Industrial production breed system for bumblebee

A kind of industrialization and beehive technology, applied in the field of bumblebee breeding, can solve the problems of being unable to use greenhouse plants for pollination, and there is no large-scale factory production and breeding of bumblebees, so as to save manpower, avoid direct contact and reduce mortality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

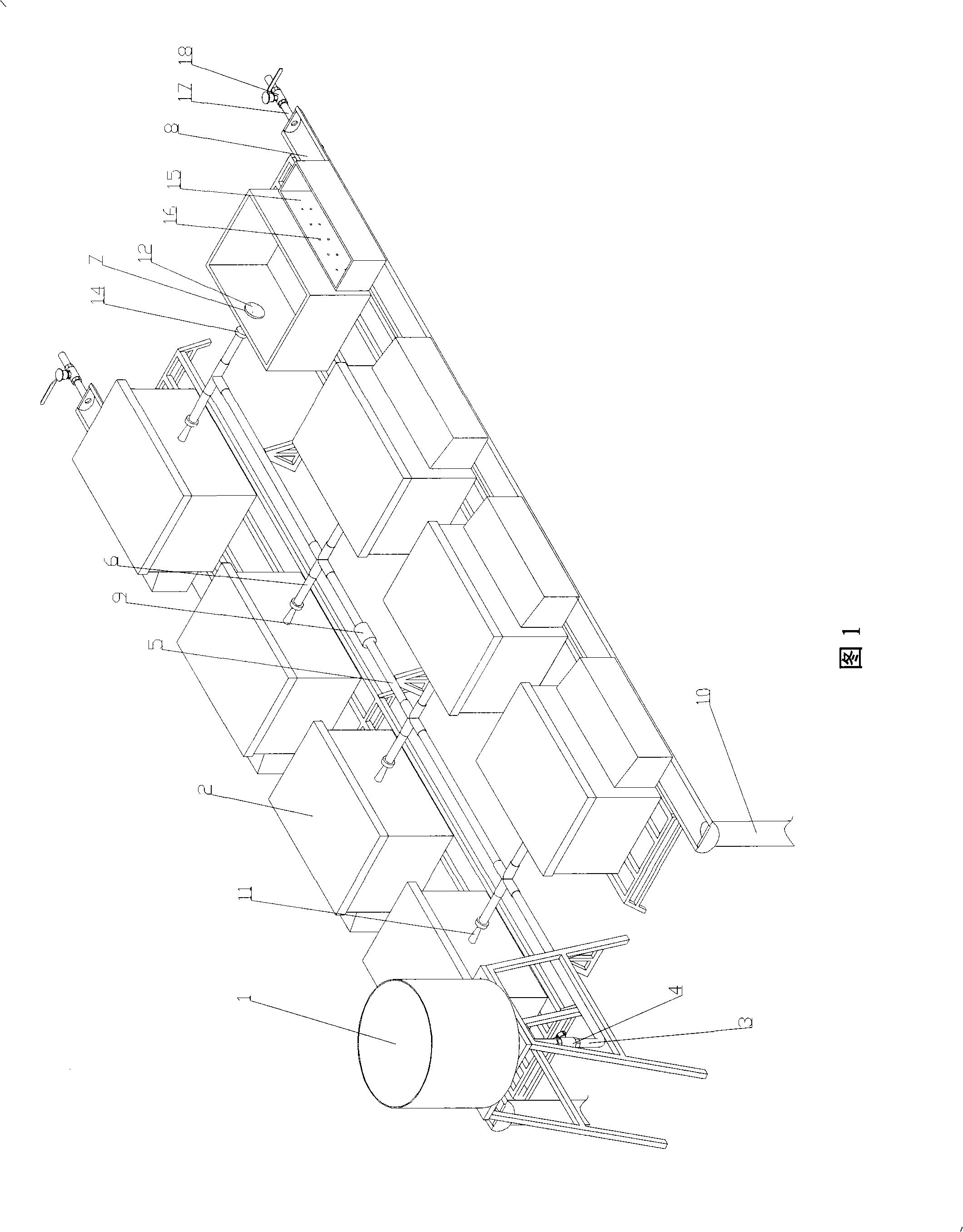

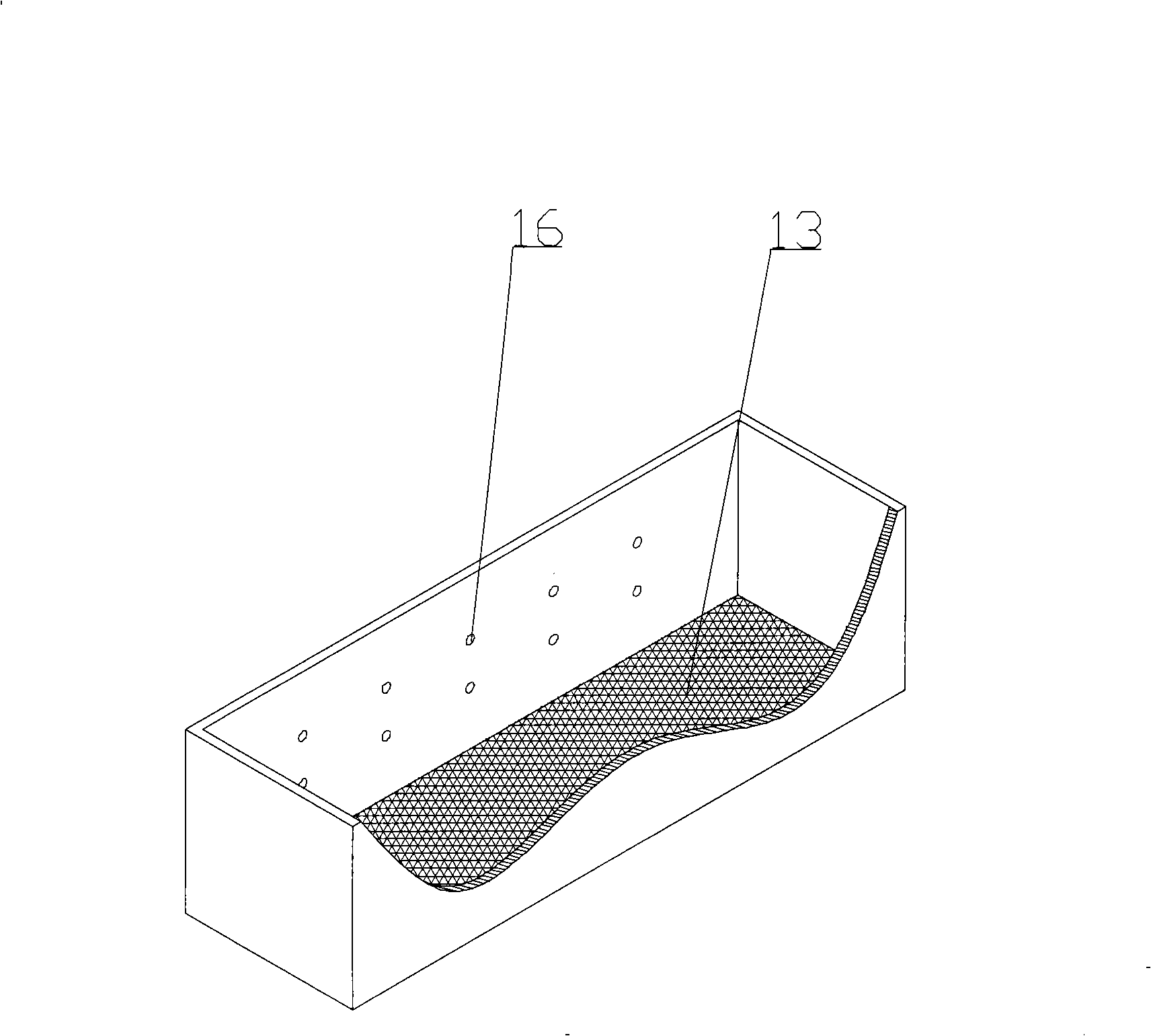

[0016] As shown in Figure 1, this example is a bumblebee production and breeding system with a multi-layer structure, which includes a feeding system and an excrement cleaning system. Above the multi-layer shelf is a nutrient solution tank 1, the nutrient solution tank 1 is connected to the horizontal pipeline (main pipeline) 5 of each layer by the vertical pipeline 3, the main pipeline 5 links to each other with the side pipeline 6, and the side pipeline 6 is connected to the feeding One end of the feeder 7 is a sponge body 12, which is located in the beehive 2, and the other end is a protruding kiss-like structure 11. The interface of the side pipe 6 (connected with the feeder) has a rubber Plug 14, the kiss-like structure 11 pierces the rubber plug 14 and communicates with the side pipe 6. A liquid level sensor 9 is arranged in the main pipe 5 , and a valve 4 is arranged in the vertical pipe 3 , and the valve 4 is controlled by the liquid level sensor 9 . The bees suck the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com