On-line detection method for controlling station boiler combustion extinguishment

A detection method and technology of power plant boilers, applied in the field of combustion, can solve problems affecting safe operation, unsafe accidents, adjustment false appearances, etc., and achieve the effect of realizing safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

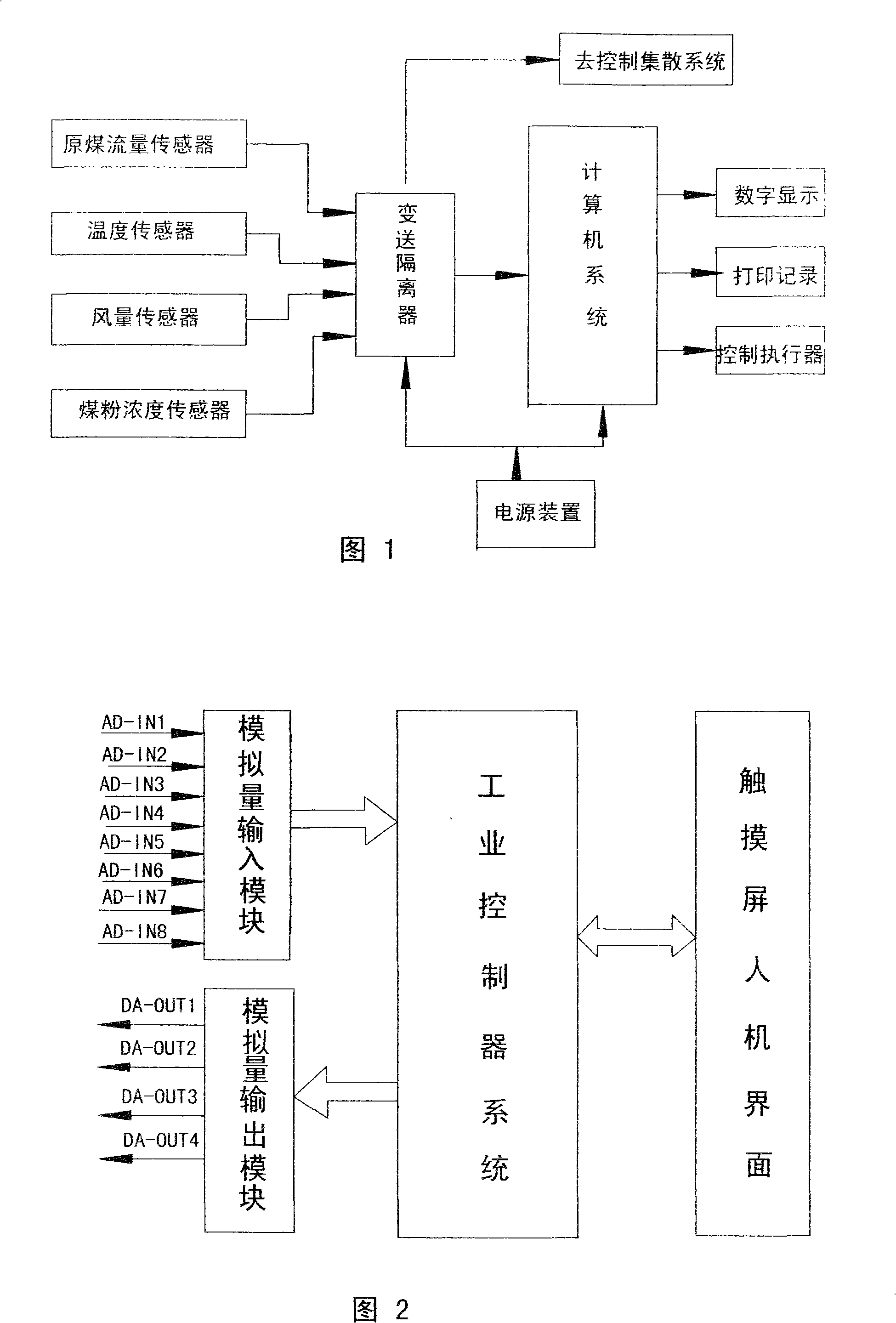

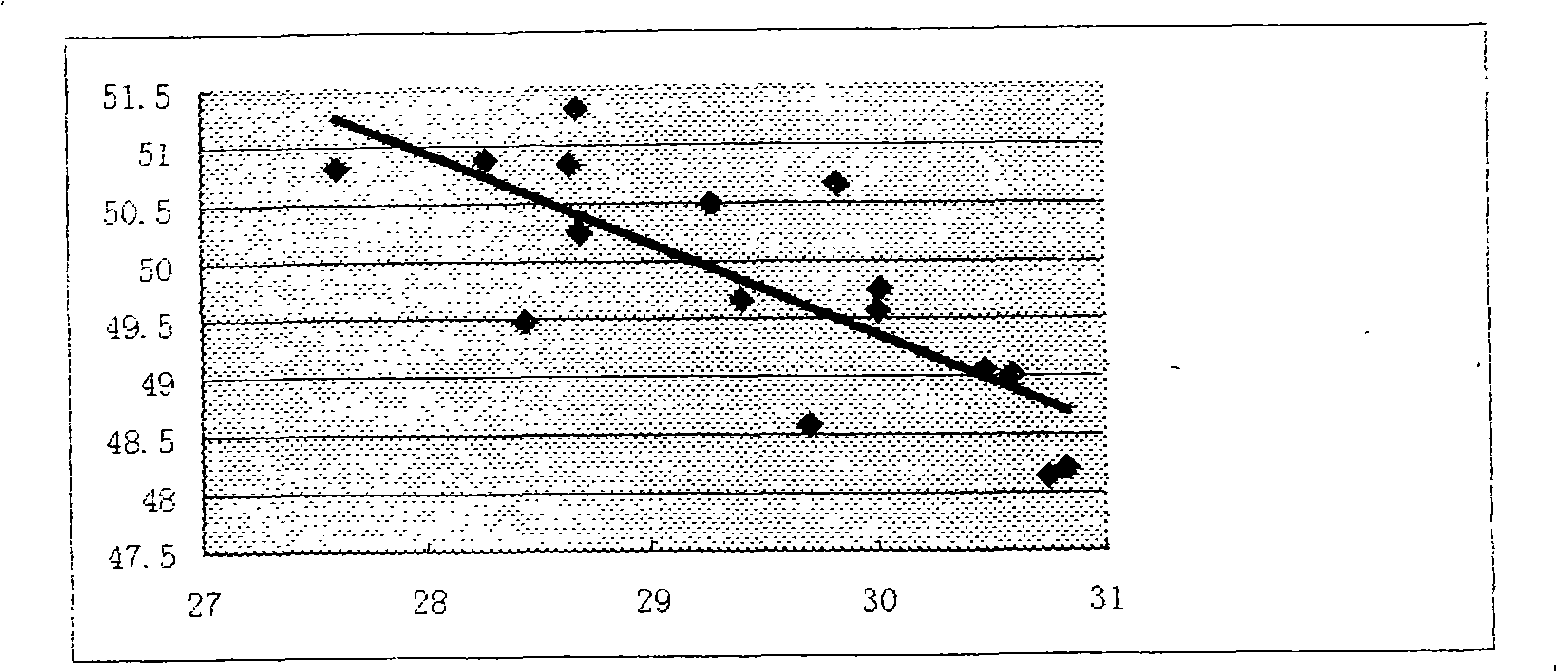

[0023] The equipment used in this online detection method for controlling the combustion and fire extinguishing of power plant boilers is a special equipment. The basic principle is still the electrostatic principle. The whole detection process maintains the practice of sampling, transmission and data processing. The difference is that the detection objects are different. And online actual measurement, and its detection method is a relative comparison method. Although the selected signal acquisition is multi-faceted, the internal change law of carbon content is constant. The data processing flow and algorithm rule determined thereby It is different from previous methods of measuring concentration and flow.

