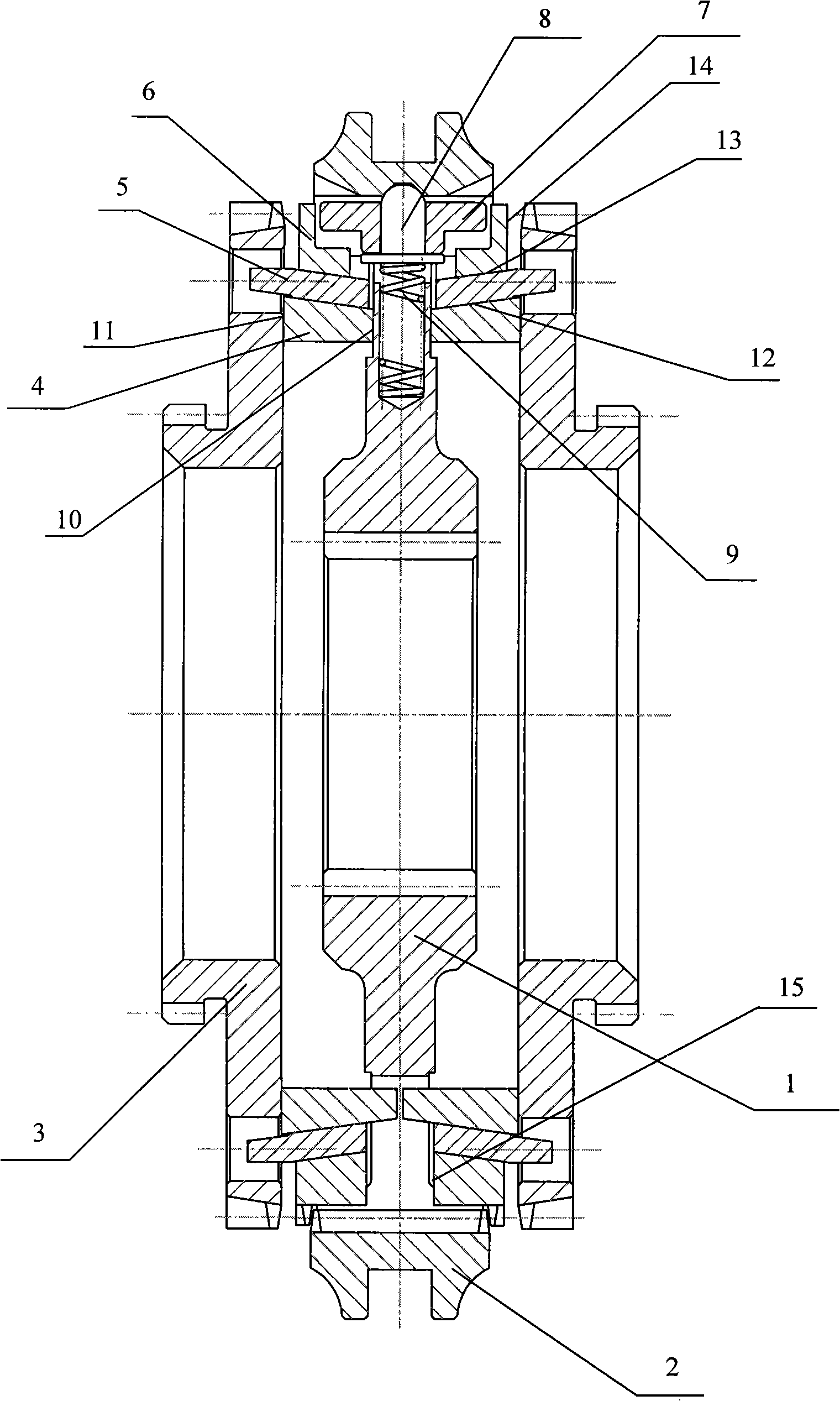

[0013] see figure 1 , the present invention comprises a gear hub 1, an inner friction ring 4 and an outer friction ring 6, the two sides of the friction cone surface 13 of the outer friction ring 6 are flush with the two end surfaces 14, 15 of the outer friction ring 6, and the friction cone surface of the inner friction ring 4 The two sides of 12 are flush with the two end surfaces 10 and 11 of the inner friction ring 4 , and the inner friction ring 4 is engaged with the gear hub 1 . The clamping method is that the inner friction ring 4 is provided with a protrusion on the end surface corresponding to the gear hub 1, and the end surface of the gear hub 1 is provided with a groove that can be nested and matched with the protrusion corresponding to the protrusion. Wherein the protrusion and the groove appear in pairs, which can be two or more pairs.

[0014] The working process of the present invention is as follows: the sliding gear sleeve 2 is driven by the shift fork to mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com