An integrated light emitting diode die/lens structure, and process for the preparation thereof

A technology of light-emitting diodes and integral structures, which is applied in the manufacture of semiconductor/solid-state devices, electric solid-state devices, semiconductor devices, etc., can solve problems such as cracking of lens materials, peeling off of lens materials and supporting structures, and reduced long-term reliability of LEDs, etc., to achieve The effect of ensuring long-term reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0070] Prepare a liquid silicone rubber composition (at 25°C, viscosity 10Pa·s) according to the following steps:

[0071] [Chem 2]

[0072]

[0073] (where L=450)

[0074] In 100 parts of dimethyl polysiloxane whose two ends are blocked by vinyl dimethyl siloxy groups, add the following formula (ii)

[0075] [Chem 3]

[0076]

[0077] (where L=10, M=8)

[0078] The organohydrogenpolysiloxane represented by , so that the molar ratio of the SiH group to the vinyl group in the above-mentioned vinyl group-containing dimethylpolysiloxane (i) reaches 1.5, and then add 0.05 parts of chloroplatinic acid Octanol modified solution, stir well.

[0079] Next, a support structure in which 24 LED chips were mounted on an alumina substrate was prepared.

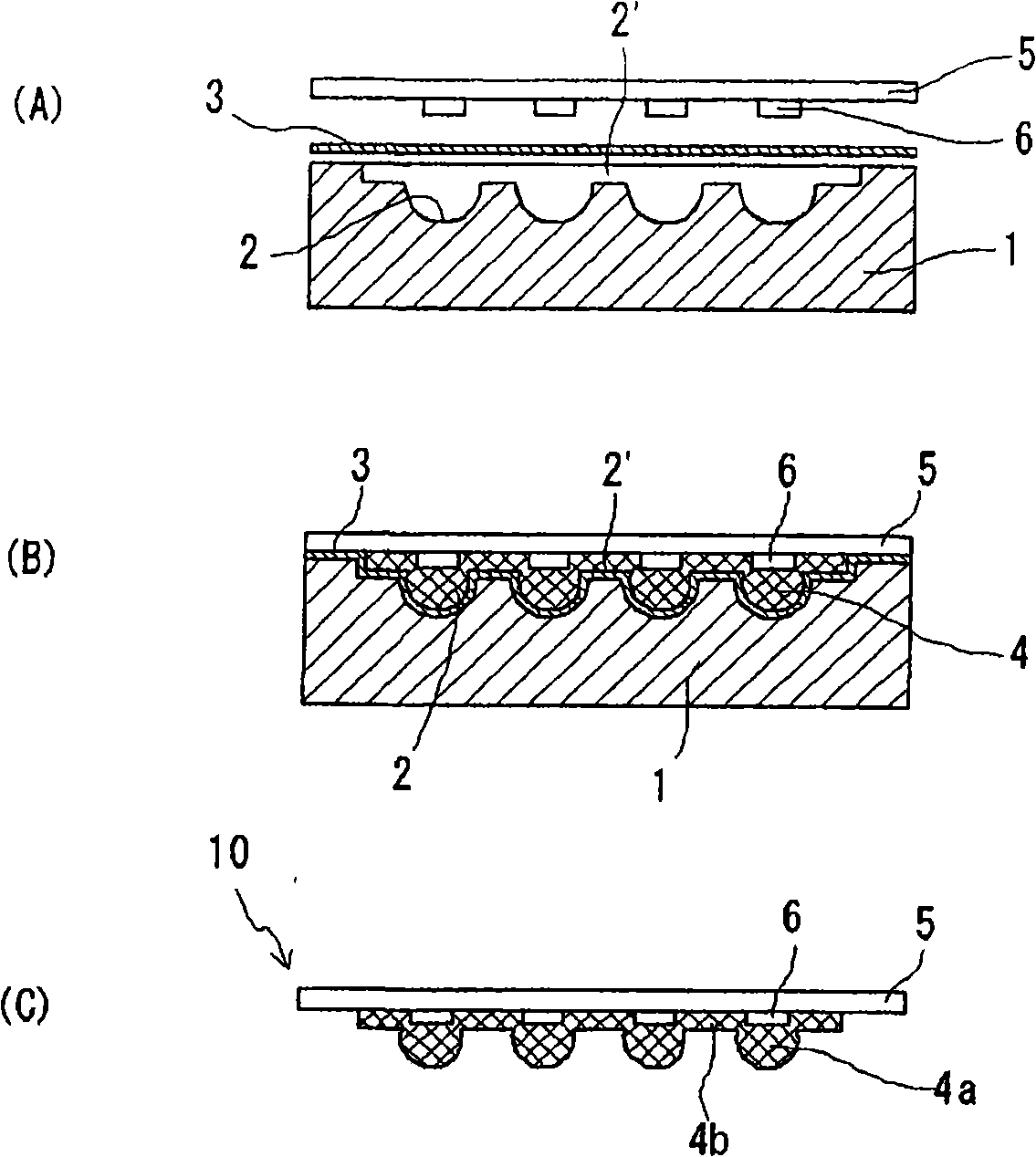

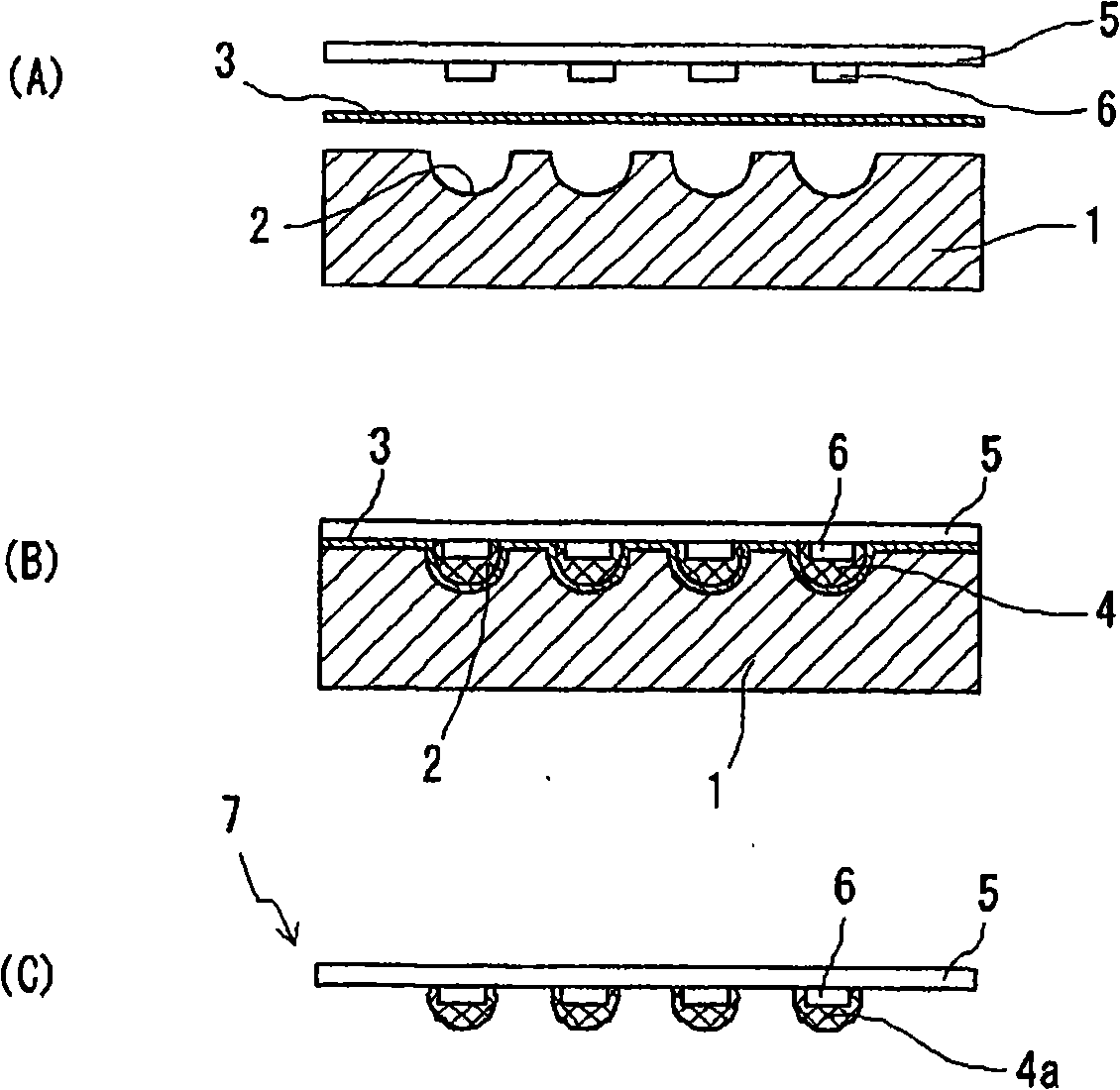

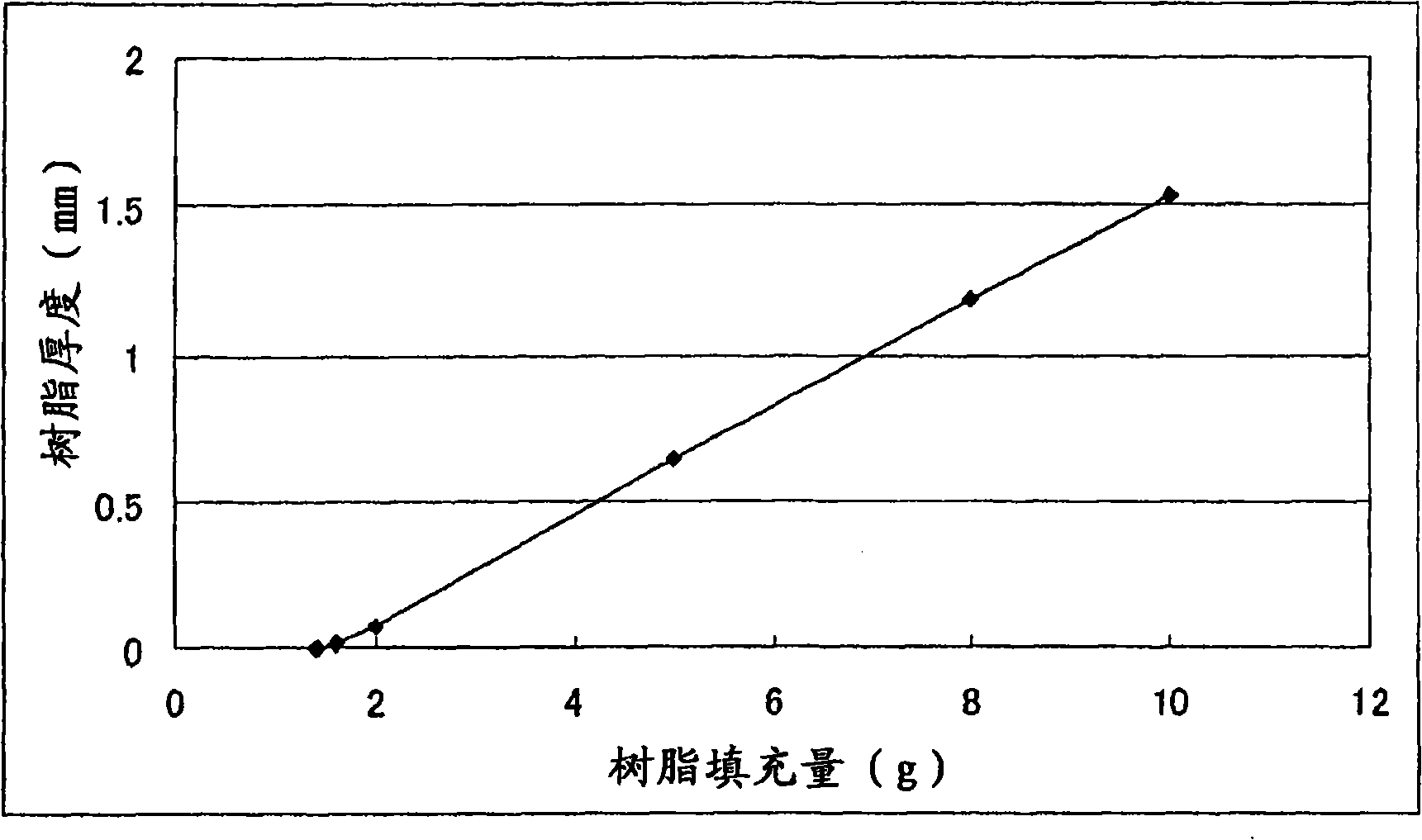

[0080] On the other hand, along figure 1 The concave mold cavity shown and the two mold cavities of the mold with a thickness of 0.01 to 2 mm are placed on the two mold cavities made by Nitto Denko Co., Ltd., and 1.8 g, 2.0g, 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com