Patents

Literature

56 results about "Cu zn alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cu-Zn alloy (or brass) is a very well known material with its gold-like color and malleable structure. It is used in locks, gears, valves, plumbing, musical instruments, decorative structures etc….

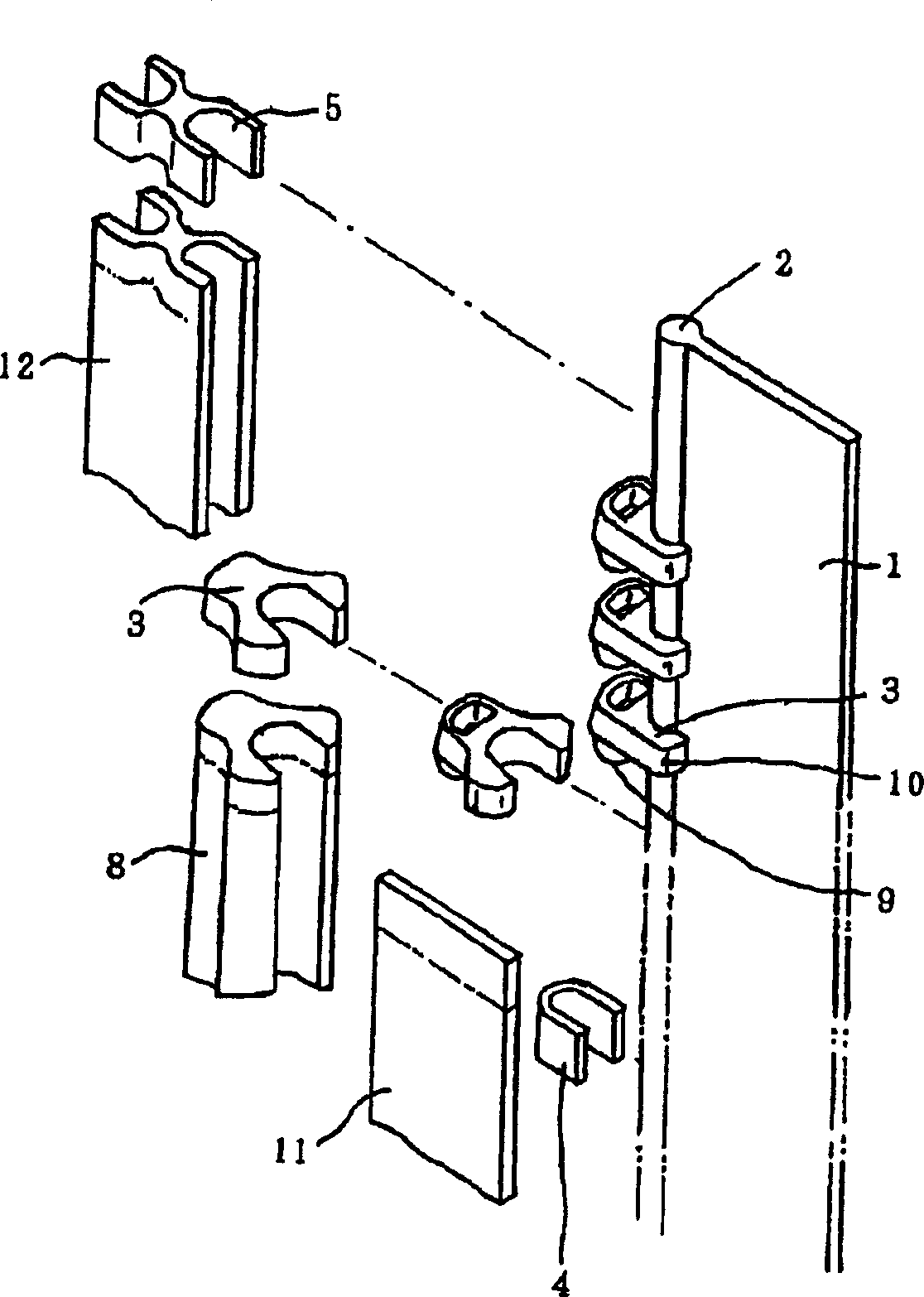

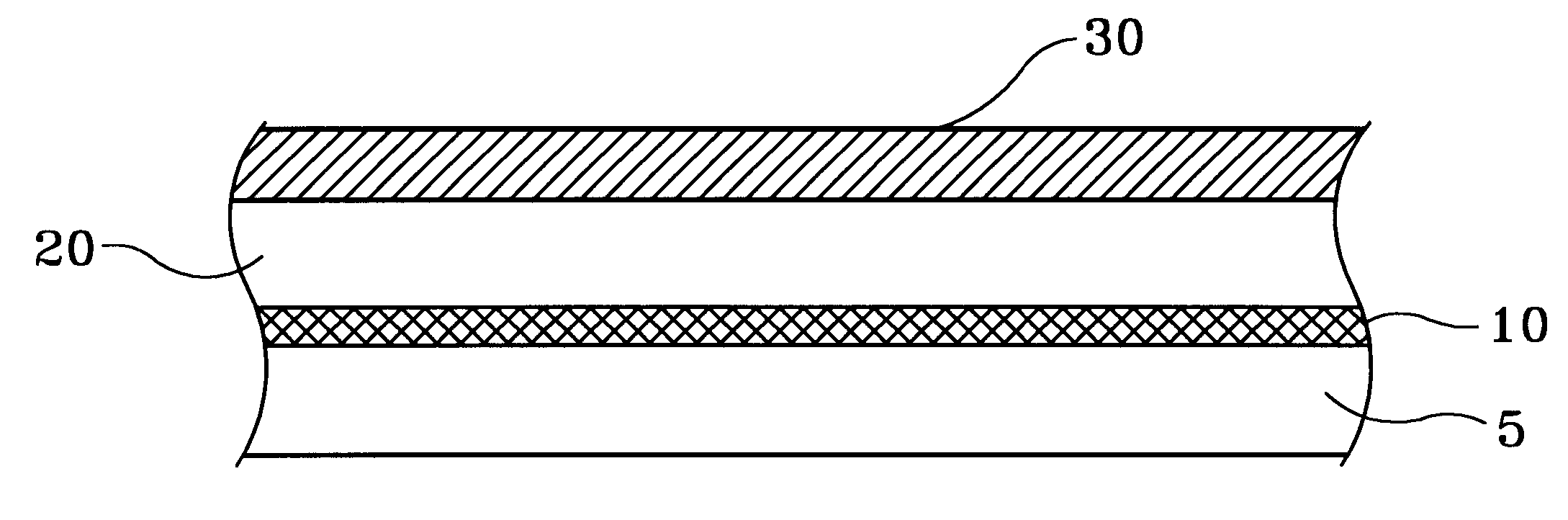

Method of reducing electromigration in a copper line by electroplating an interim copper-zinc alloy thin film on a copper surface and a semiconductor device thereby formed

InactiveUS6660633B1Improves Cu interconnect reliabilityReduce manufacturing costElectrolysis componentsSolid-state devicesCopper interconnectChemical solution