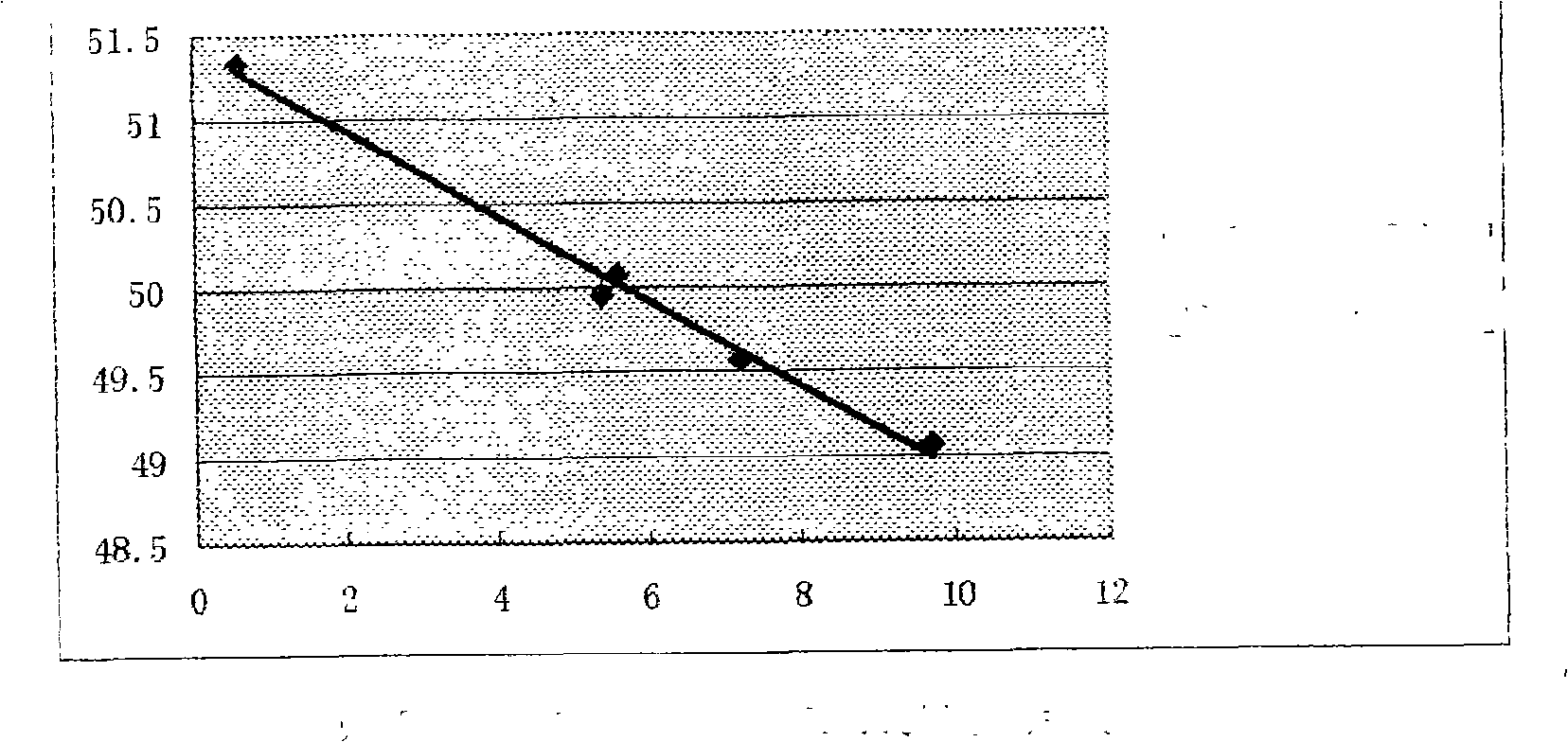

[0024] The basic starting point of this detection method is still to analyze the industrial composition of coal powder, and its essential improvement is online measurement, through analysis and comparison to find out the carbon content of coal powder, so as to strengthen op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com