Side light type luminous diode backlight

A light-emitting diode and side-light technology, which is applied in the field of improved structure of side-light light-emitting diode backlight heat dissipation, can solve the problems of power increase and dissipation of light-emitting diode lamp groups, and achieve the effect of avoiding light leakage and improving heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

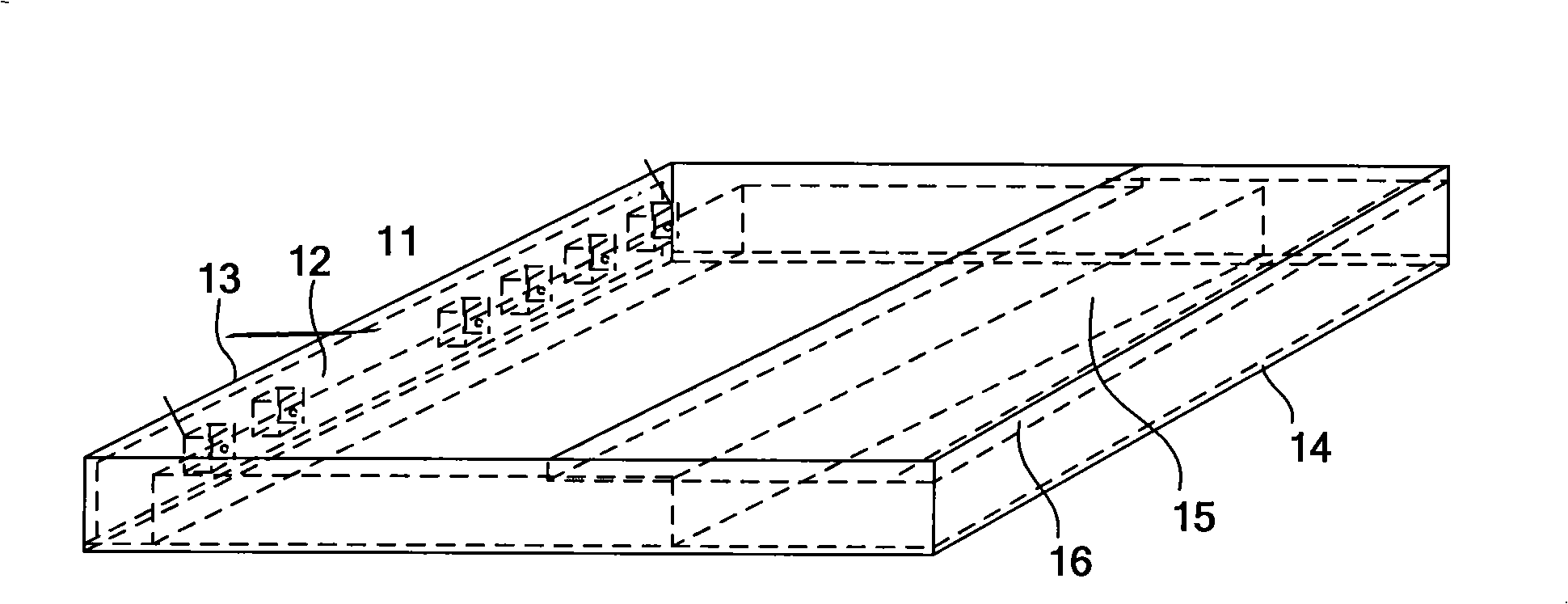

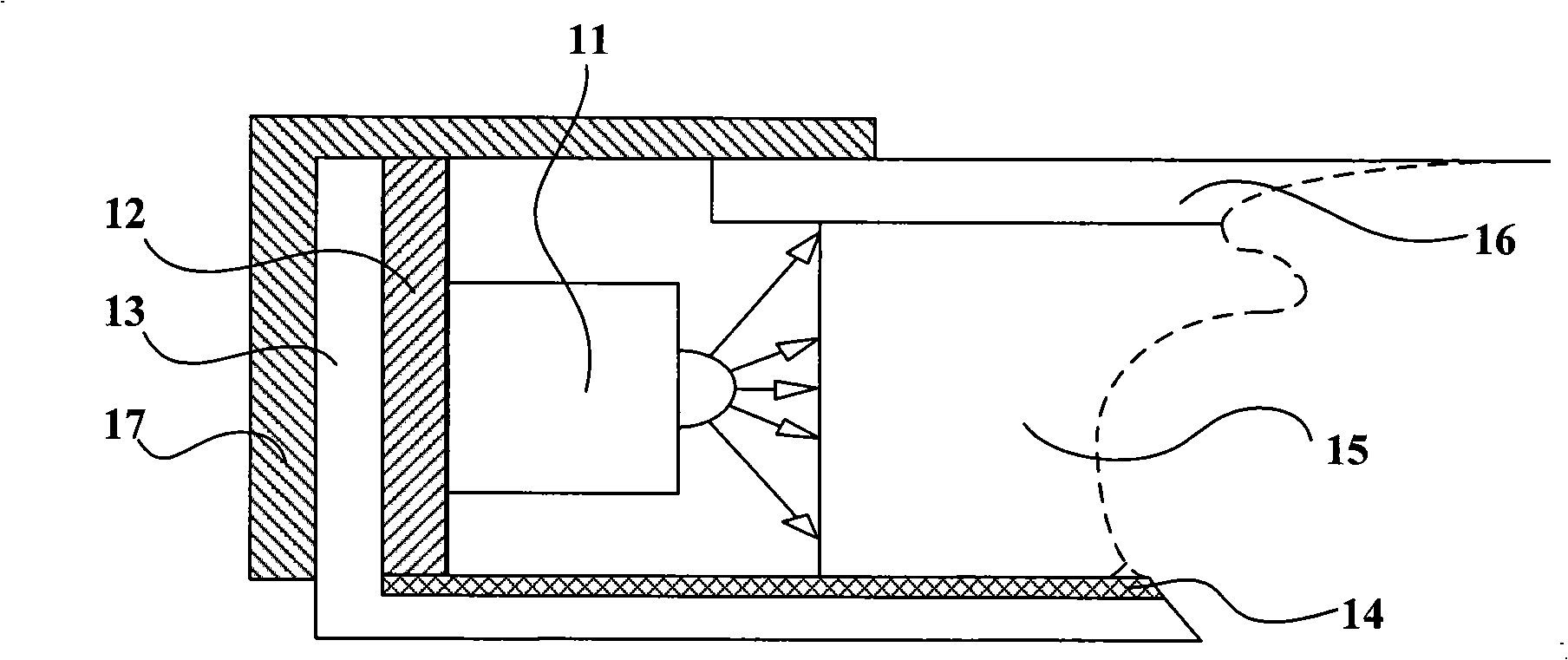

[0025] figure 2 Shown is a schematic cross-sectional view of Embodiment 1 of the side-light LED backlight source of the present invention, as figure 2 As shown, the side-light LED backlight source includes a LED lamp group 21, a circuit board 22, a back plate 23, a reflector 24, a light guide plate 25, an optical film group 26 and a frame 27; the LED lamp group 21 consists of a LED lamp The light-emitting diode is a top-emitting type, and the light-emitting diode lamp group 21 is directly welded on the circuit board 22, and the circuit board 22 is mounted on the inner side of the back plate 23; the light guide plate 25 is close to the upper surface of the lower side of the reflector 24; the optical film The group 26 covers the upper surface of the light guide plate 25, and the above-mentioned components are assembled together by the frame 27; the reflector 24 is L-shaped, and the top of the reflector 24 is connected with the optical film group 26, so that the reflective surf...

