Remelting plating Sn material and electronic component using the same

A technology of electronic components and coatings, which is applied in the field of remelting and plating Sn materials, can solve the problems of reduced solderability, etc., and achieve the effects of low insertion and extraction force, less deterioration of solderability and contact resistance

Active Publication Date: 2008-12-10

JX NIPPON MINING & METALS CO LTD

View PDF2 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, it is also described that if the thickness of the Sn layer is 0.5 μm or less, the solderability will be reduced.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

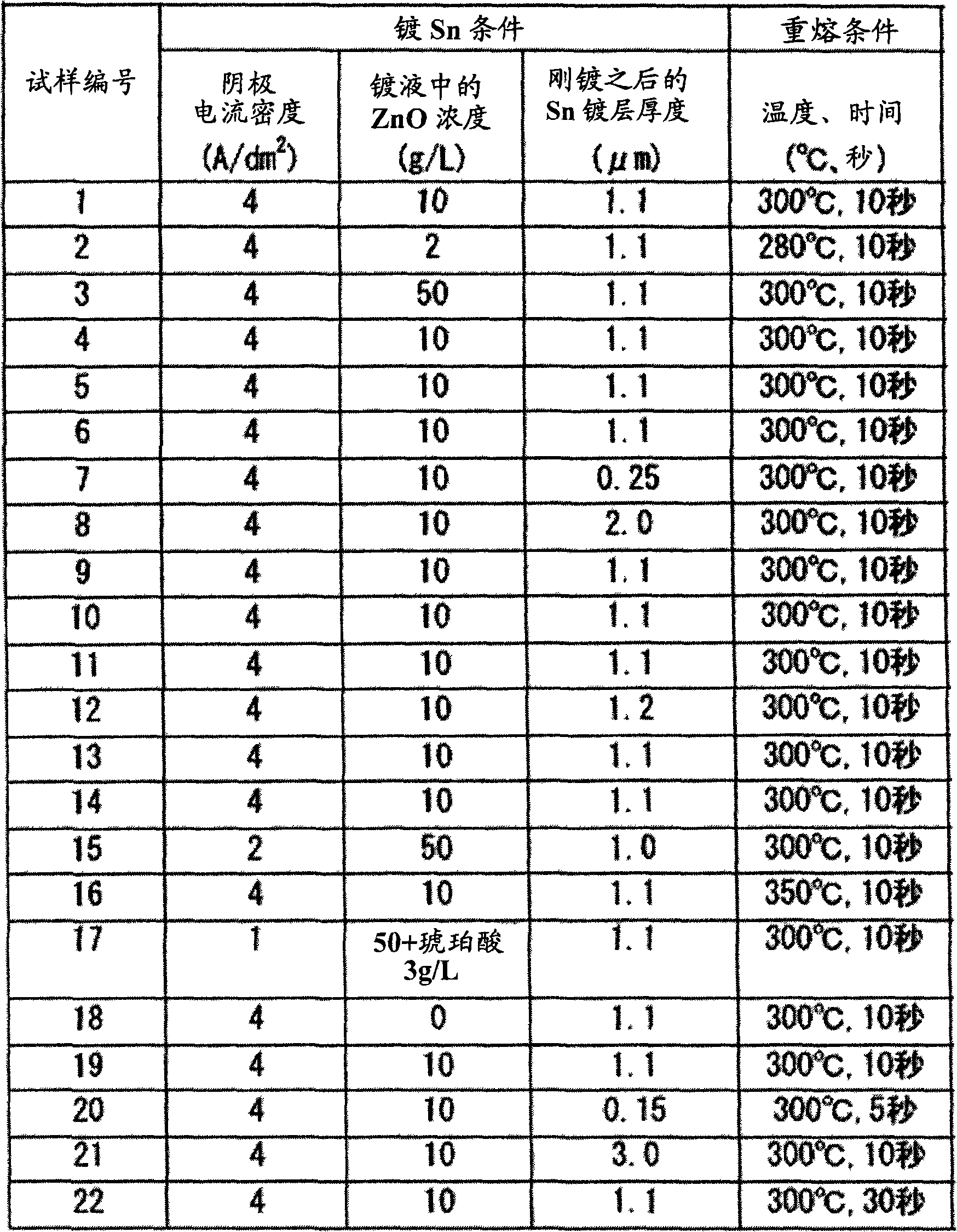

[0067] Examples of the present invention will be described below, but these Examples are for illustrative purposes only and are not intended to limit the present invention.

