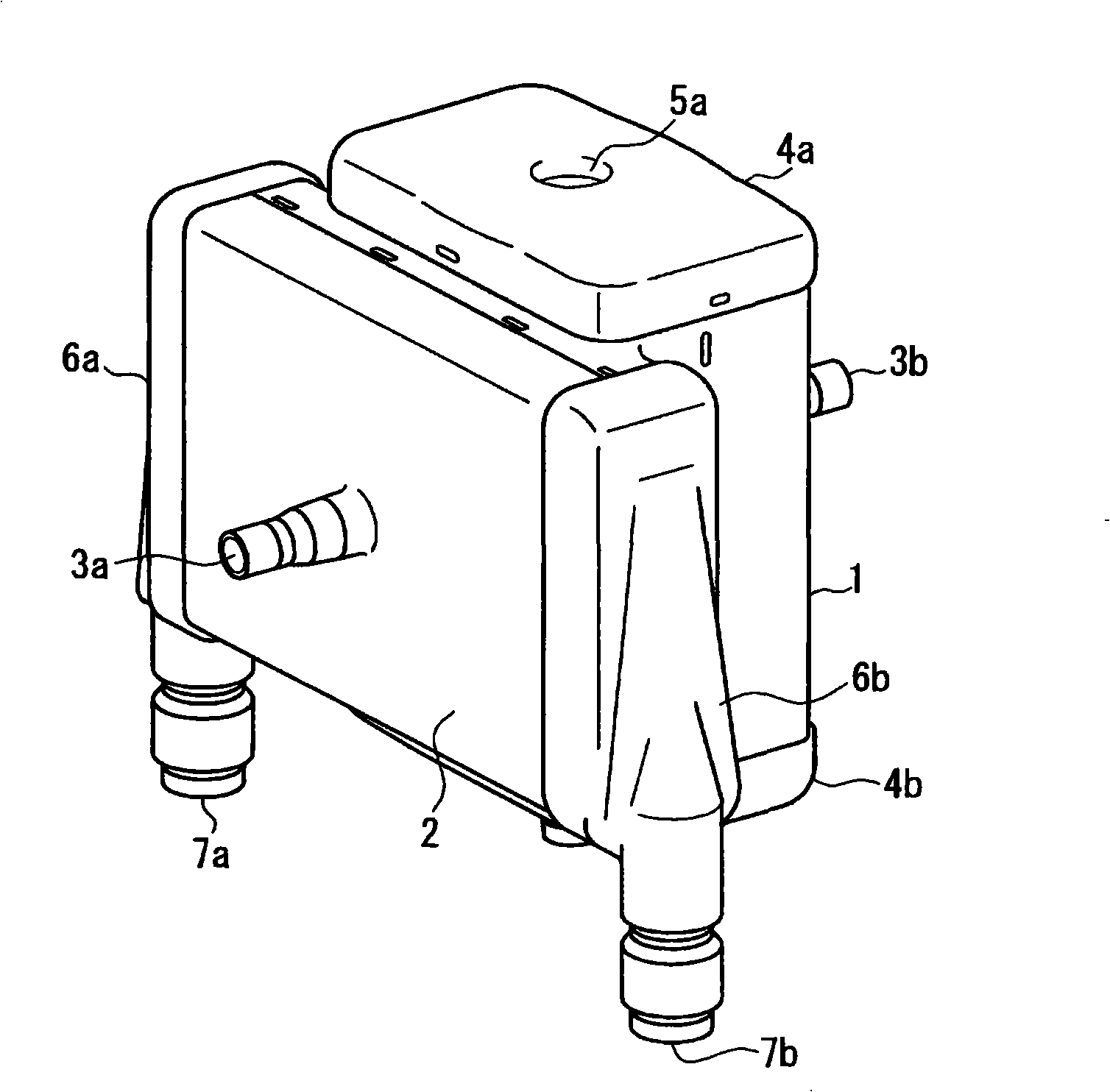

Hollow fiber membrane type artificial lung

A fiber membrane, artificial lung technology, applied in the field of hollow fiber membrane artificial lung, can solve problems such as increased blood filling volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

