Gas sensor

A gas sensor and sensor technology, which is applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of high installation and manufacturing costs, the inability to realize the miniaturization of size and structure, and many parts, so as to reduce the installation and manufacturing costs and avoid laser welding or Hemming process, the effect of fewer parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

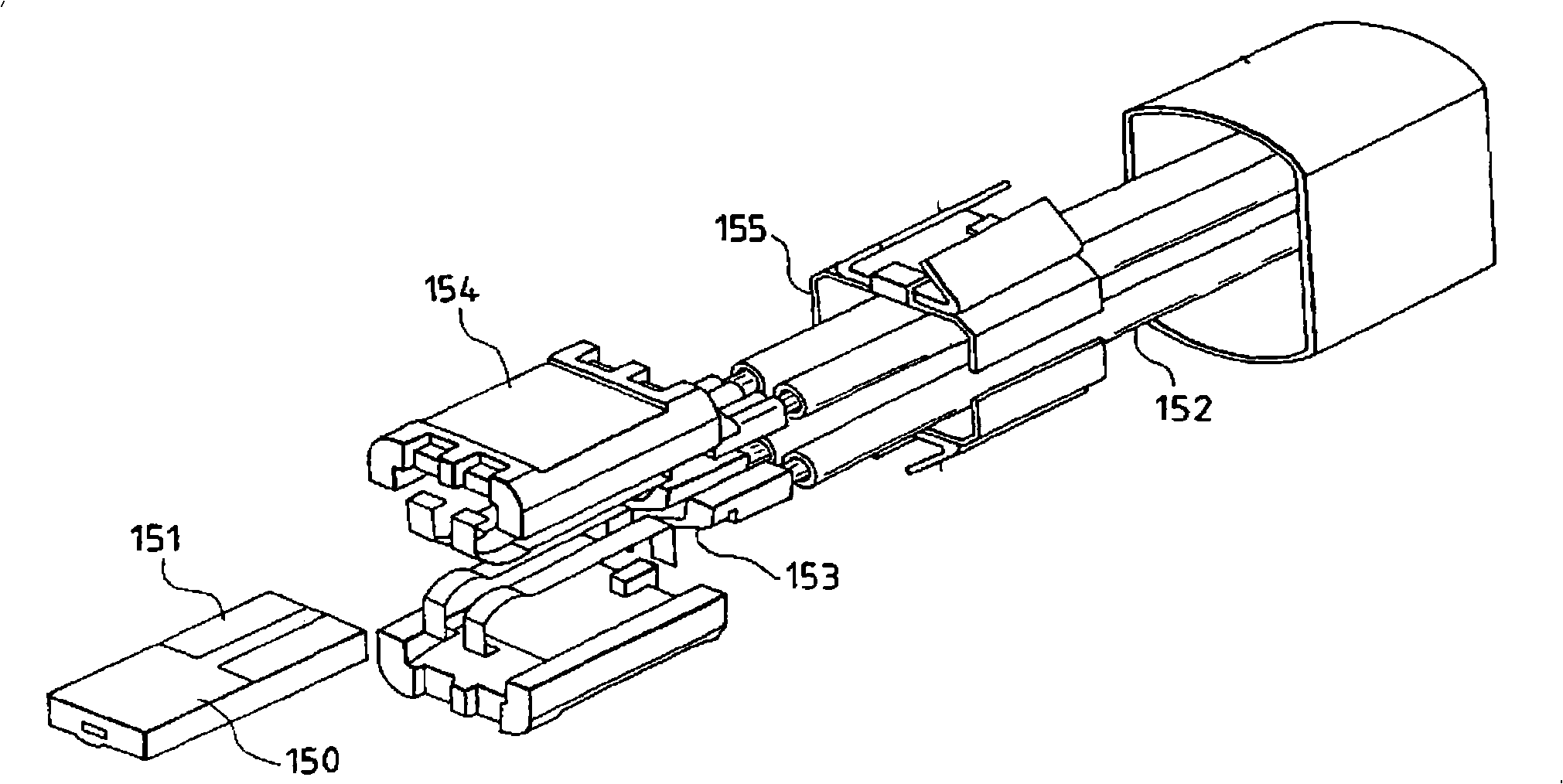

[0031] Such as Figure 8 As shown, the gas sensor of the present invention includes a short sensor 10, a spring clip 20, and a wire harness assembly 30;