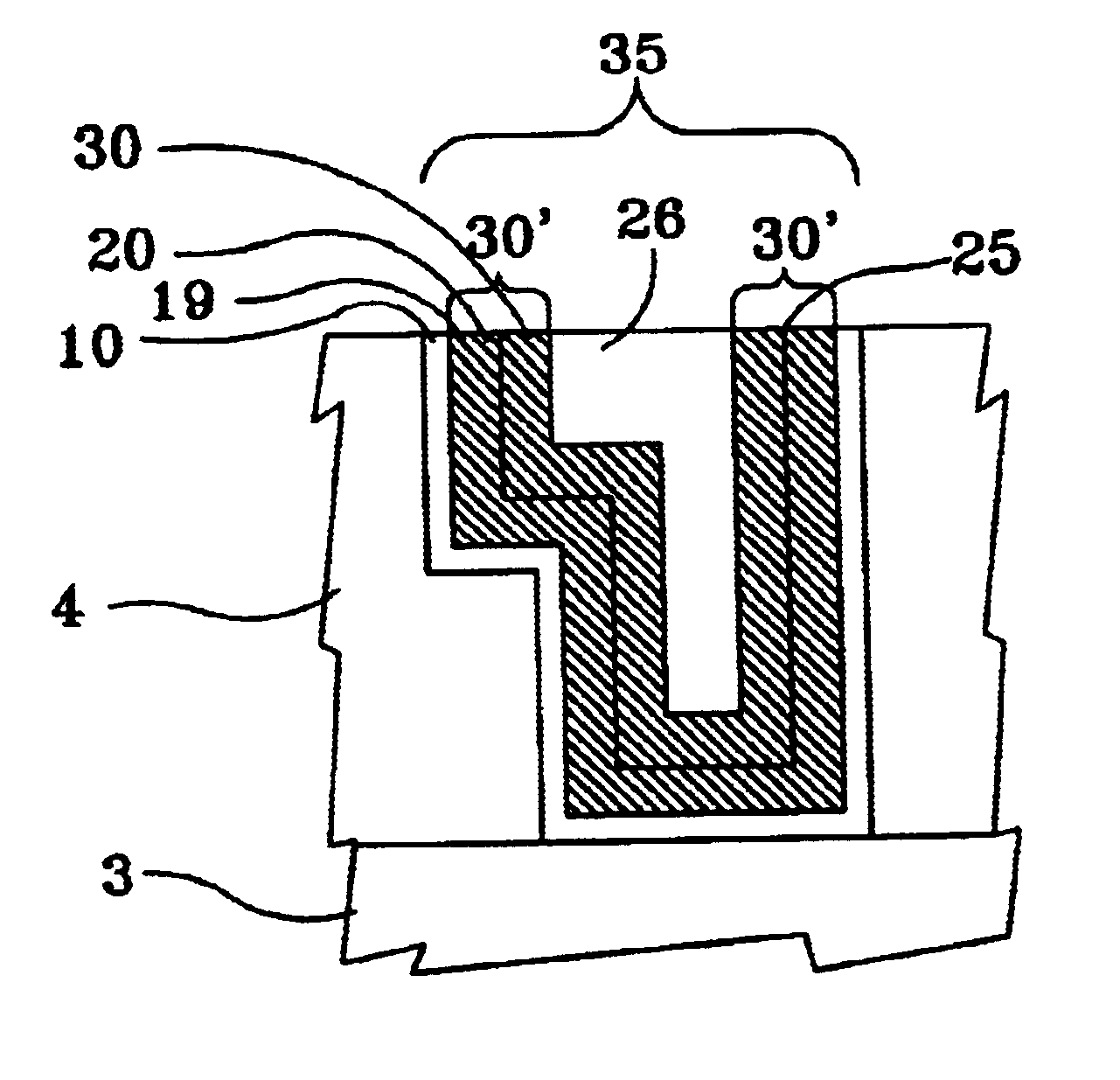

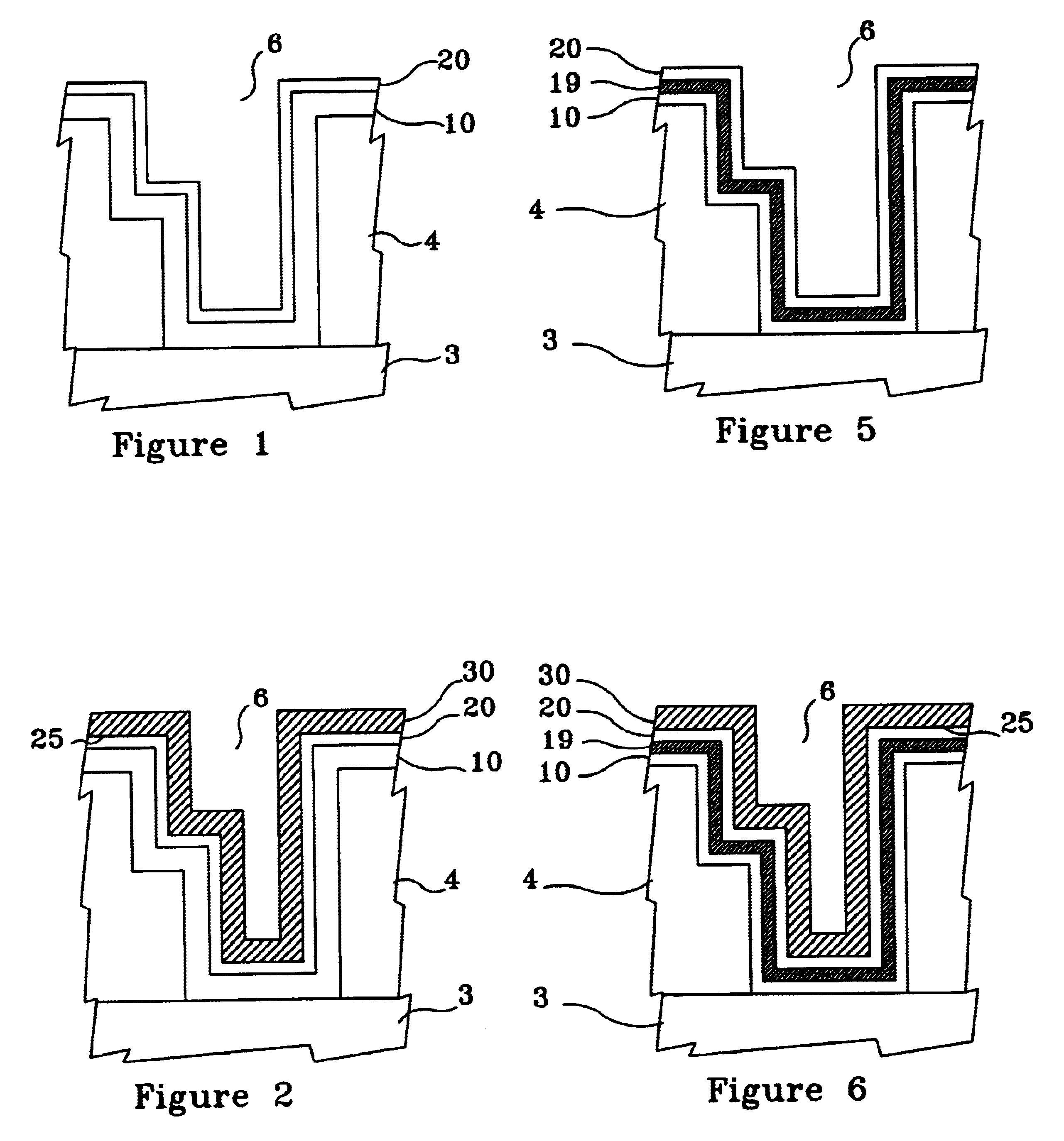

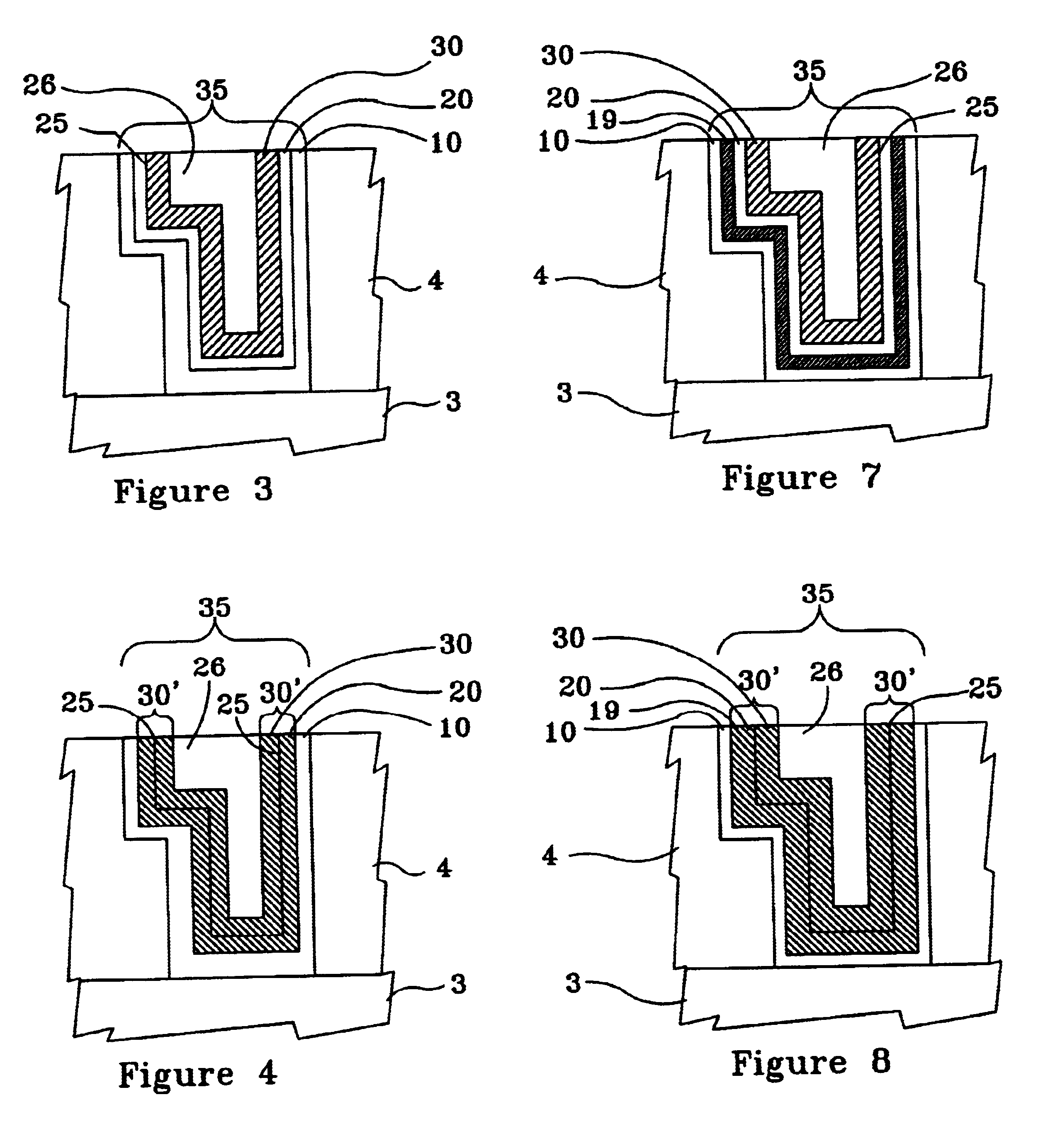

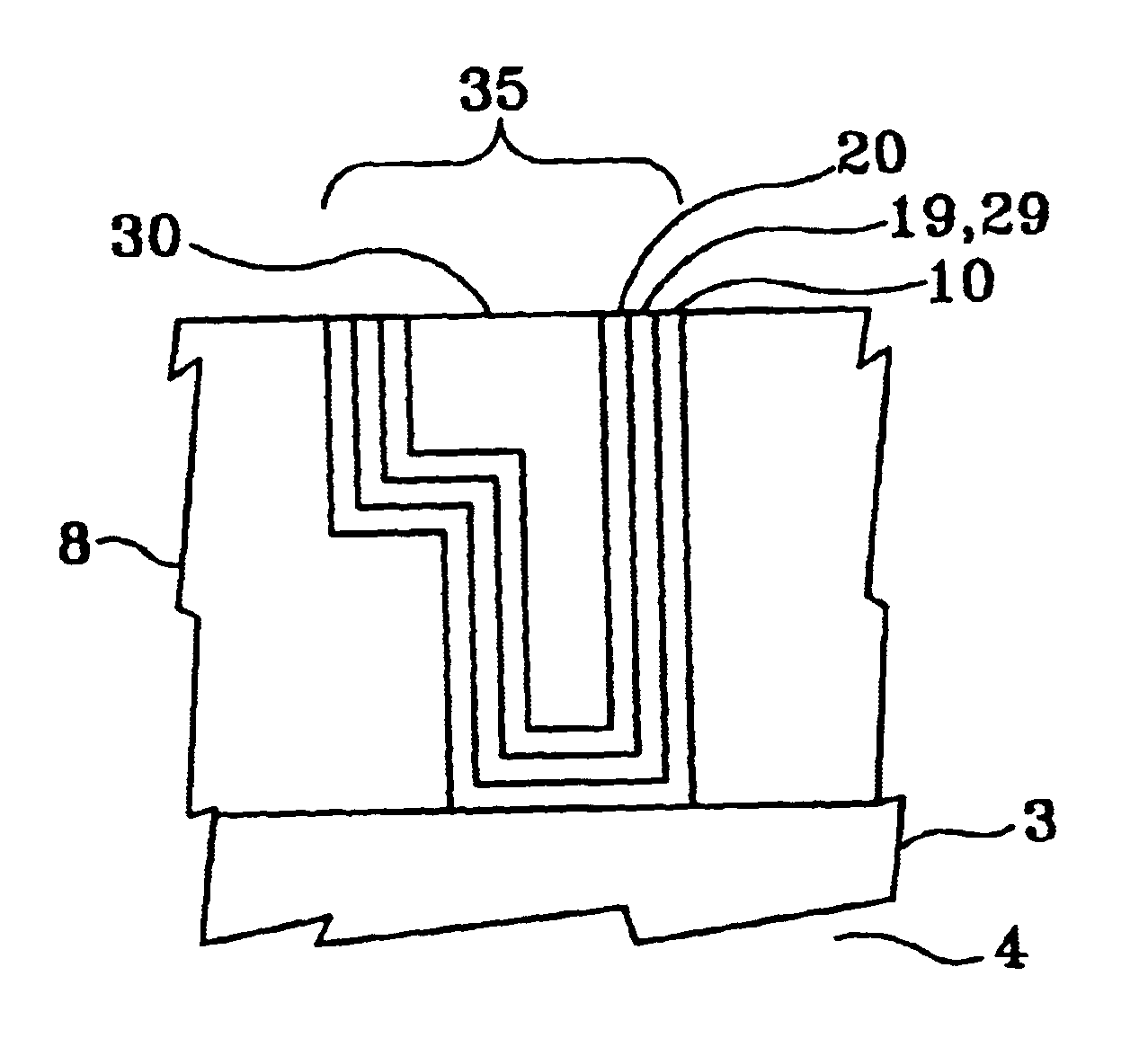

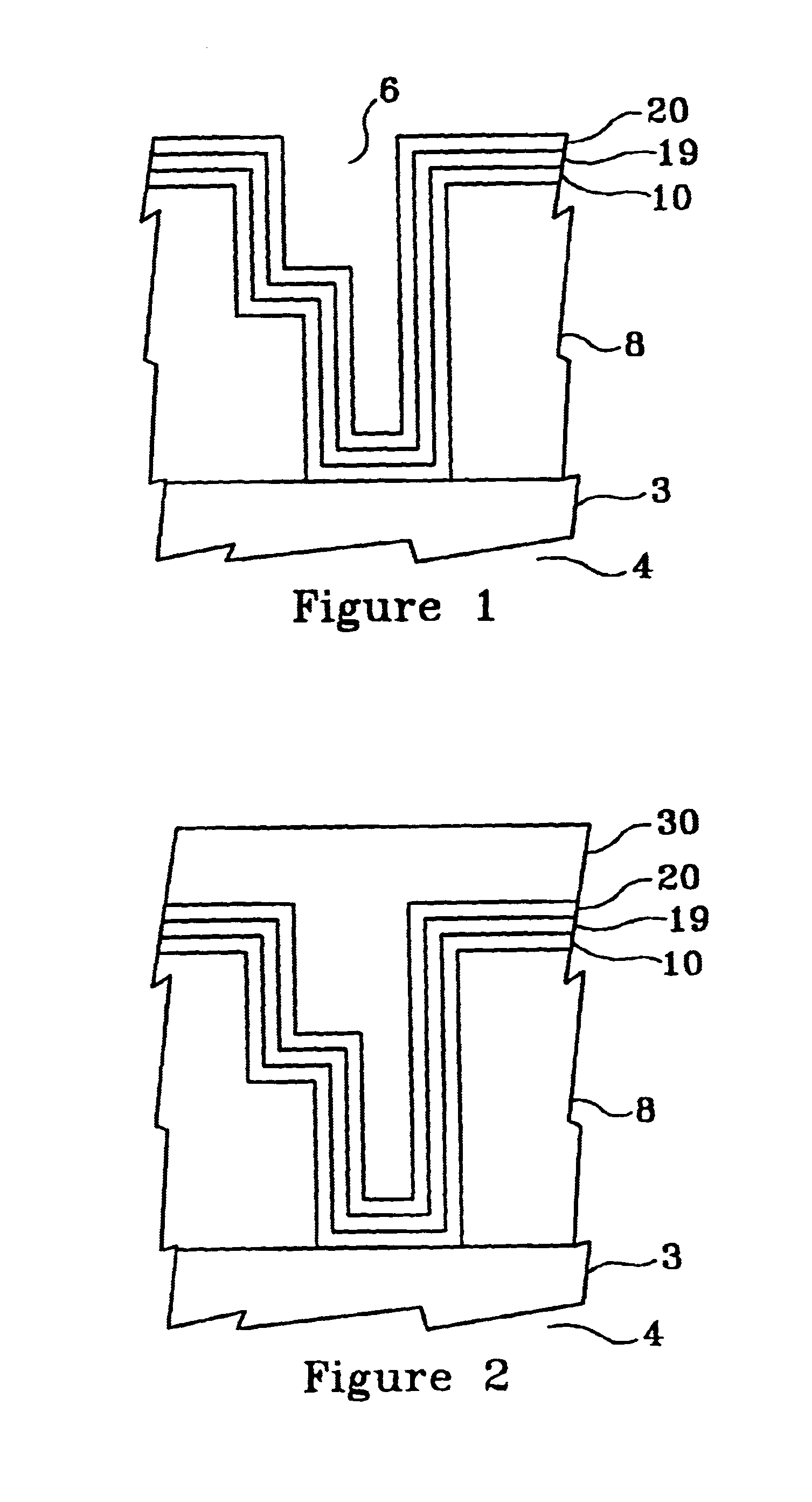

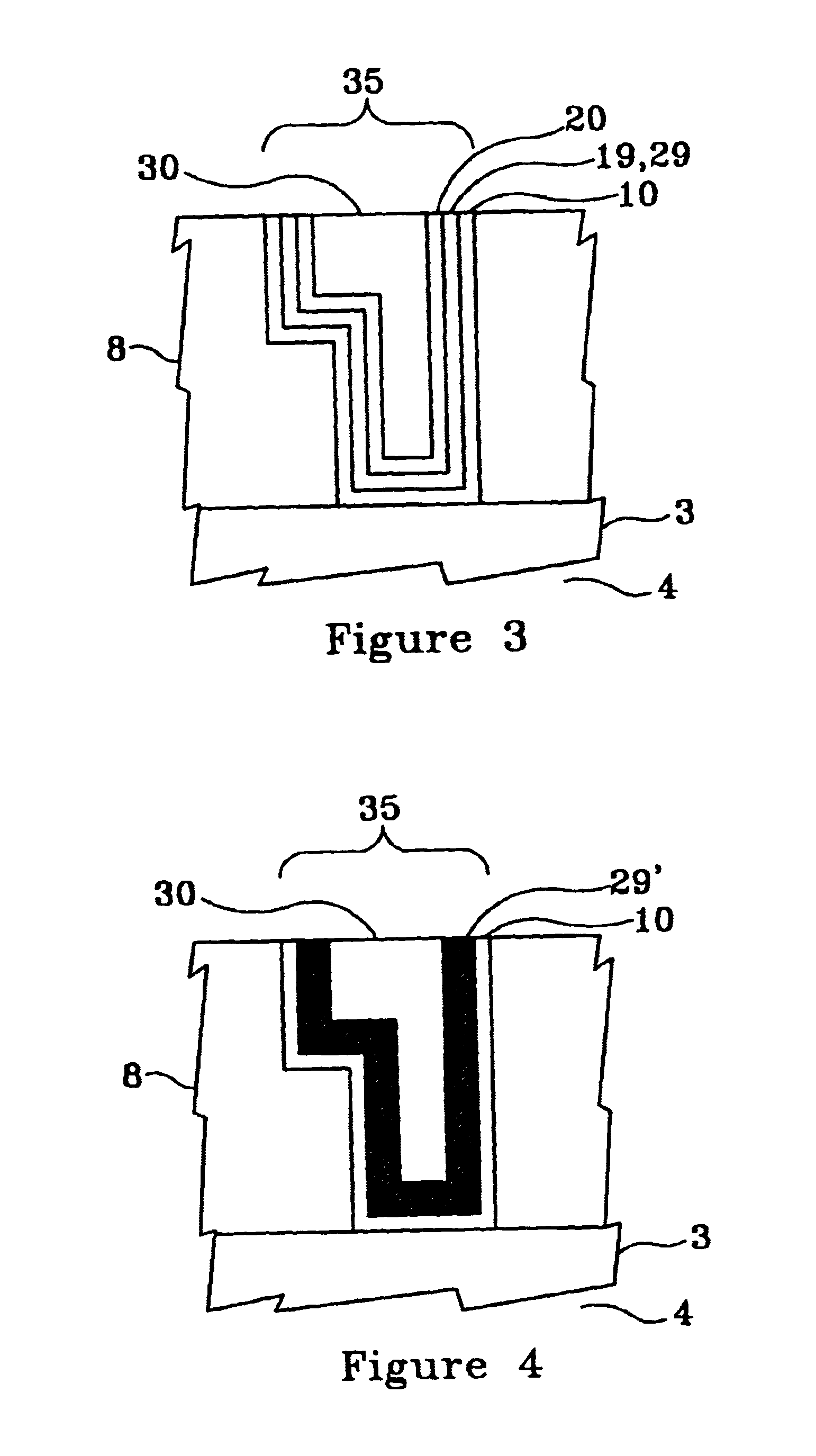

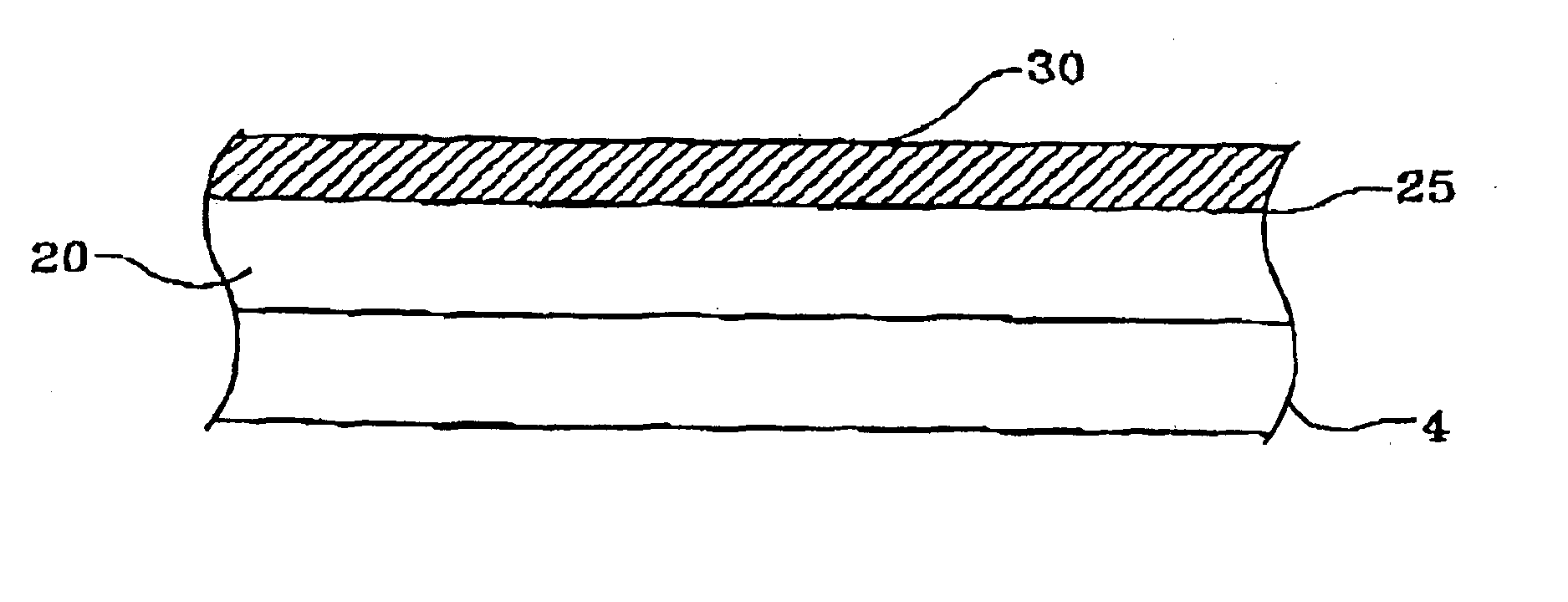

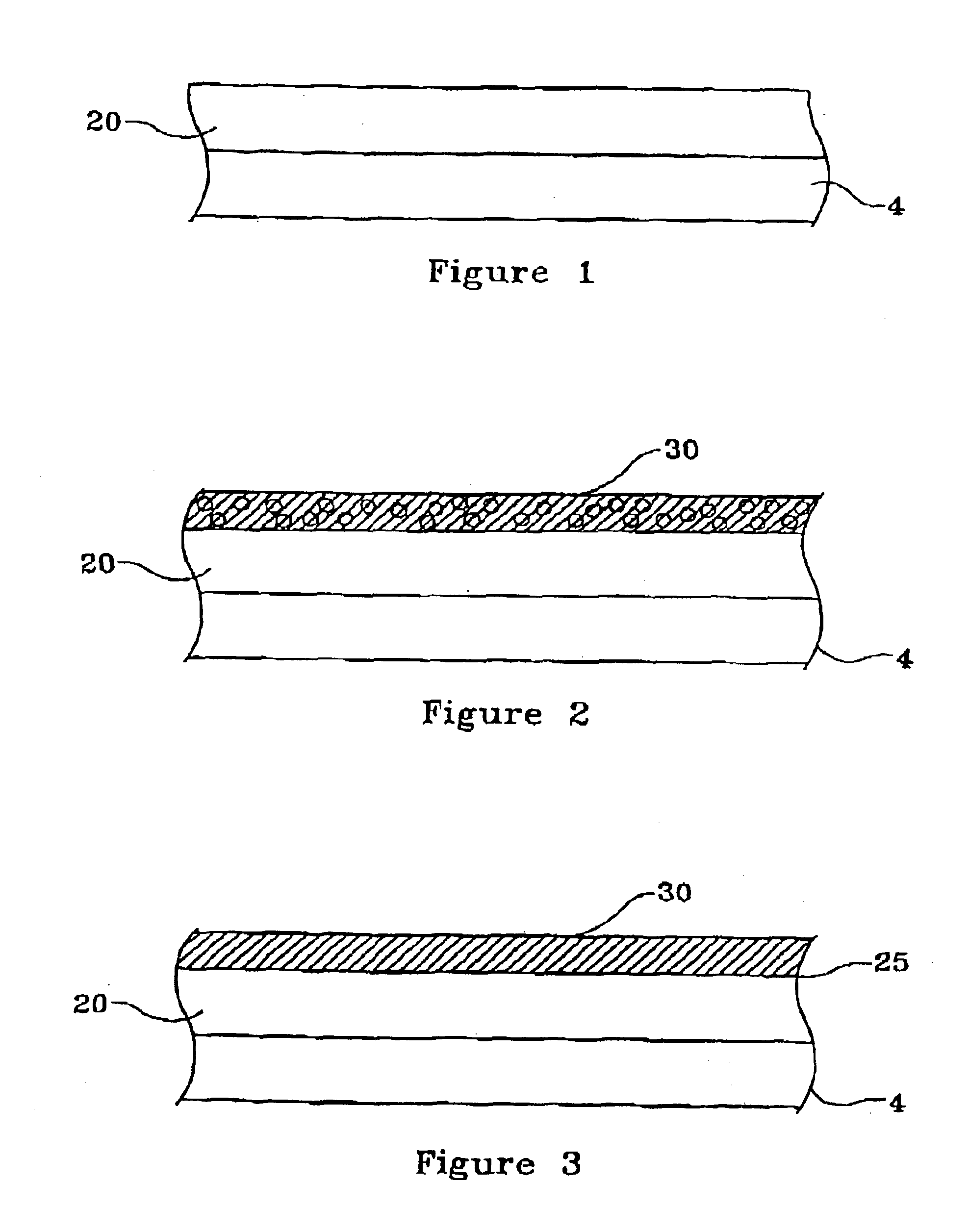

A method of fabricating a semiconductor device, having an interim reduced-oxygen Cu-Zn alloy thin film (30) electroplated on a blanket Cu surface (20) disposed in a via (6) by electroplating, using an electroplating apparatus, the Cu surface (20) in a unique chemical solution containing salts of Zn and Cu, their complexing agents, a pH adjuster, and surfactants; and annealing the interim electroplated Cu-Zn alloy thin film (30); filling the via (6) with further Cu (26); annealing and planarizing the interconnect structure (35); and a semiconductor device thereby formed. The reduction of electromigration in copper interconnect lines (35) is achieved by decreasing the drift velocity in the copper line (35) / via (6), thereby decreasing the copper migration rate as well as the void formation rate, by using an interim conformal Cu-rich Cu-Zn alloy thin film (30) electroplated on a Cu surface (20) from a stable chemical solution, and by controlling the Zn-doping thereof, which improves also interconnect reliability and corrosion resistance.

Owner:GLOBALFOUNDRIES US INC

Preparation method of nano porous copper capable of being patterned

The invention discloses a preparation method of nano porous copper capable of being patterned, comprising the following steps: (1), sputtering a Cr-Cu seed layer on a sheet glass, spin coating positive photo-resist, baking the photo-resist, exposing, and developing in turn, so as to pattern the nano porous copper photo-resist; (2), depositing a copper stress buffer layer and a Cu-Zn alloy layer by the electro-deposition technique, to obtain a patterned precursor alloy thin film; and (3), performing de-alloying treatment on the patterned Cu-Zn patterned precursor alloy thin film in an acidic solution, removing the positive photo-resist, finally implementing the patterned nano porous