V type engine and cooling system thereof

A technology of engine and coolant, which is applied in the direction of engine cooling, engine components, machines/engines, etc. It can solve problems such as water leakage and complicated engine assembly, and achieve the effects of saving assembly procedures, facilitating cold start, and reducing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

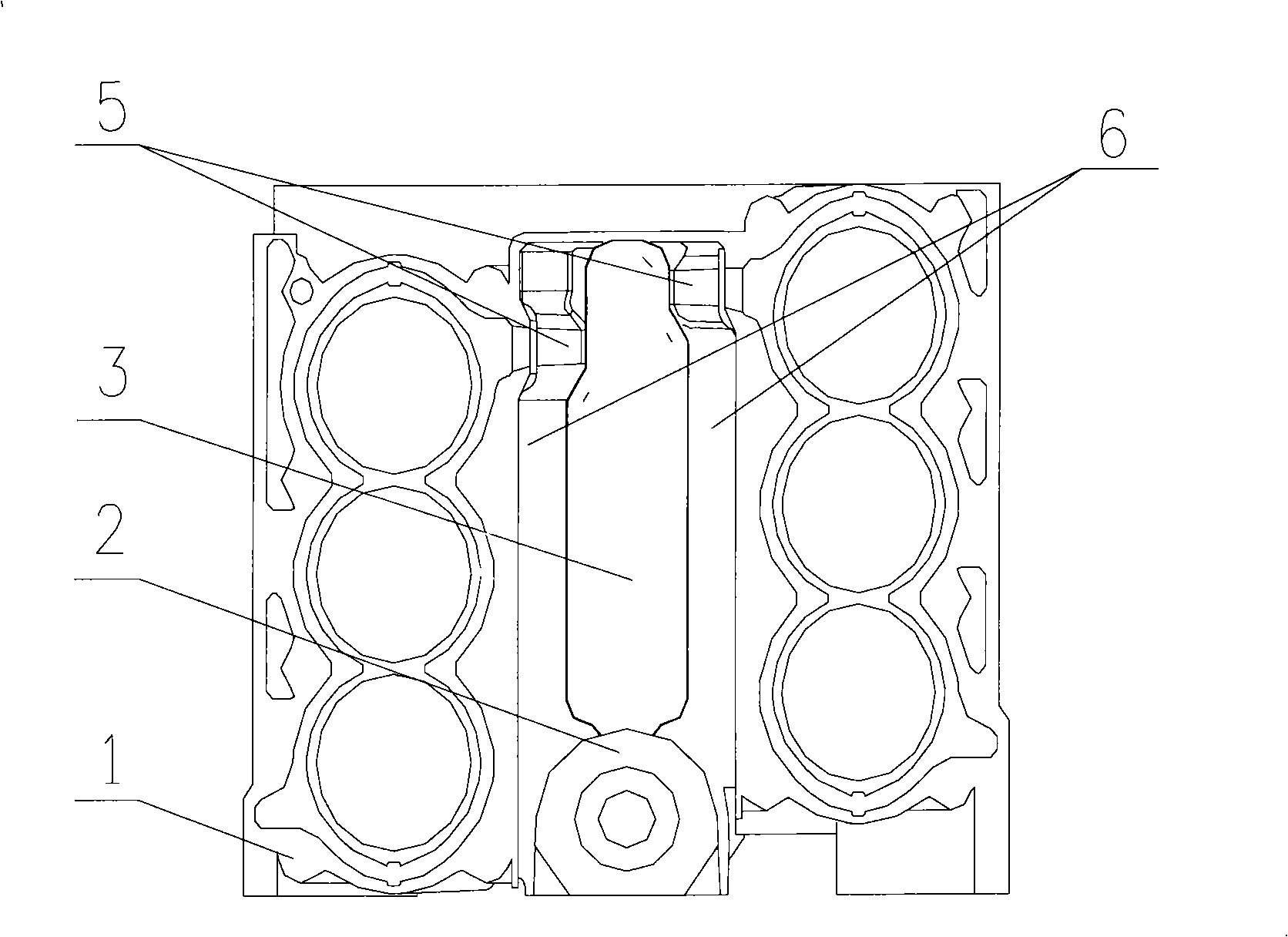

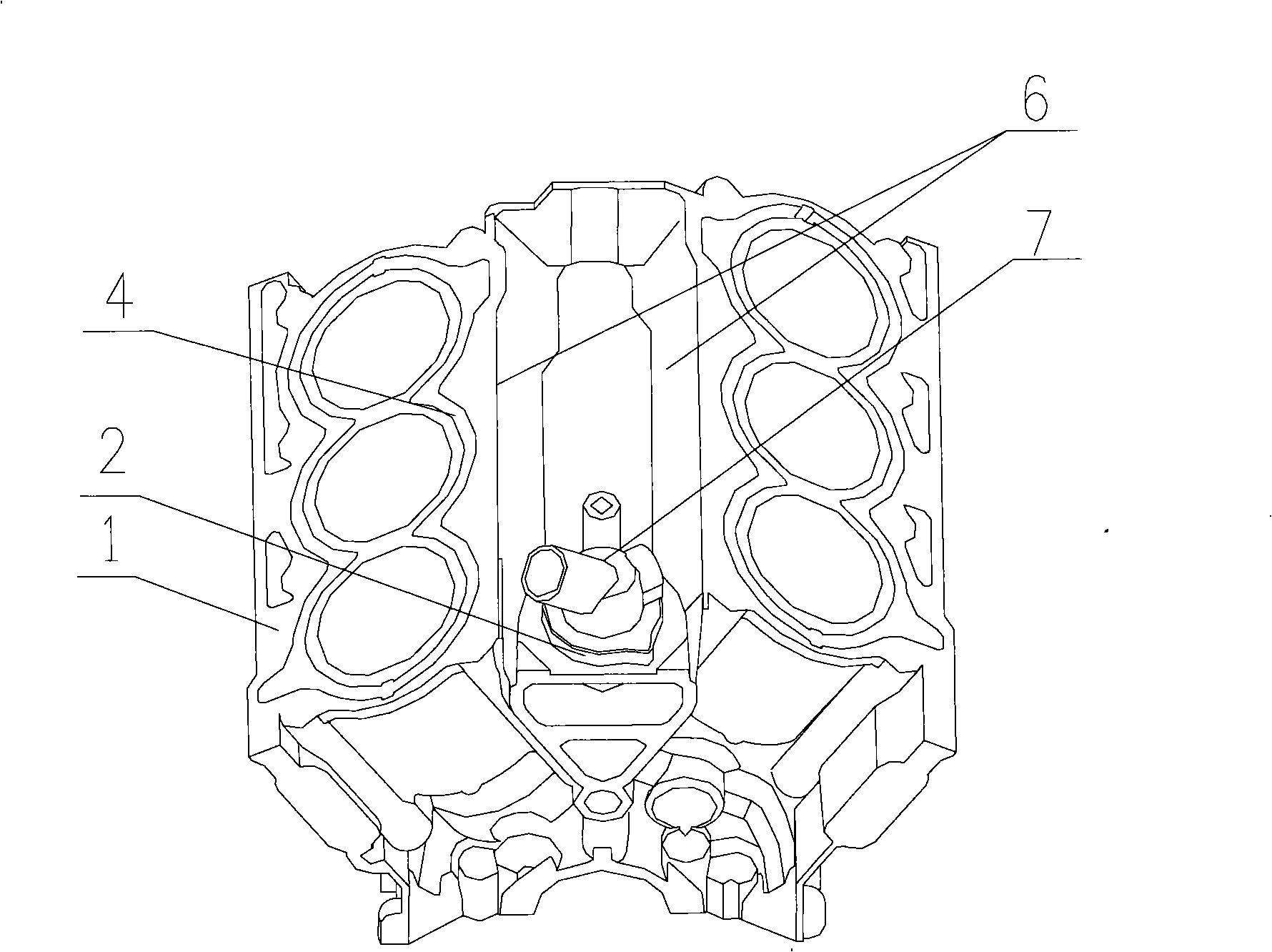

[0023] Such as figure 1 , 2 3, the V-shaped cylinder block 1 of the V-type engine of this embodiment is provided with a cylinder block water jacket 4, and the cylinder head is provided with a cylinder head water jacket (the cylinder head is not shown in the figure). The cylinder block water jacket 4 communicates with the cylinder head water jacket, and the V-angle area 6 of the cylinder block 1 is integrated with a thermostat seat 2 and an auxiliary water channel 3, and both ends of the auxiliary water channel 3 are connected with the thermostat respectively. The water inlet of the seat 2 communicates with the water outlet 5 of the water jacket 4 of the cylinder block.

[0024] Integrating the thermostat seat 2 and the auxiliary water channel 3 in the V-angle area 6 of the cylinder block 1 eliminates the need for additional installation of the thermostat seat 2, which reduces engine parts and saves the process of engine assembly; the auxiliary water channel 3 Instead of connectin...

Embodiment 2

[0029] Such as Figure 4 As shown, the cooling system of this embodiment applied to the V-engine of the above-mentioned embodiment 1 includes a cylinder block water jacket 4 and an auxiliary water channel 3 in the cylinder block, a cylinder head water jacket 41 in the cylinder head, a