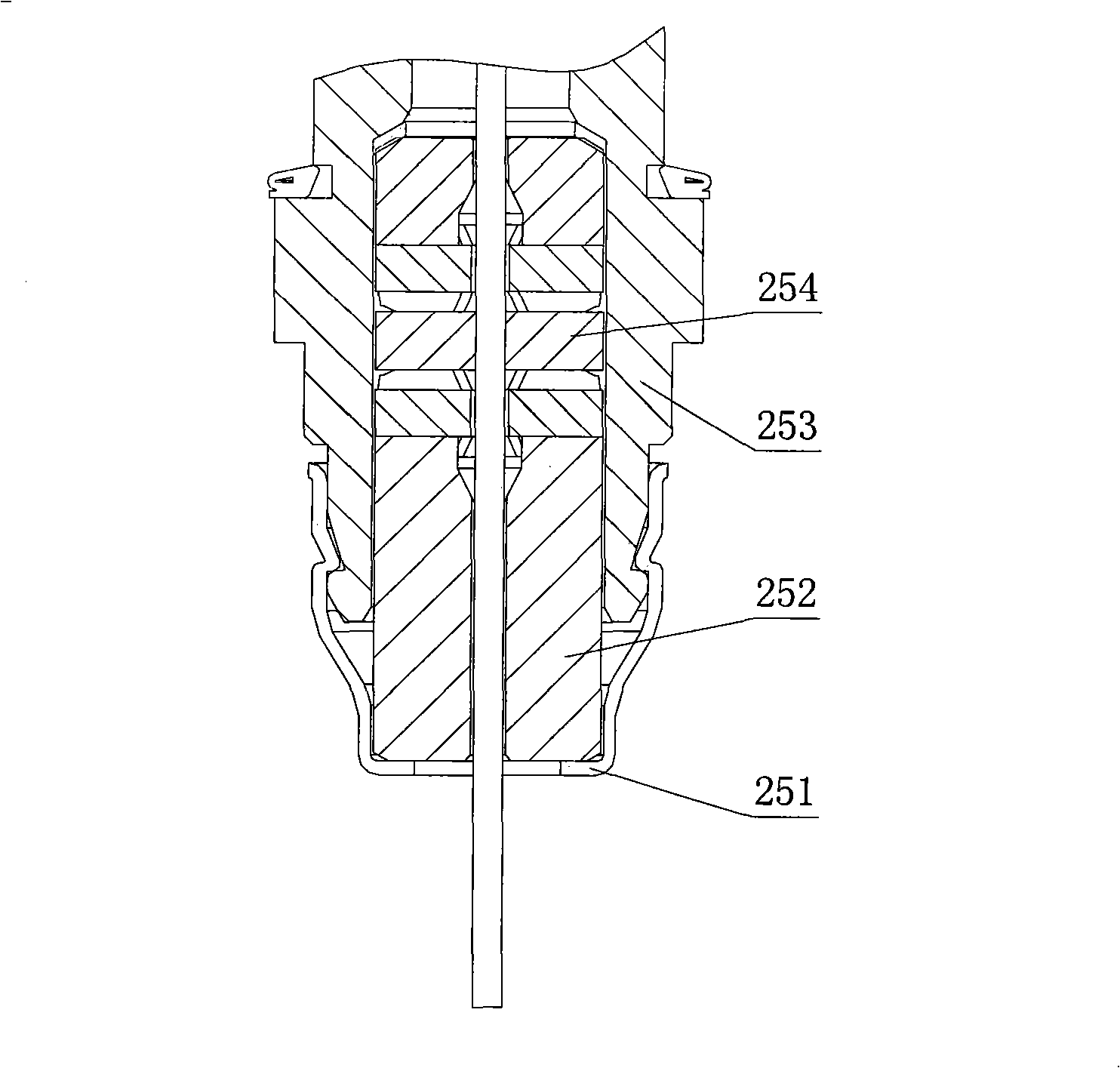

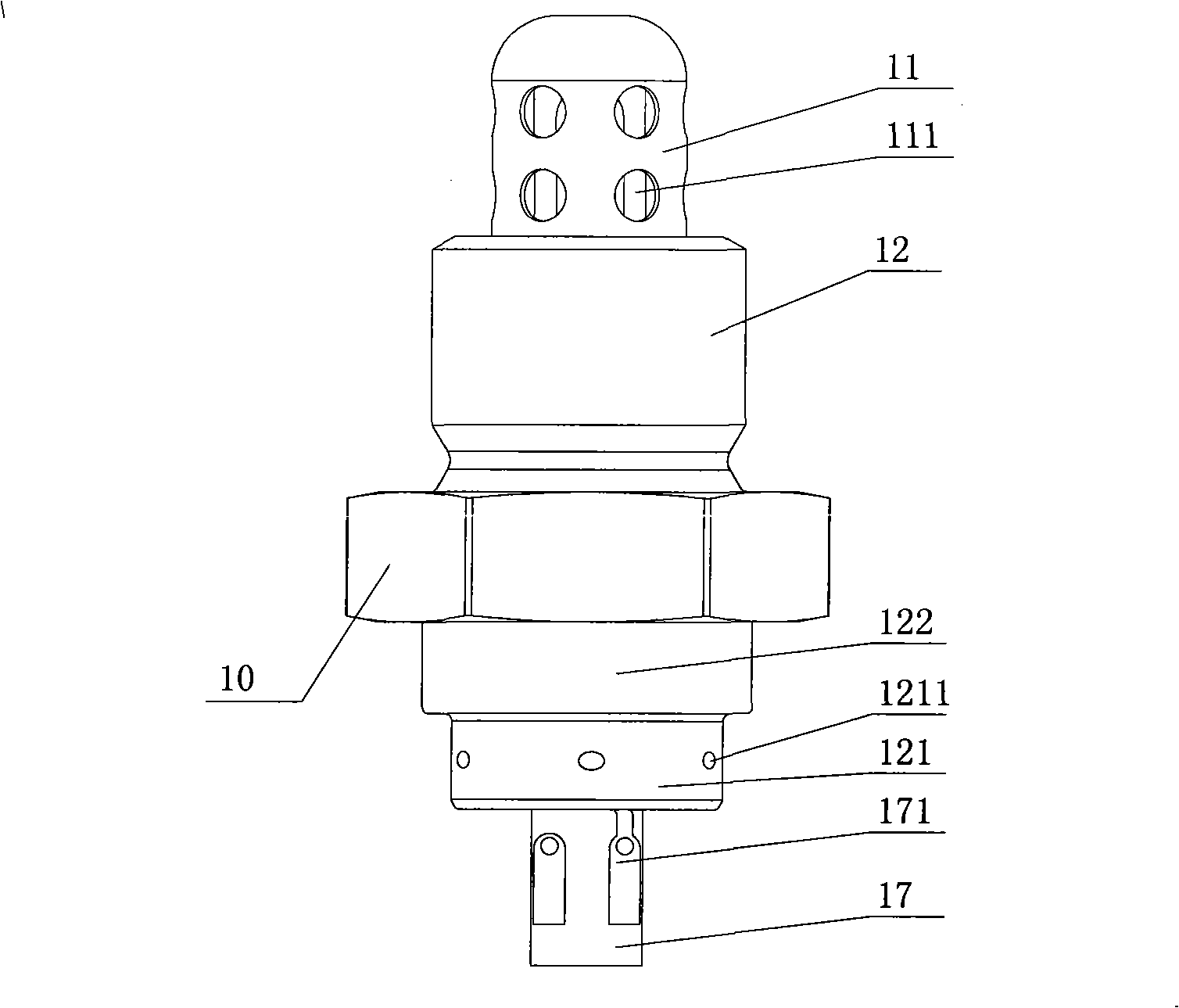

[0032] Such as image 3 , Figure 4 As shown, the short sensor 10 includes a metal protective cover 11, a metal sensor seat 12, an exhaust side bushing 13, a seal 14, a reference side bushing 16, and a ceramic sensing element 17;

[0033] The protective cover 11 includes an extension part 112 , a fixing part 113 , and an umbrella part 114 . The outer diameter of the fixing part 113 is larger than that of the extension part 112 . The outer surface of the fixing part 113 and the inner surface of the top of the sensor seat 12 are interference fit.

[0034] The protective cover 11 is fixed on the top of the sensor base 12 through the fixing portion 113 , the extension 112 of the protection cover 11 protrudes from the top of the sensor base 12 , and the extension 112 is provided with a plurality of through holes 111 . Since th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com