copper so as to obtain a nano porous copper array. The preparation method and the micro-processing technique are compatible; specifically, the nano porous copper arrays with various patterns are obtained by the photo resist patterning technique, the Cu-Zn alloy co-deposition technique, and the de-alloying technique; the preparation method has the advantages of simple process, low cost, easy control, and good compatibility to the micro-processing technique.

Owner:SHANGHAI JIAO TONG UNIV

Cu-zn system alloy with good of durable crack resistant performance and manufacturing method thereof

Provided is a Cu-Zn alloy which has a high Zn content, can be cold-worked, and has high strength and superior season cracking resistance. A cold-worked Cu-Zn alloy containing at least 10% Zn is subjected to at least one treatment selected among shot peening, shot blasting, sand blasting, and steel ball shot blasting; thus, the tensile residual stress on the surface of the alloy is reduced or brought into the state of compressive residual stress. The Cu-Zn alloy has a composition expressed by the general formula: CuaZnbXc (wherein X is at least one element selected among Al, Si, Sn, and Mn; and, by mass%, a is the balance, 10 C22C 9 / 04 C22F 1 / 08 2 10 1 2003 / 12 / 9 1542150 2004 / 11 / 3 1250757 2006 / 4 / 12 2006 / 4 / 12 2006 / 4 / 12 YKK Corp. Japan Koizumi Takuya Yoshimura Taiji Kita Kazuhiko he tengyun 11038 The Patent Agency of the Chinese Council for the Promotion of International Trade (CCPIT) No.1 Waidajie, Fuxingmen, Beijing 100086 Japan 2003 / 5 / 1 126292 / 2003

Owner:YKK CORP

High manganese easy cutting copper zinc alloy

The present invention relates to one kind of free machining high manganese Cu-Zn alloy, which consists of Cu 45- 70 wt%, Mn 7-30 wt%, Pb 0.2-4 wt%, X 0.0001-2 wt%, and Zn and inevitable impurity for the rest; where, X is at least one of elements Fe, As, P, B, Cr, Li, Ni, Sn, Al. The free machining high manganese Cu-Zn alloy has free machining performance similar to that of lead brass, lowered material cost and excellent plastic working performance, and may be used in producing plastic worked product and cast product.