[0068] 1. Measurement method of each characteristic

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

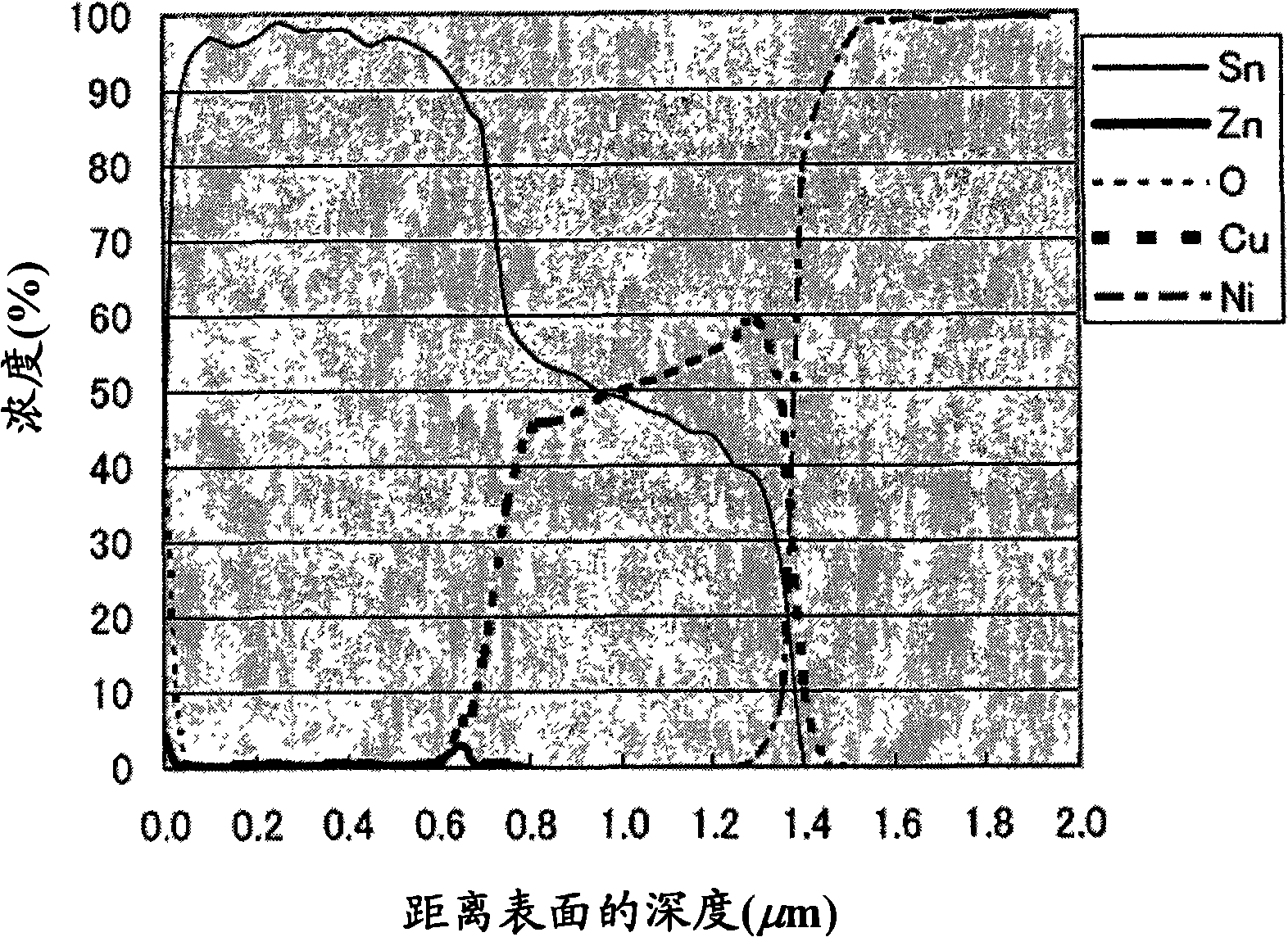

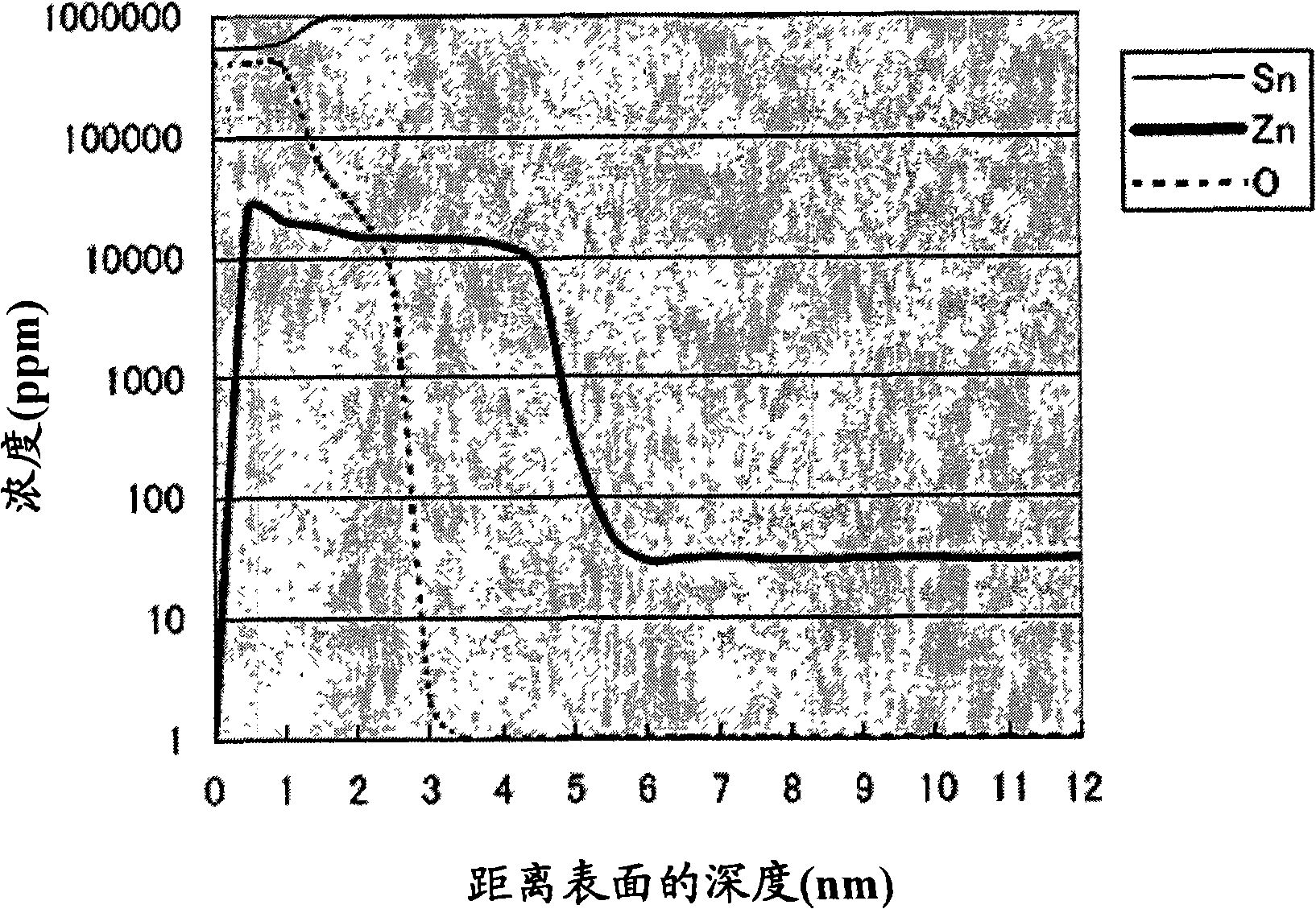

The invention provides a plating Sn material which keeps favorable weldability and low contact resistance even exposed in a high temperature environment and has low plug performance. The plating Sn material is provided with a bottom Ni plating layer, a middle Sn-Cu plating layer and a surface Sn plating layer in sequence on the surface of a copper or a copper alloy, wherein the bottom Ni plating layer is composed of Ni or Ni alloy, the middle Sn-Cu plating layer is composed of an Sn-Cu series alloy with an Sn-Cu-Zn alloy layer at least at one side adjacent to the surface Sn plating layer, and the surface Sn plating layer is composed of Sn alloy with 5-1000 weight ppm of Zn.

Description

technical field [0001] The present invention relates to a remelted Sn material obtained by remelting Sn on the surface of copper or copper alloy. The present invention also relates to electronic components such as connectors, terminals, switches, and lead frames using the plating material. Background technique [0002] Generally, in electronic components such as connectors and terminals used in various electronic equipment such as automobiles, home appliances, and OA equipment, copper or copper alloys are used as base materials to improve their rust resistance, corrosion resistance, and electrical properties. The function is plated. Plating treatments include Au, Ag, Cu, Sn, Ni, solder and Pd, etc., especially Sn-plated materials coated with Sn or Sn alloys. From the perspective of cost, contact reliability and weldability, they are mostly used in connectors, Terminals, switches and outer lead parts of lead frames, etc. [0003] Among Sn-plated materials, remelted Sn-plat...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B32B15/01C23C30/00C23C10/00C23C10/02

Inventor 儿玉笃志田中幸一郎

Owner JX NIPPON MINING & METALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com