Ultrasonic atomization atmospheric-pressure glow-discharge ionization apparatus

A glow discharge and ultrasonic atomization technology, applied in the field of mass spectrometry analysis, can solve the problems of difficult to achieve real-time online monitoring, unsatisfactory actual effect, poor operability, etc., to improve ionization efficiency and ion transmission efficiency, and improve instrument analysis. Sensitivity, small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

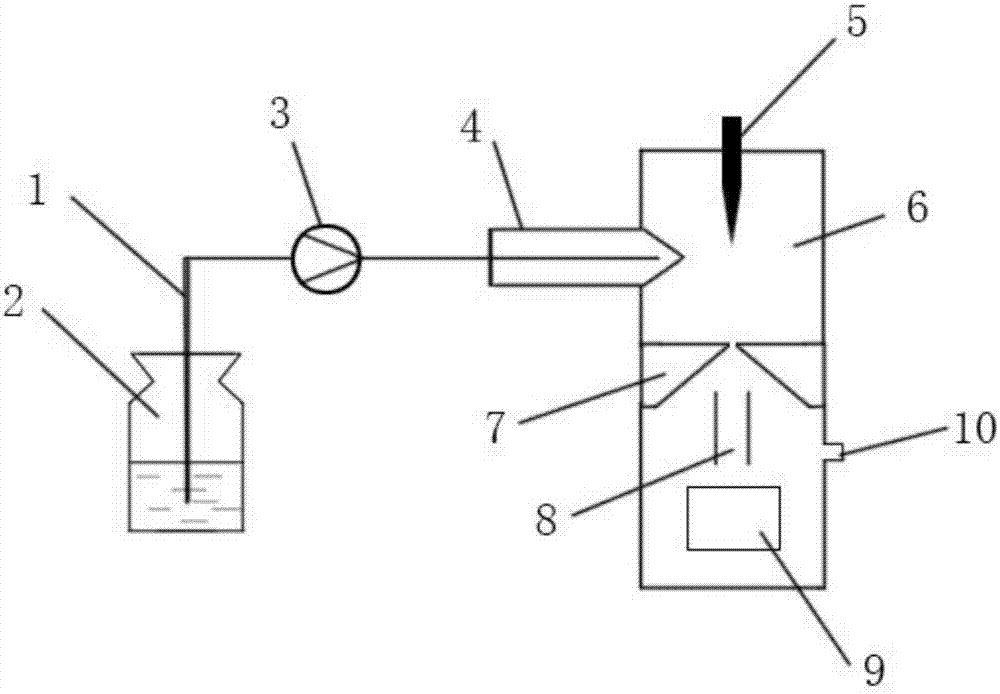

[0032] see figure 1 shown.

[0033] A liquid sample atmospheric pressure glow discharge ionization mass spectrometry device for ultrasonic atomization sample injection, comprising a sample injection device, an atmospheric pressure glow discharge ionization source and a mass spectrometer. The sampling device includes a sampling tube (1), a sample container (2), a liquid feeding pump (3) and an ultrasonic spray device (4). The sampling tube is connected with the sample container and the liquid feeding pump, and the liquid feeding pump is used to extract liquid For the sample water sample, the outlet end of the inlet pump is connected to the ultrasonic spray device; the atmospheric pressure glow discharge ionization source includes a discharge needle (5), a high-pressure glow reaction chamber (6) and a mass spectrometer injection cone (7). The device is vertically connected with the high-pressure glow reaction chamber. The discharge needle is set at the upper end of the high-pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com