Owner:NINGBO POWERWAY ALLOY MATERIAL

Method of reducing electromigration by forming an electroplated copper-zinc interconnect and a semiconductor device thereby formed

InactiveUS6717236B1Reduce electromigrationImprove corrosion resistanceTransistorElectrolysis componentsCopper interconnectChemical solution

A method of reducing electromigration in a dual-inlaid copper interconnect line (3) by filling a via (6) with a Cu-rich Cu-Zn alloy (30) electroplated on a Cu surface (200 from a stable chemical solution, and by controlling the Zn-doping thereof, which also improves interconnect reliability and corrosion resistance, and a semiconductor device thereby formed. The method involves using a reduced-oxygen Cu-Zn alloy as fill (30) for the via (6) in forming the dual-inlaid interconnect structure (35). The alloy fill (30) is formed by electroplating the Cu surface (20) in a unique chemical solution containing salts of Zn and Cu, their complexing agents, a pH adjuster, and surfactants, thereby electroplating the fill (30) on the Cu surface (20); and annealing the electroplated Cu-Zn alloy fill (30); and planarizing the Cu-Zn alloy fill (30), thereby forming the dual-inlaid copper interconnect line (35).

Owner:GLOBALFOUNDRIES US INC

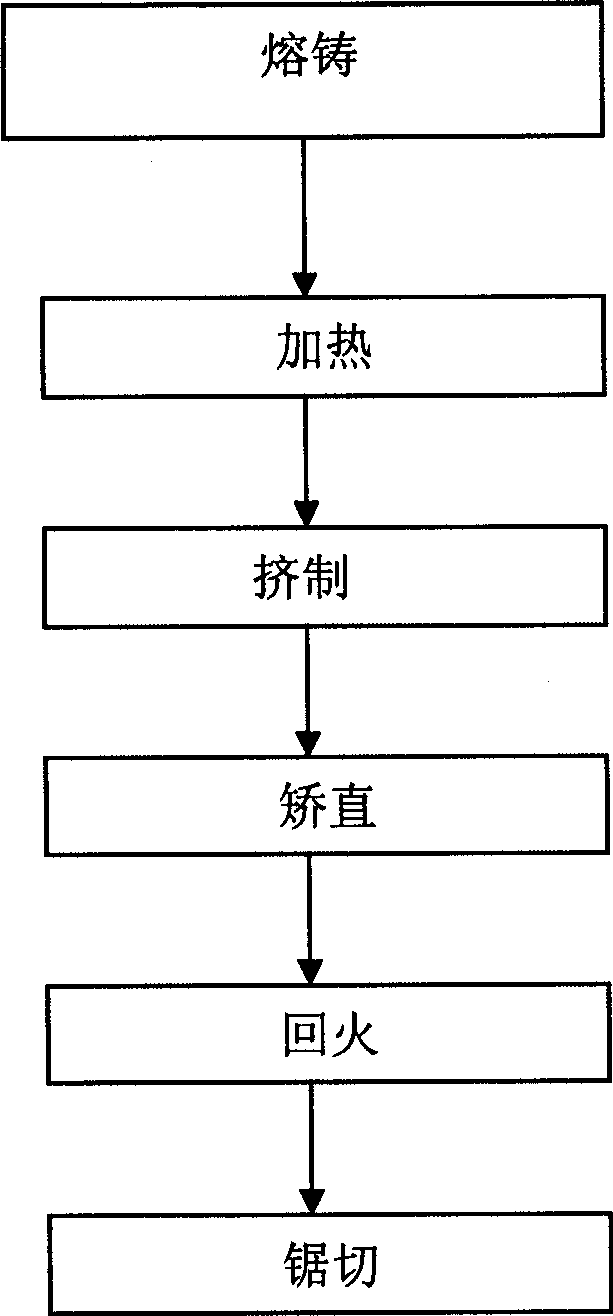

Method for preparing high-strength wear-resistant brass pipe

InactiveCN1710127AAdapt to the needs of the automotive industryImprove product qualityWear resistantBeta phase

The invention discloses a preparation technique of a brass tube of high rigidity and strong abrade resistance which is based on a new single beta phase based high rigidity and strong abrade resistance brass material adopting heat pressing technique with a 95 percent maximum deformation. It is based on Cu-Zn alloy together with metal elements which forms abrade resistance phase automatically such as Fe, Ni, Mn, Co, Ti, Cr, Si, Al, forming complex 5 to 9 plurality alloy system; these alloy element of strong combining ability hardly reacts with basal elements Cu and Zn though combines vividly with each other producing high rigidity compounds such as FeAl3, Mn5Si, Ni2Si, Co2Si, Cr-Si, Fe3Si, Ni-Ti and forming abrading resistant phase of complex elements and remarkably high rigidity.

Owner:LUOYANG COPPER PROCESSING GROUP

Silver-based solder paste and preparation method thereof

InactiveCN106181117ASimple production processImprove efficiencyWelding/cutting media/materialsSoldering mediaPowder mixtureAlkylphenol

The invention discloses silver-based solder paste and a preparation method thereof. The silver-based solder paste comprises the components of, by mass, 75%-80% of Ag-Cu-Zn alloy brazing filler metal powder, 10%-14% of fluoride silver brazing flux powder, 7%-8% of a saturated sodium silicate aqueous solution, 2%-3% of white oil and 1%-2% of alkylphenol polyoxyethylene. The preparation method comprises the steps that (1) an Ag-based brazing filler metal ingot is made into powder of about 200 meshes, 75%-80% of the filler metal powder and 10%-14% of the fluoride silver brazing flux powder are selected by mass and stirred to be evenly mixed by utilization of a glass rod; (2) sodium silicate powder with the modulus being 1.8-2.0 is dissolved into distilled water at the temperature of around 80 DEG C, the saturated sodium silicate solution is prepared, and 7%-8% of the saturated sodium silicate solution is weighed; (3) 2%-3% of the white oil is sufficiently dissolved into 1%-2% of the alkylphenol polyoxyethylene, and an organic solution is obtained after evenly mixing the white oil and the alkylphenol polyoxyethylene; and (4) a brazing filler metal and fluoride silver brazing flux powder mixture and the saturated sodium silicate solution are evenly mixed, and the organic solution is added into a mixture and mixed evenly again to obtain the solder paste.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Welding method of electric contact

InactiveCN104289781AEasy to operateQuality improvementSoldering apparatusMetal working apparatusFiller metalHeating temperature

The invention discloses a welding method of an electric contact and belongs to the technical field of electronic production. The method comprises the following steps that (1) welding materials are prepared first, wherein a circular electric contact with the specification of 7 mm * 5 mm is selected, the materials are AgW50, red copper is T2, the specification is a circle of 10 mm * 5 mm, and brazing materials are Ag-Cu-Zn alloy; (2) brazing equipment is prepared; and (3) resistance brazing equipment is used, the contact, the red copper and brazing filler metal are placed in order, brazing flux is arranged on the surface of the brazing filler metal in a coating mode, welding current is adjusted to be 65 A-75 A, manual pressurizing is used, electrifying and heating are carried out, when the red copper becomes red, welding flux is molten and is evenly effused to the periphery, electrifying is stopped, cooling is carried out until the welding flux is solidified, and a welding piece is taken out. A resistance brazing method is used for carrying out welding on the AgW50 contact materials and the red copper, the heating temperature and the heating time of resistance brazing can be controlled easily, an obtained brazing connector is high in quality, the problems that a flame brazing AgW50-Cu contact is low in efficiency and unstable in quality are well solved, and the electric contact is easy to operate and convenient to promote and use.

Owner:XIAN SANWEI SECURITY TECH

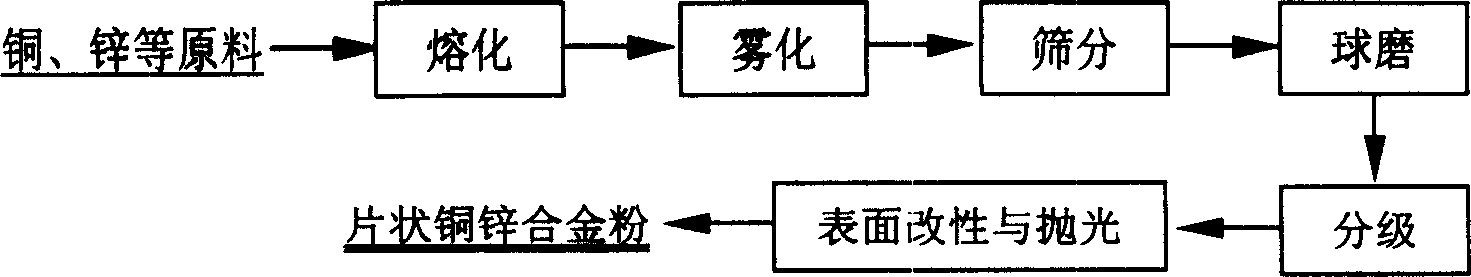

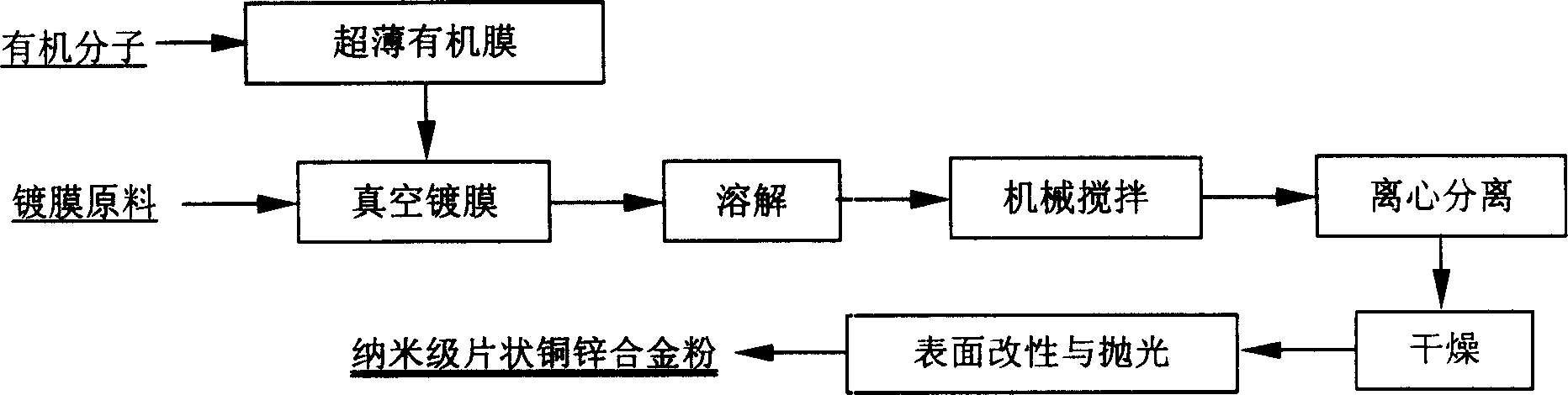

Nano level sheet copper zinc alloy powder and its producing method

InactiveCN1616694AUniform particle thicknessThe particle surface is flat and smoothOrganic filmComposite substrate

The nanometer level sheet Cu-Zn alloy powder contains Cu 68-93 wt%, Zn 6-30 wt% and Al 0.2-1.6 wt%. The nanometer level sheet Cu-Zn alloy powder is produced through depositing Cu, Zn and other elements onto superthin organic film continuously through film coating process; eliminating the organic film with solvent; crushing into nanometer level; drying; coating to denature and polishing. The present invention adopts slowly shifted composite substrate comprising soluble superthin organic film and flexible base, and the deposited atoms move along the superthin organic film and coagulate onto the stable and metastable position on the organic film to form compact and smooth nanometer film. The nanometer level sheet Cu-Zn alloy powder of the present invention has homogeneous grain thickness of 30-100 nm, leveled and smooth surface, grain size of 0.1-3 micron and diameter / thickness ratio of 30-900.