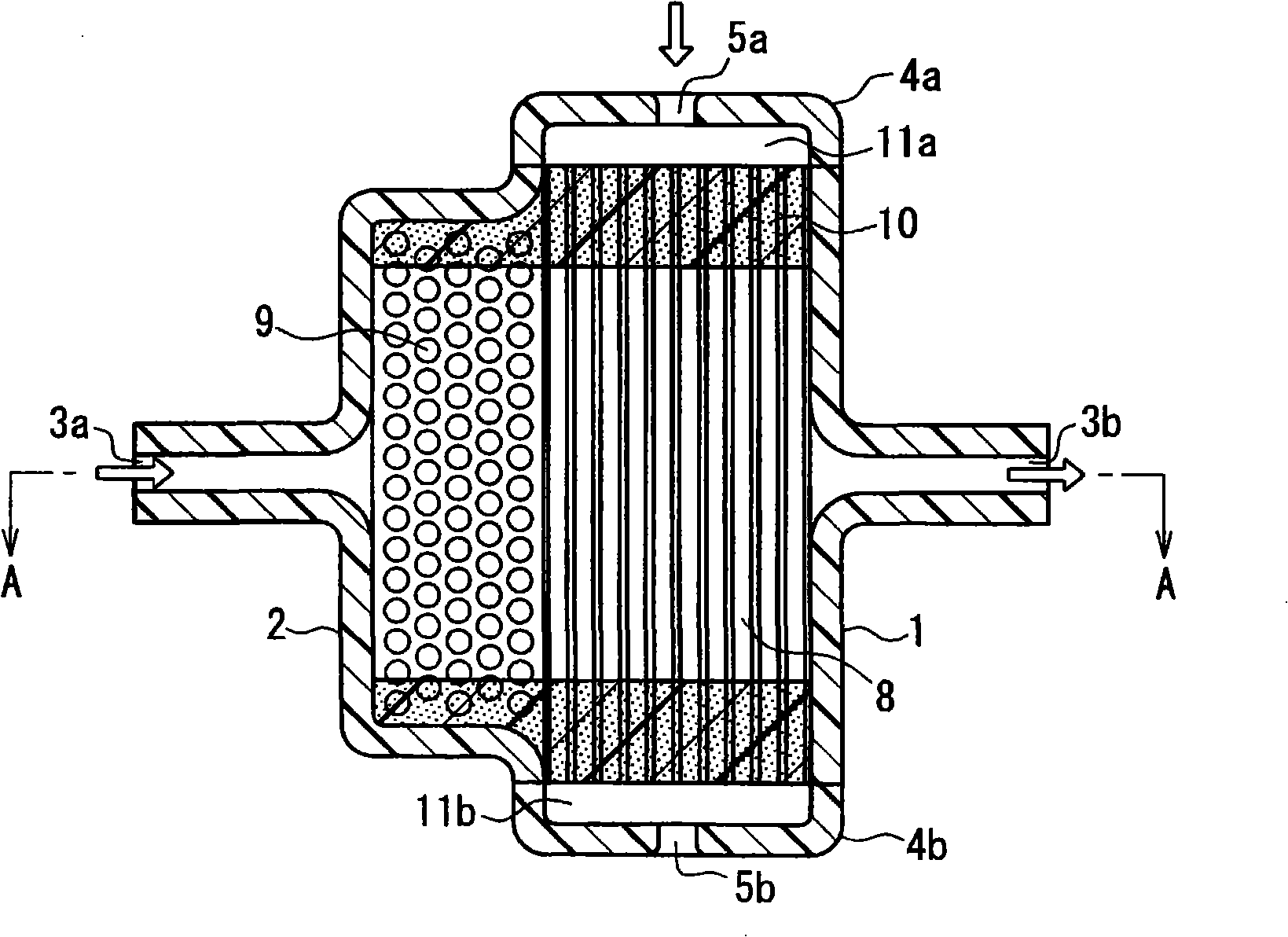

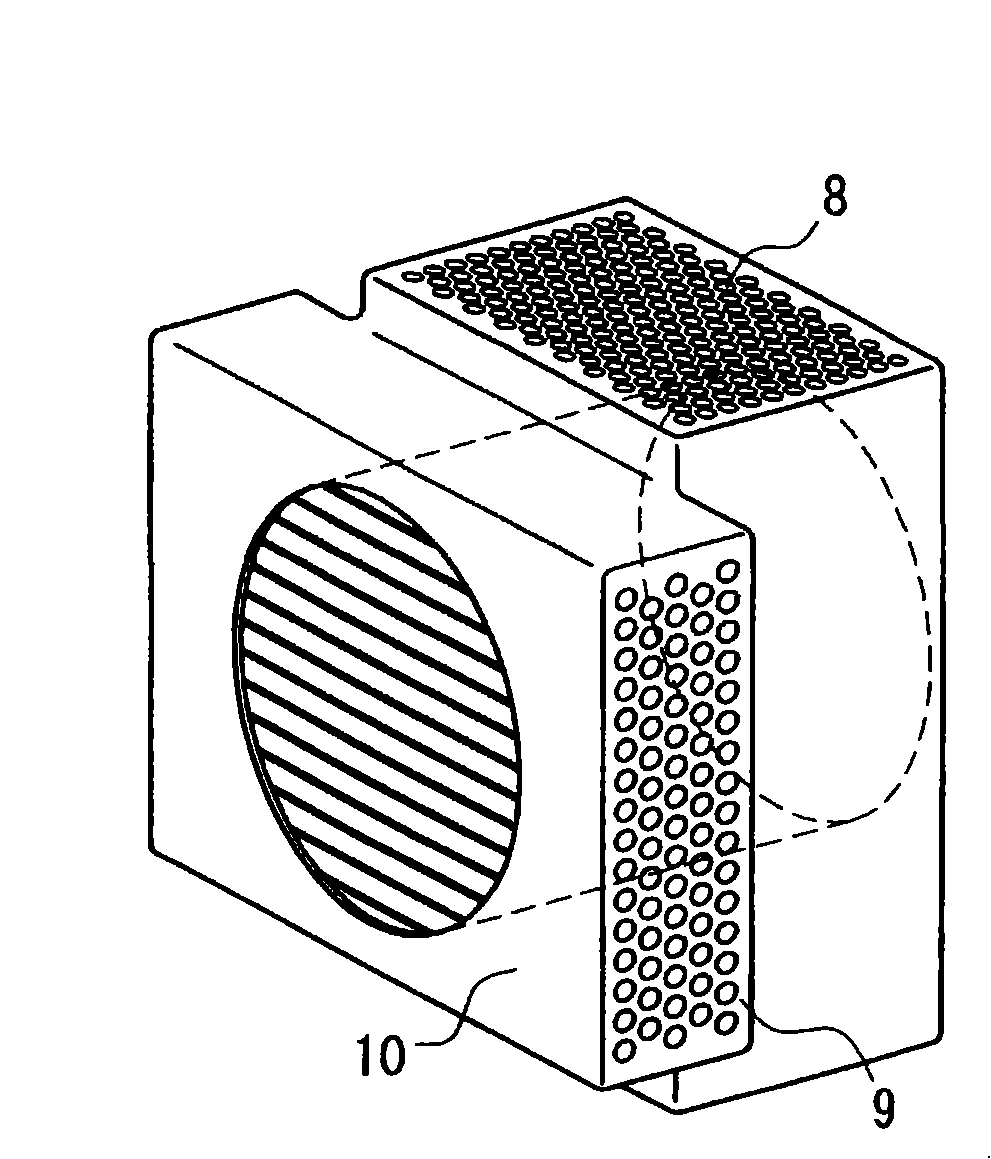

[0035] In the hollow fiber membrane type artificial lung of the present invention having the above structure, it is preferable that the arrangement direction of the heat exchange tubes constituting the heat exchange tube bundle is perpendicular to the arrangement direction of the hollow fiber membranes constituting the hollow fiber bundle.

[0036] Further, it is preferable that the heat exchange liquid inlet passage and the heat exchange liquid outlet passage formed by the heat exchange header are formed in the same direction as the gas outlet passage. The reason for this is as follows.

[0037]By arranging the gas outlet channel downward, even when the inner cavity of the hollow fiber membrane is blocked by water droplets due to dew condensation, it is possible to prevent the inner cavity of the hollow fiber membrane from being blocked by water droplets. This is because the flow direction of the gas is the same as the direction in which the water droplets fall, so that the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com