Embodiment 2

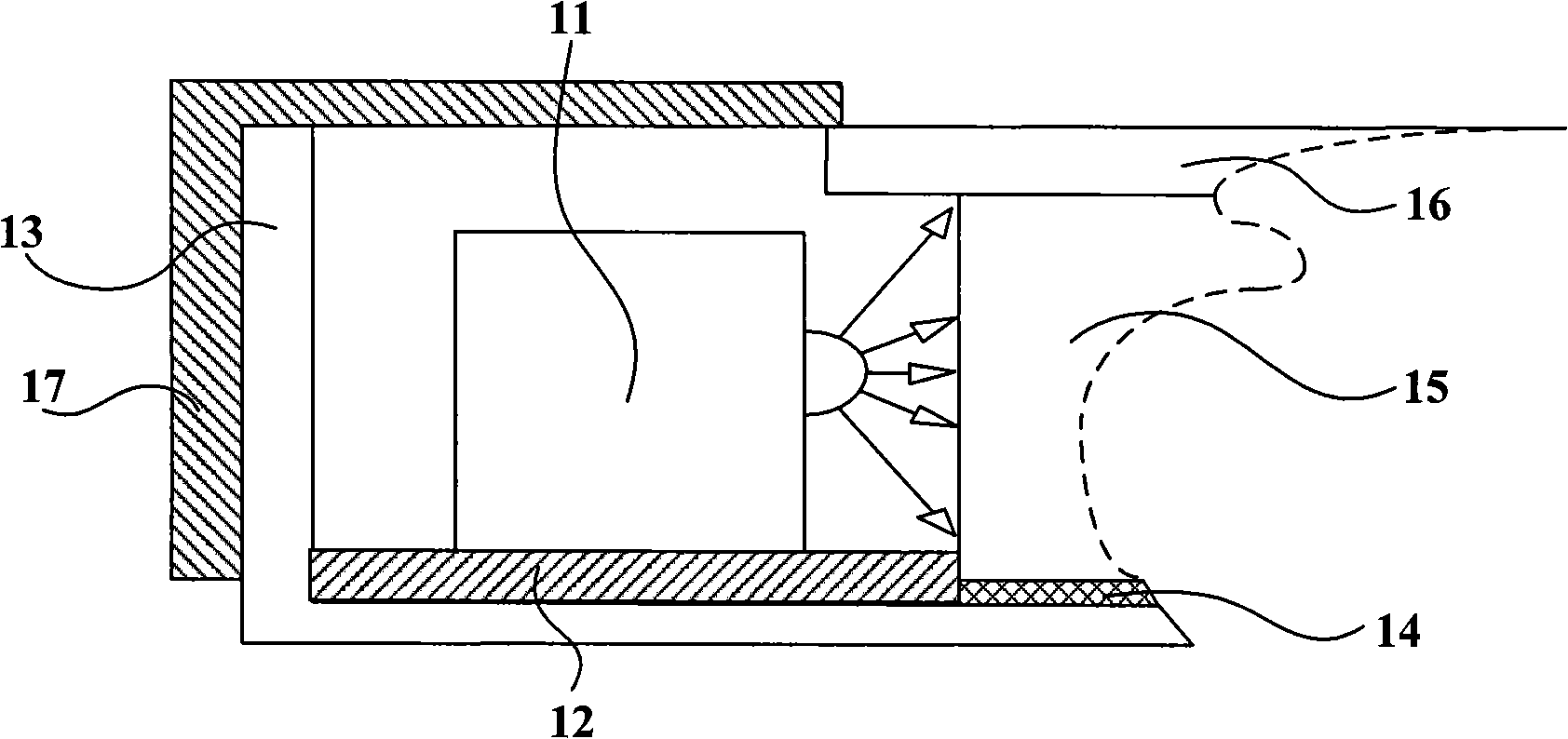

[0027] image 3 Shown is a schematic cross-sectional view of Embodiment 2 of the side-light LED backlight source of the present invention, as image 3 As shown, the side-light LED backlight includes LED lamp group 31, circuit board 32, back plate 33, reflector 34, light guide plate 35, optical film group 36 and frame 37; in this embodiment, the LED lamp group 31. The structural relationship between the frame 37, the back plate 33, the reflection plate 34, the light guide plate 35 and the optical film group 36 is the same as that in the first embodiment, the light guide plate 35 is close to the upper surface of the lower side of the reflection plate 34; the optical film group 36 covers the The upper surface of the light plate 35, therefore, the enclosed space is also the same as in Embodiment 1; the difference is that the LED lamp group 31 is made up of side-emitting LED lamps, therefore, the circuit board 32 for the power supply of the LED lamp group is mounted on The bottom ...

Embodiment 3

[0029] Figure 4 It is a schematic cross-sectional view of Embodiment 3 of the side-light LED backlight source of the present invention, as shown in Figure 4As shown, the side-light LED backlight includes a LED lamp group 41, a circuit board 42, a back plate 43, a reflector 44, a light guide plate 45, an optical film group 46 and a frame 47; in this embodiment, the LED lamp group 41. The structural relationship between the frame 47, the reflection plate 44, the light guide plate 45 and the optical film group 46 is the same as that in the first embodiment, the light guide plate 45 is close to the upper surface of the lower side of the reflection plate 44; the optical film group 46 covers the upper surface of the light guide plate 45 , Therefore, the enclosed space is also the same as in Embodiment 1; the difference is that the edge of the back plate 43 is n-shaped, the LED lamp group 41 is made up of top-emitting LED lamps, and the circuit board 42 for power supply of the LED ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com