Owner:CENT SOUTH UNIV

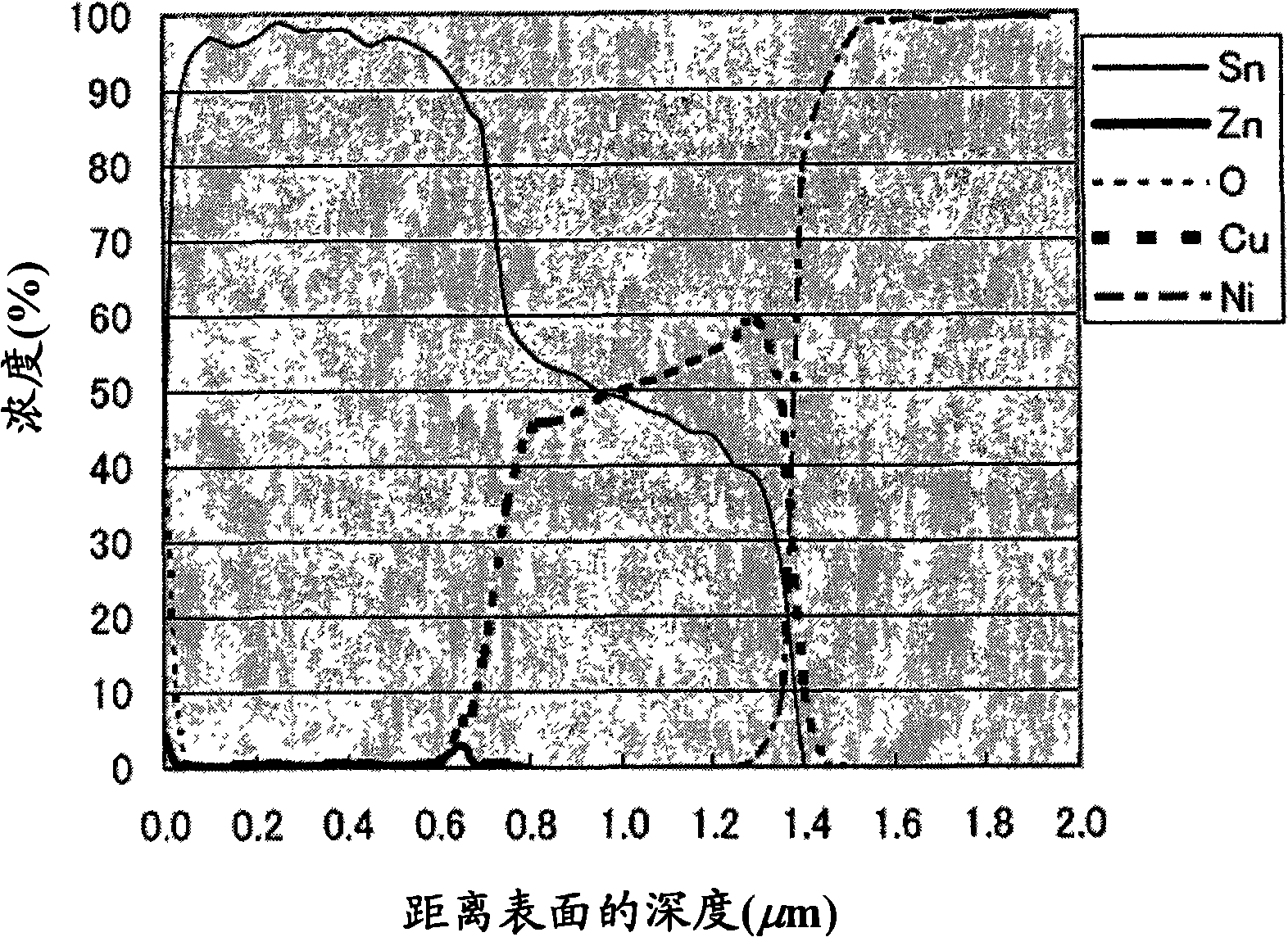

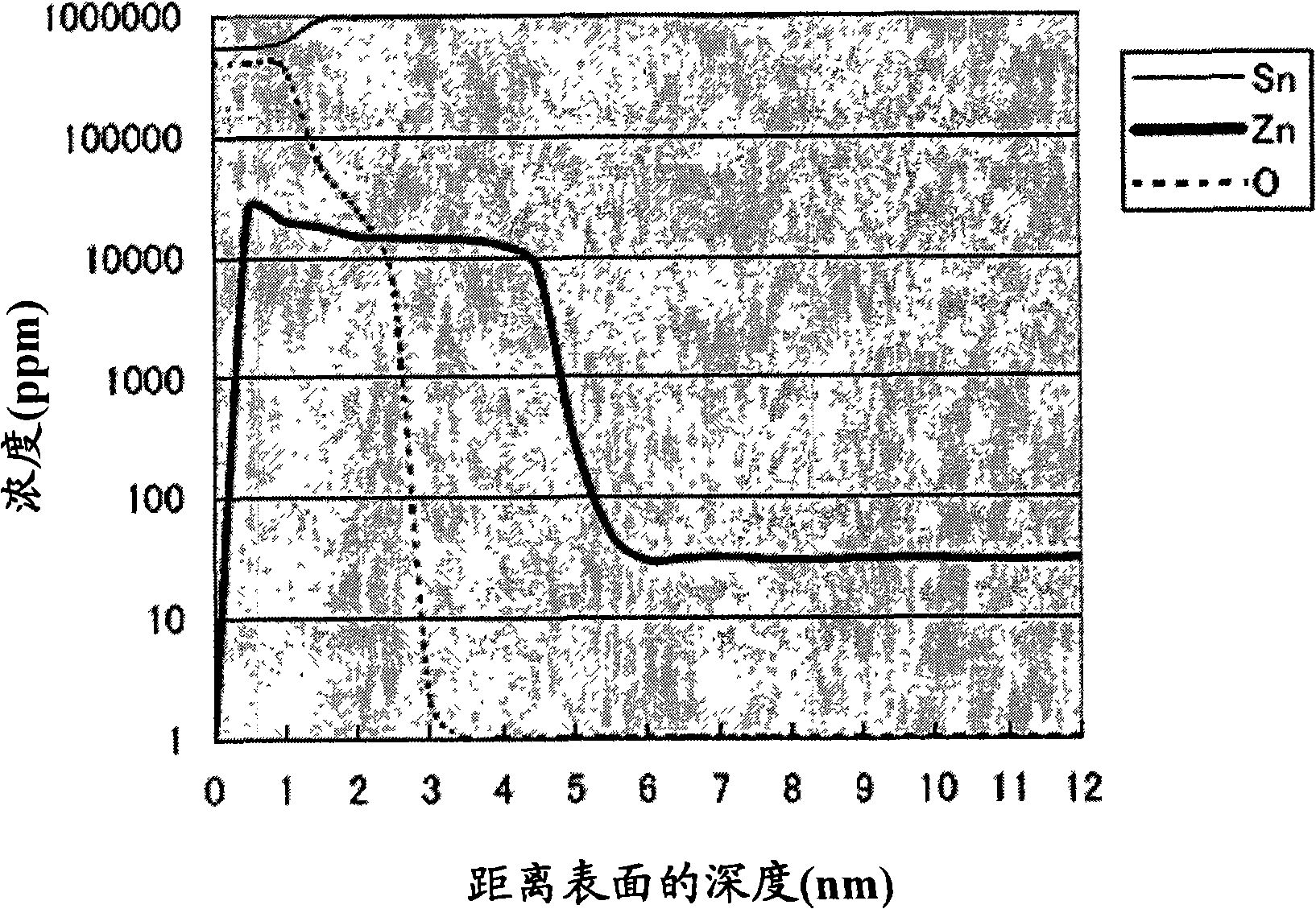

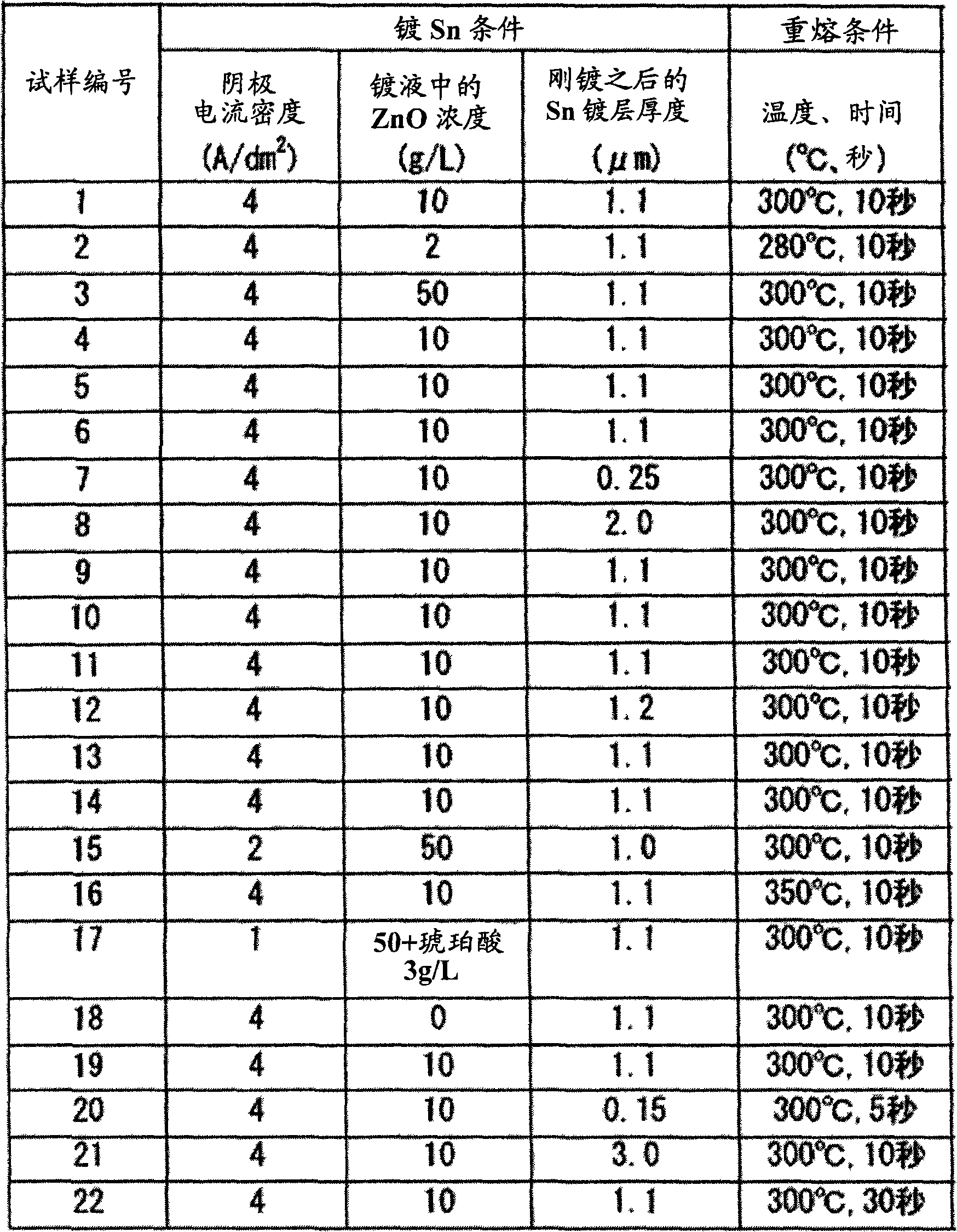

Remelting plating Sn material and electronic component using the same

ActiveCN101318390ALess weldabilityLess deterioration of contact resistanceSolid state diffusion coatingMetal layered productsElectronic componentCopper alloy

The invention provides a plating Sn material which keeps favorable weldability and low contact resistance even exposed in a high temperature environment and has low plug performance. The plating Sn material is provided with a bottom Ni plating layer, a middle Sn-Cu plating layer and a surface Sn plating layer in sequence on the surface of a copper or a copper alloy, wherein the bottom Ni plating layer is composed of Ni or Ni alloy, the middle Sn-Cu plating layer is composed of an Sn-Cu series alloy with an Sn-Cu-Zn alloy layer at least at one side adjacent to the surface Sn plating layer, and the surface Sn plating layer is composed of Sn alloy with 5-1000 weight ppm of Zn.

Owner:JX NIPPON MINING & METALS CO LTD

Preparation method for sintered Nd-Fe-B permanent-magnet material

ActiveCN103559972AImprove coercive forceHigh strengthInorganic material magnetismPhase ratioRare earth

The invention belongs to the field of rare earth permanent magnetic material, and particularly discloses a preparation method for a novel sintered Nd-Fe-B permanent-magnet material. During the sintered Nd-Fe-B preparation process, a small amount of Cu-Zn alloy nanometer powder is uniformly mixed with Nd-Fe-B powder on the basis that the phase ratio of Nd to Fe to B is 2:14:1, and the mixture is subjected to magnetic field oriented compression molding, vacuum sintering and tempering thermal treatment, so that a finished product can be obtained. In the organizational structure of the novel sintered Nd-Fe-B product, the Cu-Zn phase completely replaces the Nd-rich phase of the grain boundary in the traditional product, and has the magnetic isolation and sintering assistance functions of the Nd-rich phase, so that integrated performance such as high coercivity, high corrosion resistance and high roughness can be acquired at the same time; the method is simple to operate, easy to realize industrial production and low in production cost.