radiator 8, and a water pump 9 and the thermostat 7 fixed on the cylinder block thermostat seat, the cylinder block water jacket 4, the cylinder head water jacket 41, the auxiliary water channel 3, the thermostat 7, the radiator 8 and the water pump 9 are connected to form a large circulation Channel, the cylinder water jacket 4, the cylinder head water jacket 41, the auxiliary water channel 3, the thermostat 7 and the water pump 9 are connected to form a small circulation channel.

[0030] When the temperature of the engine coolant rises to the set temperature, the main valve 71 of the thermostat 7 opens, the bypass valve 72 closes, and the coolant circulates in the large circulation channel; when t...

Embodiment 3

[0034] The cooling system of this embodiment applied to the V-type engine of the first embodiment is different from that of the second embodiment in that the radiator 8 is connected with a sub-tank 11 to prevent loss of coolant.

[0035] The radiator 8 is connected to the auxiliary water tank 11 through a pressure valve 10 and an overflow pipe provided on the top of the radiator 8. The upper part of the auxiliary water tank 11 is in communication with the atmosphere. When the steam pressure in the radiator 8 rises to a set value, The pressure valve 10 is opened, and the cooling liquid in the radiator 8 enters the auxiliary water tank 11 through the pressure valve 10 and the overflow pipe; when the pressure in the radiator 8 is reduced, the cooling liquid in the auxiliary water tank 11 passes through the overflow pipe and the pressure The valve 10 flows back into the radiator 8. In order for the cooling system to work normally, the height of the cooling liquid in the auxiliary wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com