Step type pneumatic digital valve

A digital valve, step-by-step technology, applied in the direction of sliding valves, valve details, safety valves, etc., can solve the problems of high cost, inability to directly realize digital control, complex structure of digital servo valves, etc., achieve low cost, improve external control characteristics, the effect of reducing the magnetic sink phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

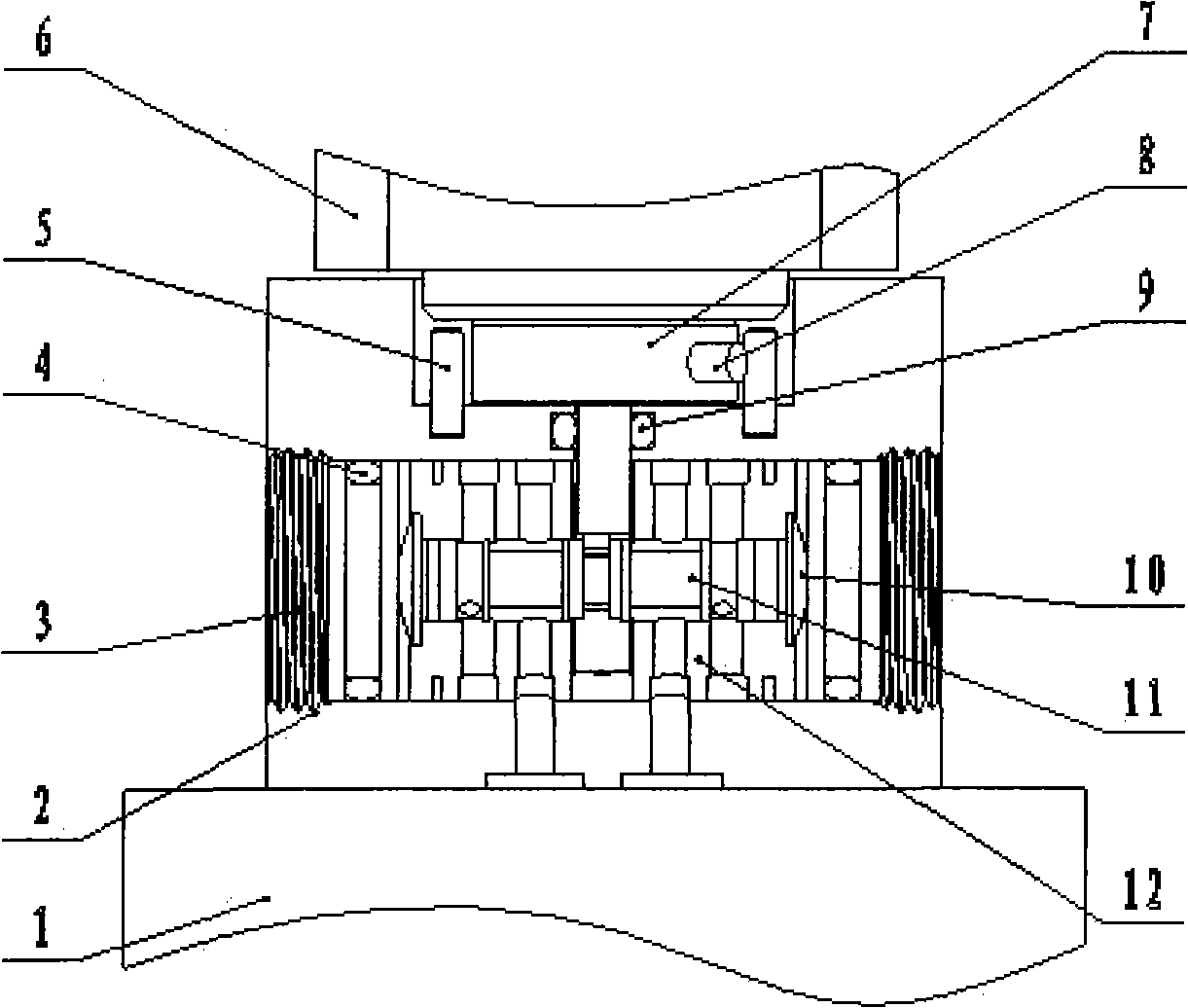

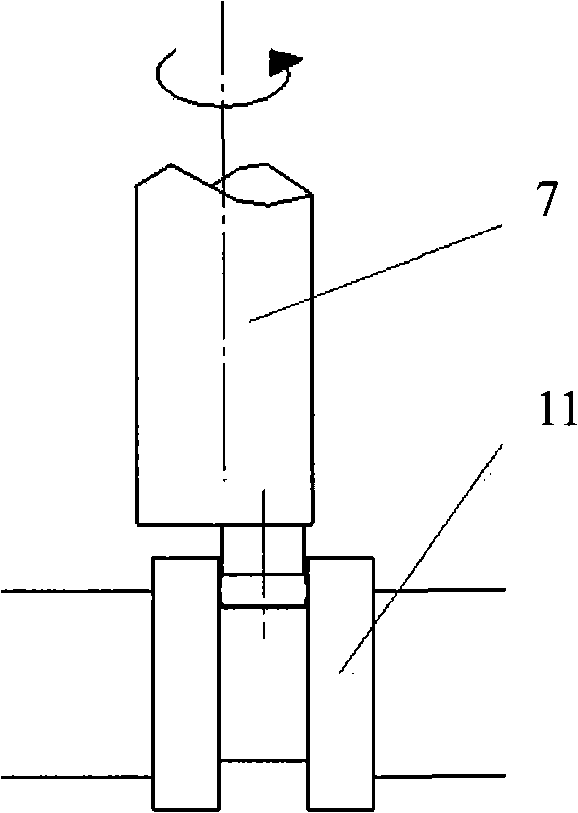

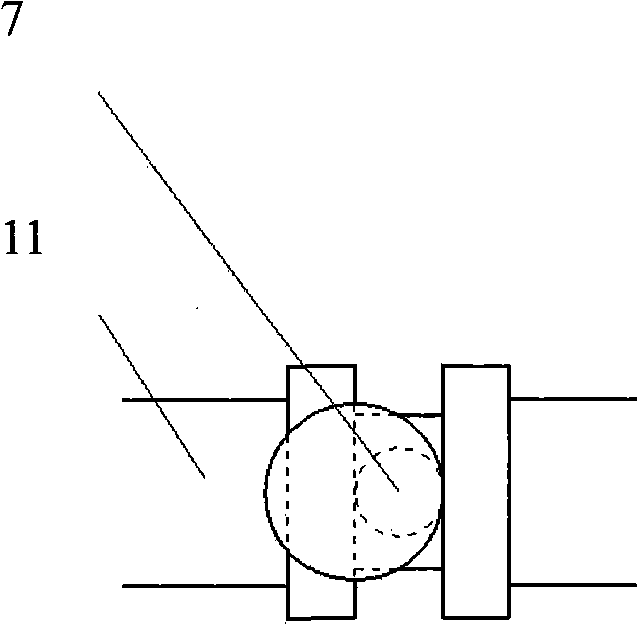

[0023] refer to Figure 1 ~ Figure 4 , a stepping pneumatic digital valve, including a valve seat 2, a valve body and a stepping motor 6, the valve body is located in the valve seat 2, the valve body includes a valve core 11 and a valve sleeve 12, and the valve core 11 can be It is mounted on the valve sleeve 12 to reciprocate left and right, the output shaft of the stepping motor 6 is connected to the input end of the eccentric mechanism 7 , and the output end of the eccentric mechanism 7 is linked with the valve core 11 .

[0024] The eccentric mechanism 7 includes an input shaft and an output shaft eccentric to the center of the input shaft, the output shaft is installed at the lower end of the input shaft, and the output shaft is located between two baffle plates of the valve core 11 .

[0025] The interconnection relationship of valve seat 2, outer end cover 3, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com