Owner:UNIV OF SCI & TECH BEIJING

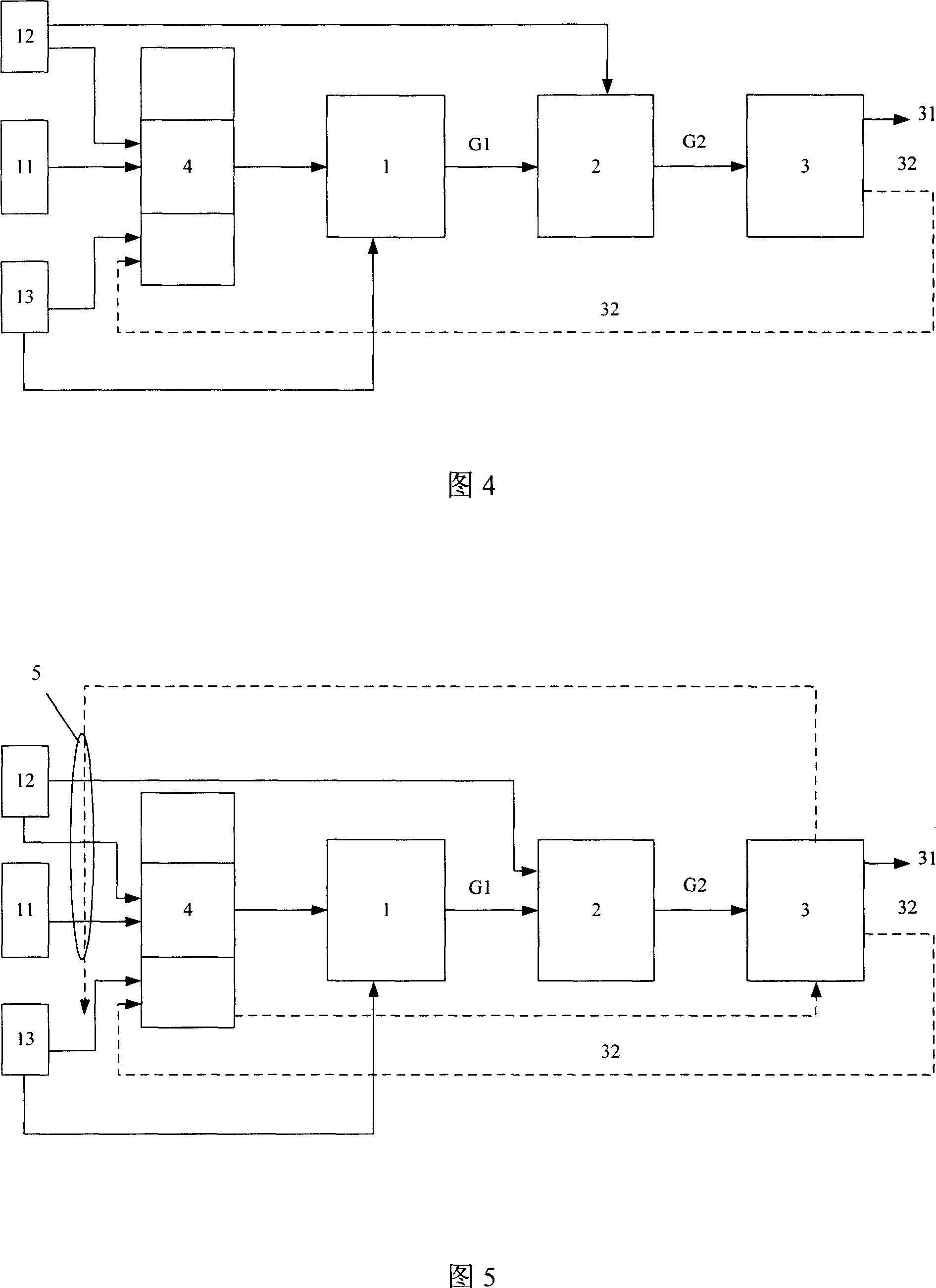

On-site hydrogen producing method and on-site hydrogen producing device

ActiveCN101148249AOvercome the disadvantage of easy passivationAvoid passivationHydrogenHydrogenCu zn alloy

The in-situ hydrogen preparing process includes contacting carbon-containing material and water inside one reforming hydrogen-making reactor in reforming hydrogen-making condition to produce hydrogen-rich gas mixture; and separating hydrogen from the gas mixture inside one hydrogen separator after contacting the hydrogen-rich gas mixture and water inside one water converting reactor in the presence of water converting catalyst containing one or several of Cu-Zn alloy, Pd-Cu alloy, Pd-Cu-Cr alloy and Pt-Ce alloy. The in-situ hydrogen preparing process has hydrogen-rich gas mixture with CO less than 2 vol% and no deactivation of the selective hydrogen penetrating film in the hydrogen separator.

Owner:BYD CO LTD

Cu-P-Ag solder containing Ga, In and Ce

ActiveCN1994658AGrain refinementImprove wettabilityWelding/cutting media/materialsSoldering mediaIndiumChemical composition

The invention relates to a copper phosphor silver solder which contains gallium, indium and cerium, wherein it comprises that: 13. 0%-18. 0% silver, 4. 0%-8. 0% phosphor, 0.001%-0.1% gallium, 0.001%-0.1% indium, 0.002%-0.10% cerium, and copper. The invention has the advantages that: it has better anti-drawing strength and anti-shearing strength, etc. It can be used to prepare wires and band; it can reduce the fusion point of alloy (Ag-Cu-Zn alloy), improve its welding property; and it adds rare-earth cerium to particle the crystals, and improve the plasticity to 18. 7-34. 7%.

Owner:CHANGSHU HUAYIN FILLER METALS

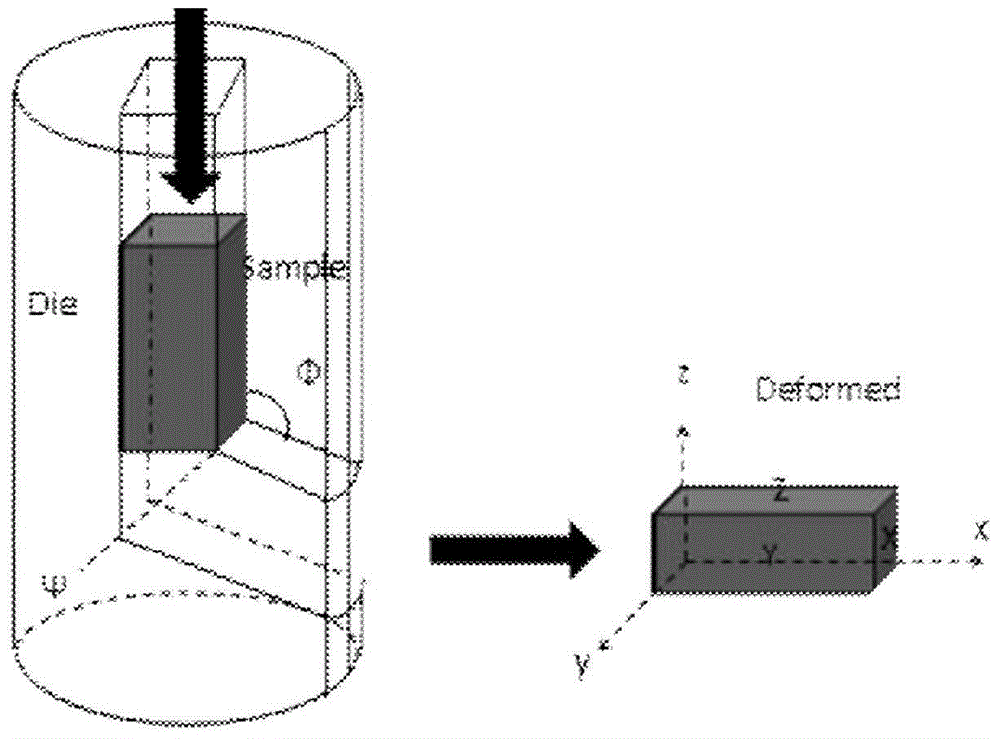

Method for preparing nano-sized twin crystal Cu-Al or Cu-Zn alloy

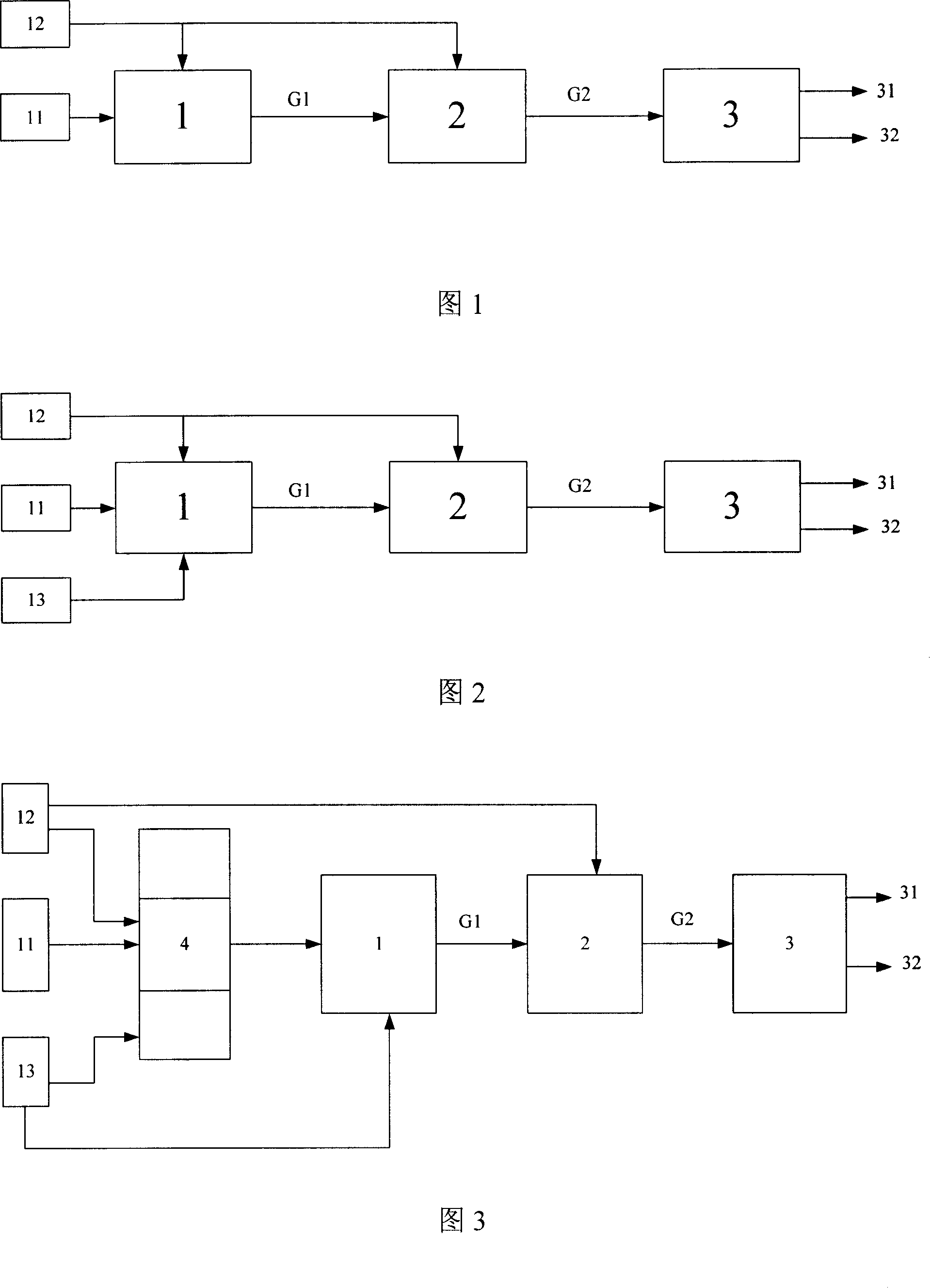

The invention provides a method for preparing a nano-sized crystal twin Cu-Al or Cu-Zn alloy. The method comprises the following steps: carrying out solution treatment on Cu-Al or Cu-Zn alloy; during solution treatment, firstly carrying out furnace cooling on the Cu-Al or Cu-Zn alloy and then cooling with saline water; soaking the Cu-Al or Cu-Zn alloy cooled by the saline water in liquid nitrogen; rapidly carrying out equal-channel pressing on the Cu-Al or Cu-Zn alloy; and carrying out subzero treatment on the Cu-Al or Cu-Zn alloy which is subjected to equal-channel pressing. The micro hardness and strength of the nano-sized twin crystal Cu-Al or Cu-Zn alloy prepared by the method are significantly improved; the nano-sized crystal twin Cu-Al or Cu-Zn alloy has good plasticity; the production process of the method is simple; and preparation of the nano-sized twin crystal alloy of a large-size sample can be achieved under the condition that the sample and the size are not changed.

