Stretch break method and product

A technology of elongation at break, yarn, used in textile and paper making, fiber bundles into fiber strips/yarns, yarns, etc.

Inactive Publication Date: 2008-11-26

EI DU PONT DE NEMOURS & CO

View PDF18 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

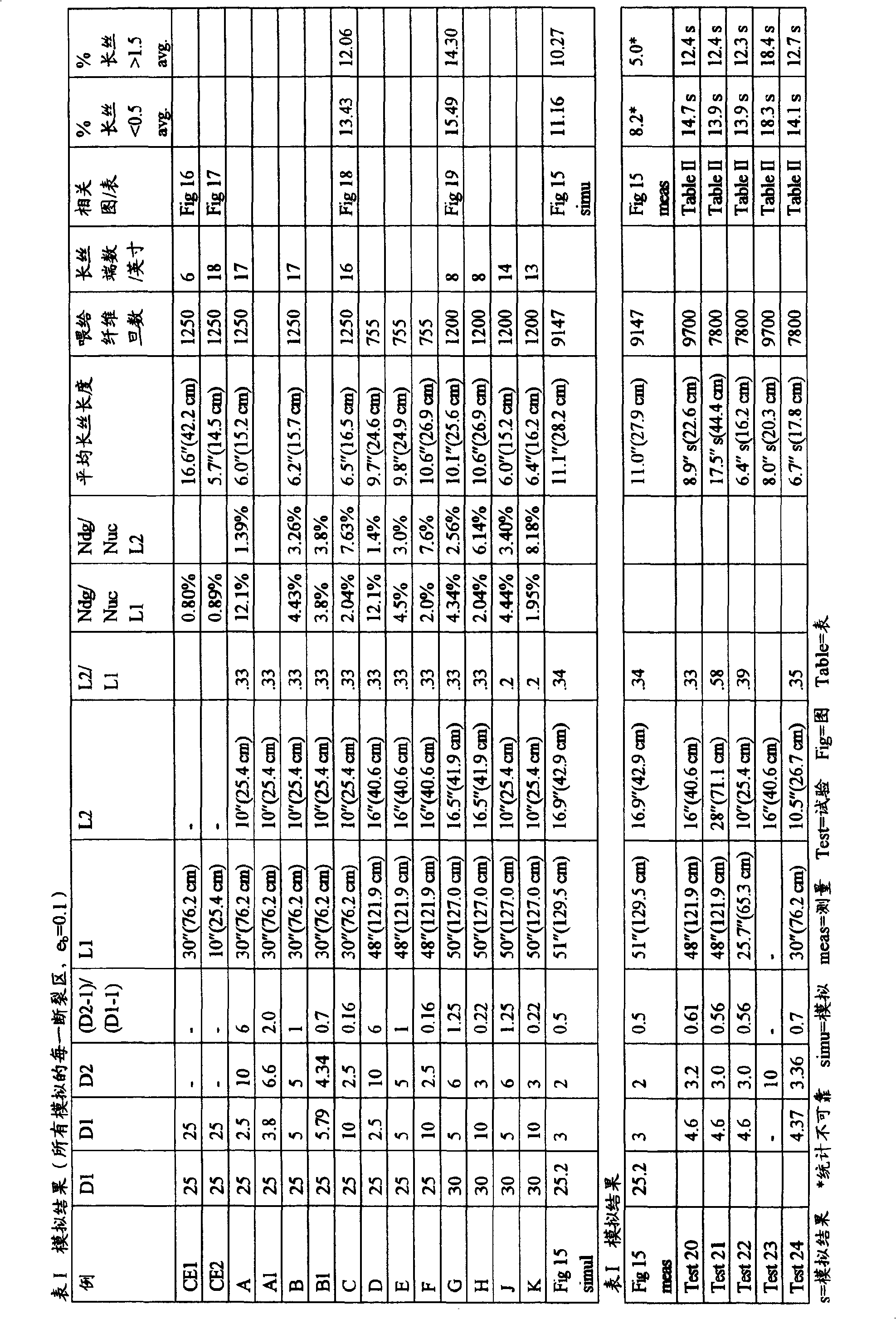

The problem with the product produced by Adams et al. is that 1.5-20% of the discontinuous filaments produced in a single breaking zone have a length of more than 76 cm and cause problems in further processing (mainly wrapping on rolls) ), especially when the selected process is not oriented vertically

This lack of control and the use of apron belts can limit the process rate to what it cites as 200 m / min, which is too slow for a commercial line of single low denier yarn

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Login to View More

Abstract

A method for stretch breaking fibers to produce a staple yarn and operating a staple fiber spinning machine that enables the production of a plurality of products of lot size smaller than a large denier tow product. The process includes at least two break zones and a consolidation zone downstream from a second break zone to form a staple yarn. The filaments are broken in a second break zone downstream from the first break zone by increasing the speed of the fiber fed into the process.

Description

This application claims priority to provisional application Serial No. 60 / 139,096, entitled "Stripping Methods and Products," filed on June 14, 1999. technical field This invention relates generally to a fiber conversion and spinning process, and more particularly to a method of breaking continuous filament fibers into discontinuous filament fibers and consolidating the fibers into yarns. technical background The spinning of synthetic staple fibers has been produced by cutting the continuous filaments into staple fibers and then forming yarns in the same way as cotton or wool fibers. The simpler direct spinning process is also used, in which parallel continuous filaments are stretched and drawn to form a discrete strand between feed and delivery rolls in what is sometimes referred to as the stretch or takeoff zone , and then twisted to form spun yarns, such as disclosed in US 2,721,440 to New or US 2,784,458 to Preston. This early process was slow because it was limited b...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D02G3/02D01G1/08D01H5/30D01H4/02D02J1/08D01D7/00D01H1/115

CPCD01G1/08

Inventor J·A·佩罗托P·波佩G·E·西蒙斯A·S·谭D·C·维瑟W·C·瓦尔克J·L·琼斯P·阿茨特H·米勒

Owner EI DU PONT DE NEMOURS & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com