Owner:CHANGZHOU UNIV

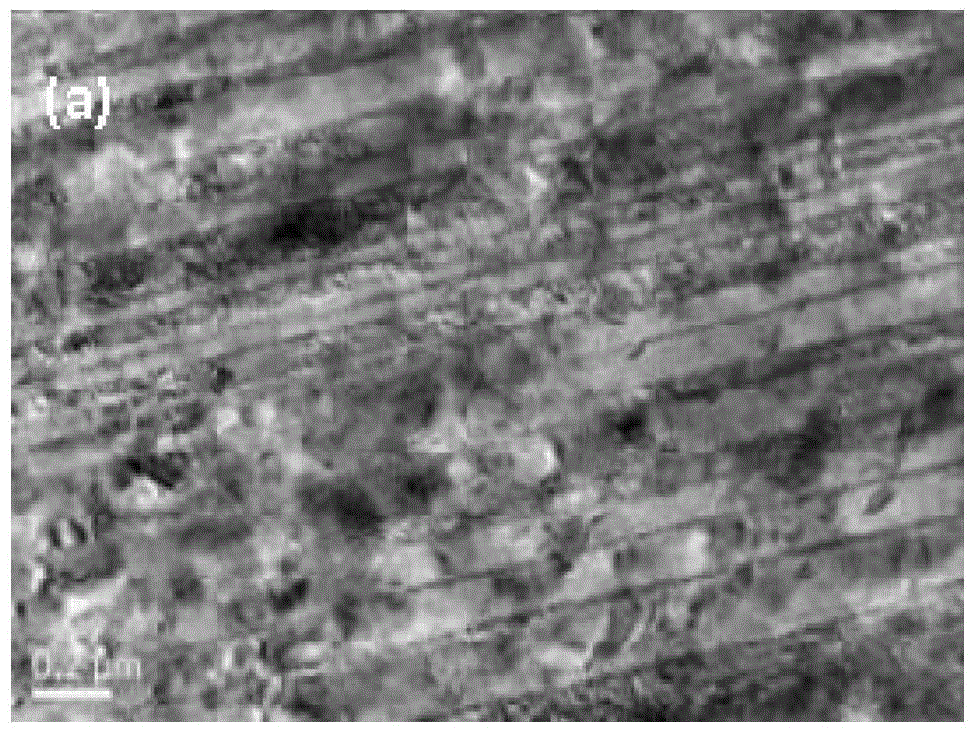

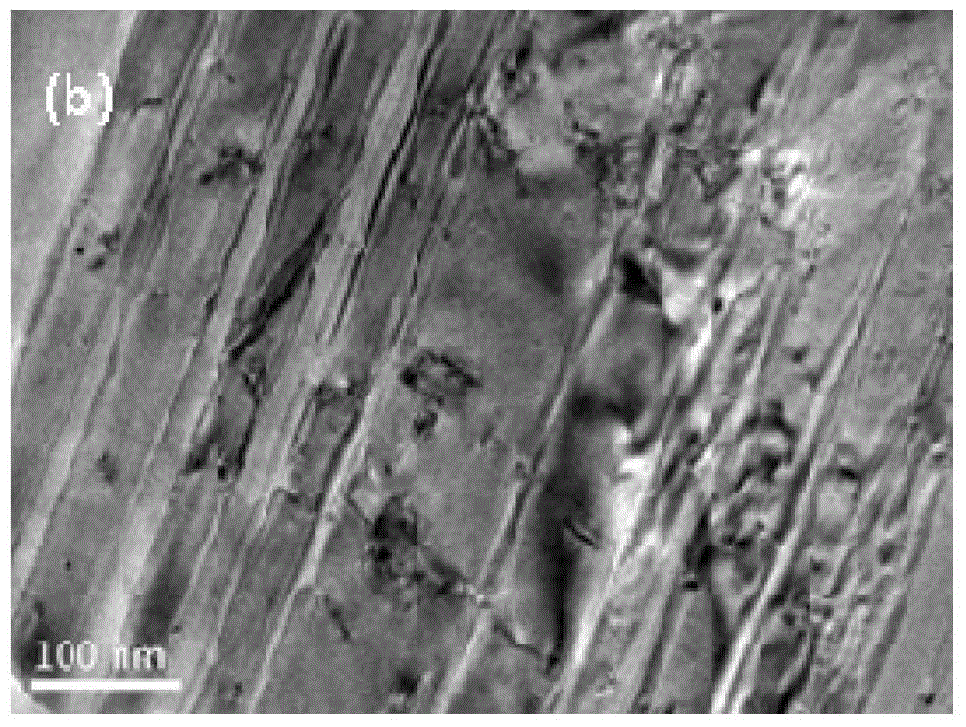

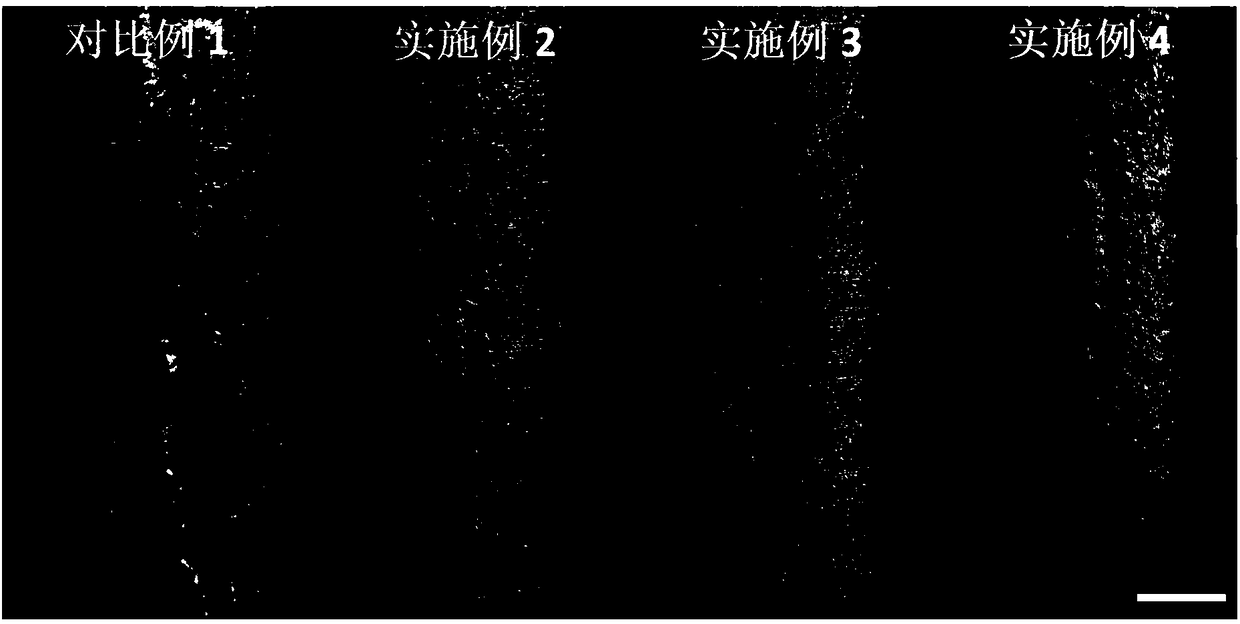

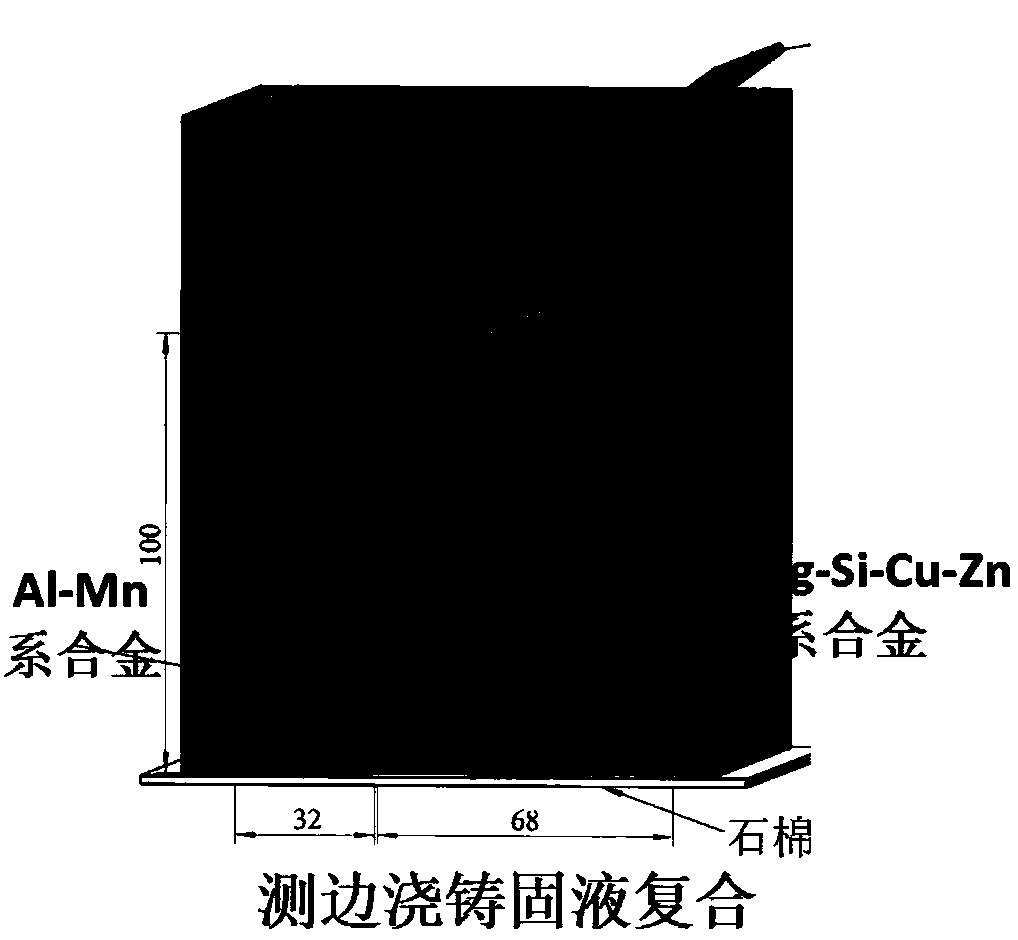

Preparation method of high-formability aluminum alloy composite board material used for vehicle body external plate

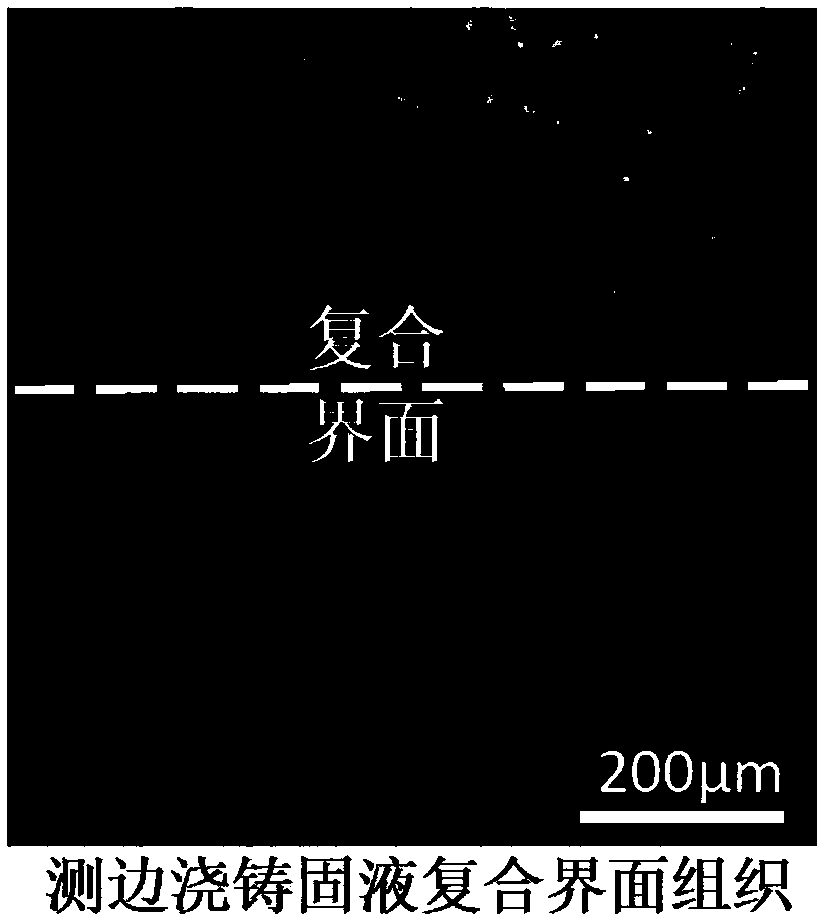

A preparation method of a high-formability aluminum alloy composite board material used for a vehicle body external plate belongs to the technical field of aluminum alloy. According to the method, high-plastic and anti-corrosion Al-Mn alloy and Al-Mg-Si-Cu-Zn alloy are composited through solid-liquid fusion casting; then through following thermo-processing for regulation, cooperative deformation of the two metals is achieved, thus producing the composite board in certain thickness ratio; in addition, the composition board has excellent formability, and is especially enhanced in flanging performance to a significant degree. The preparation method completely solves the problems of influence on the flanging performance due to residual micro-cracks in a coarse iron-rich phase due to incompletecrushing of a part of the Al-Mg-Si-Cu-Zn alloy, so that the alloy board material has very excellent comprehensive performance. The high-formability aluminum alloy composite board material is very suitable for manufacturing the vehicle body external plate, especially manufacturing parts, which have high demands on stamping shaping performance, flanging performance and stoving varnish hardening increment, in complex shapes.

Owner:UNIV OF SCI & TECH BEIJING

Medical biodegradable zn-cu alloy and its preparation method as well as applications

InactiveUS20170218483A1Accurate Mechanical PropertiesEasy to processStentsBone implantZinc alloysBiocompatibility

The present invention relates to the preparation methods and applications of biodegradable zinc-copper alloys, which can be applied to medical implant materials. The alloy of present invention is mainly composed of copper (1-10 wt. %), the balance of zinc and trace impurity elements. As-cast alloy ingot is homogenized and then hot processed to refine microstructure. The mechanical properties of the alloys are improved due to the refined microstructure. The alloys are capable of being further fabricated into micro-tubes, wires and plates. There are many advantages of these Zn alloys such as excellent mechanical properties, easy to process, appropriate corrosion resistance, good biocompatibility and so on, which correspondingly can be applied to many kinds of biodegradable medical implant devices. With excellent mechanical properties, good biocompatibility and degrading completely in 6-18 months, the Zn alloys meet the requirements of implant materials for mechanical properties and biosafety.

Owner:SHANGHAI JIAO TONG UNIV

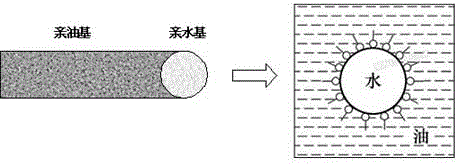

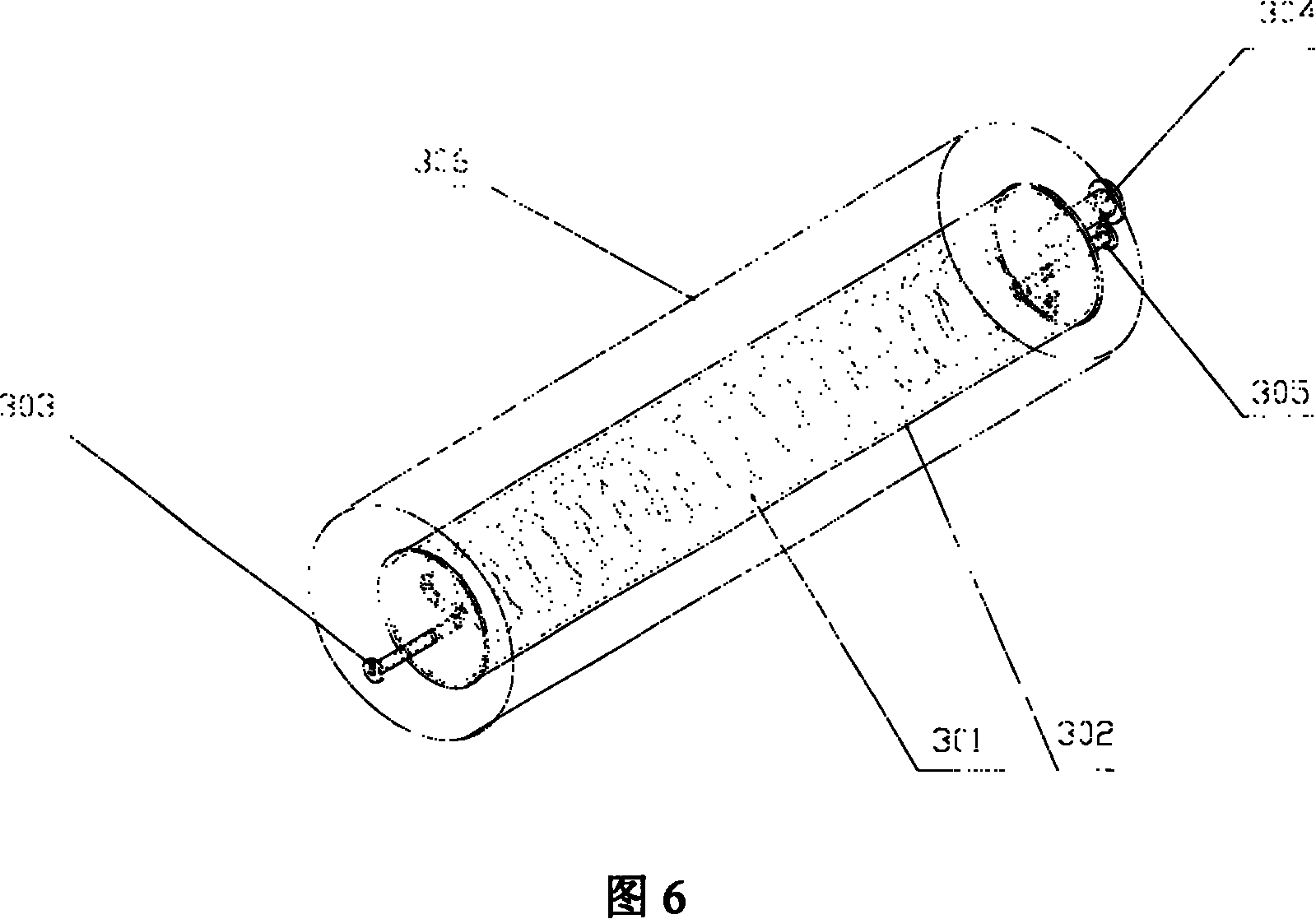

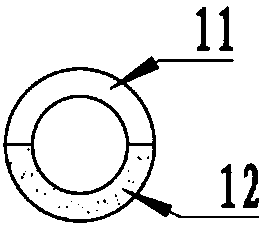

Cu-Zn (copper-zinc)/polysulfone inorganic-organic hollow fibrous hybrid membrane and preparation method thereof

ActiveCN108310987AImprove hydrophilicityHigh mechanical strengthSemi-permeable membranesMembranesHollow fibreFiber

The invention belongs to the field of fibrous membrane materials, and discloses a Cu-Zn (copper-zinc) / polysulfone inorganic-organic hollow fibrous hybrid membrane and a preparation method thereof. Thepreparation method comprises the following steps of dissolving polysulfone into an organic solvent, adding a PVP (polyvinyl pyrrolidone) additive and Cu-Zn metal powder, and uniformly stirring and mixing, so as to obtain a membrane casting liquid; defoaming the membrane casting liquid under the vacuum condition, pouring into a spinning device, pushing to a spinning head by air pressure, extrudingand forming, condensing and forming by internal and external condensing baths, soaking into pure water, and naturally airing, so as to obtain the Cu-Zn / polysulfone inorganic-organic hollow fibrous hybrid membrane. The prepared Cu-Zn / polysulfone inorganic-organic hollow fibrous hybrid membrane has the advantages that the self-supporting function is realized, any supporter is not needed, the mechanical strength is high, and the separating property is good; the Cu-Zn alloy in the membrane can improve the hydrophilia of the membrane, and effectively remove the residual chloride in water; the application prospect is good.

Owner:SOUTH CHINA UNIV OF TECH

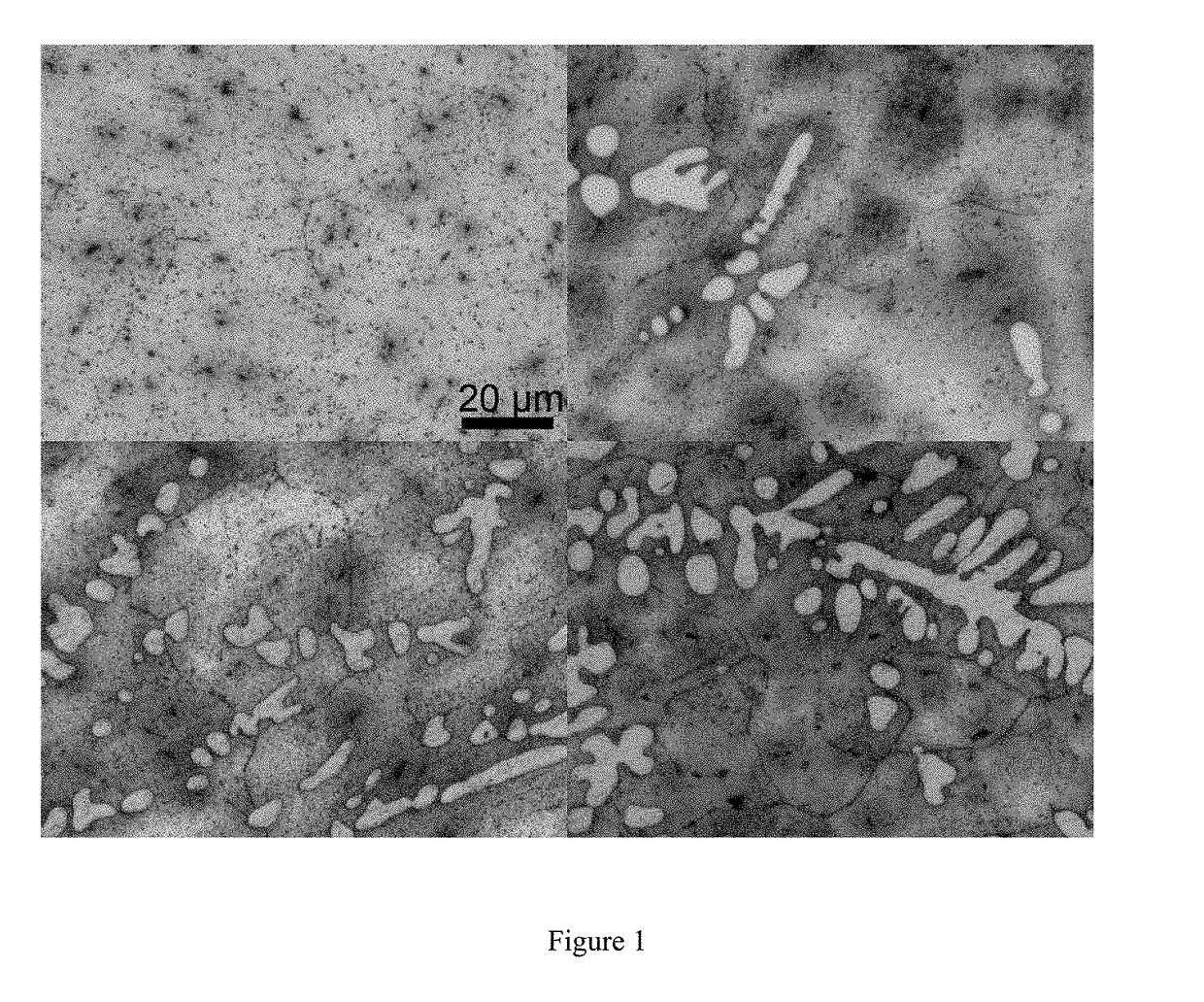

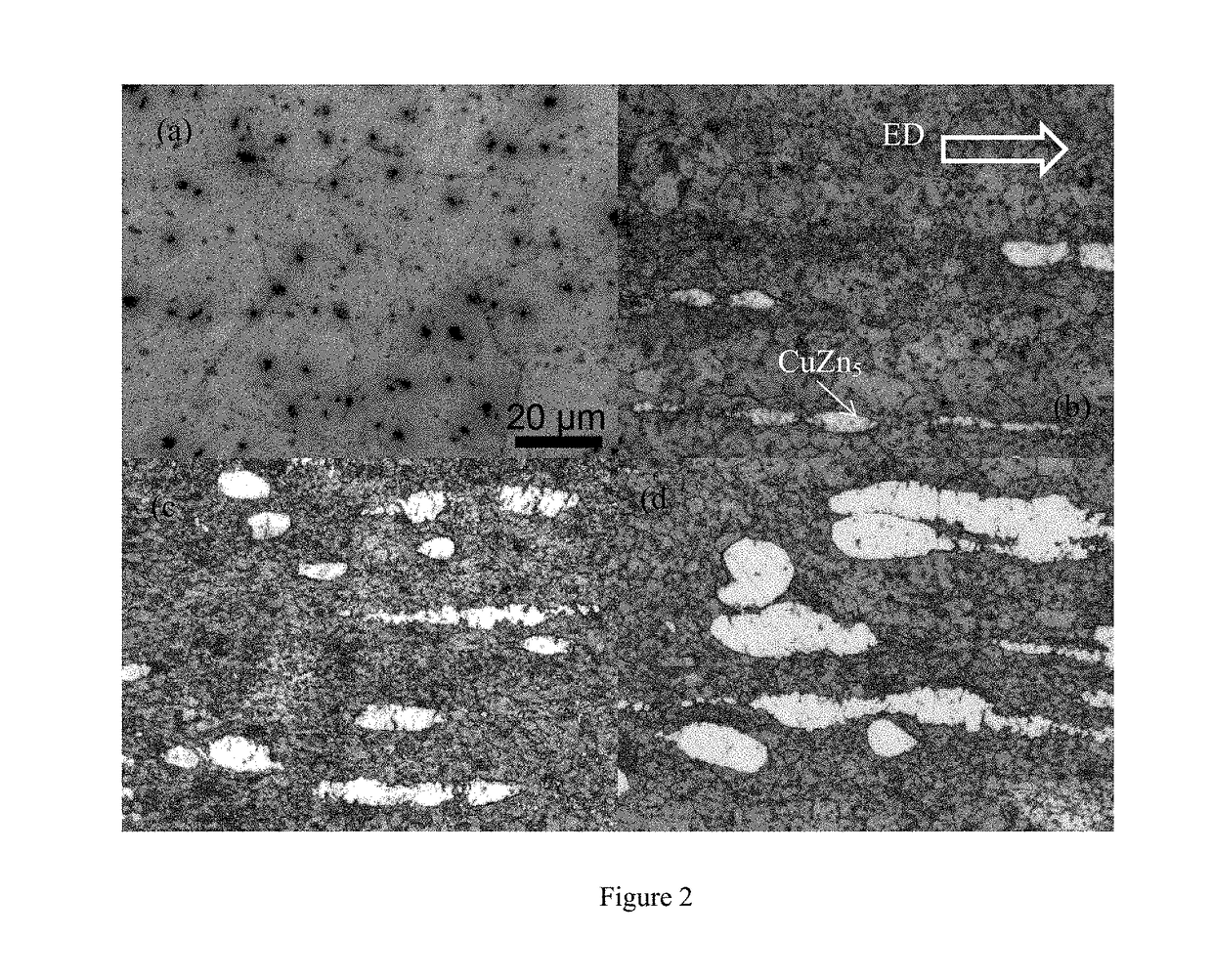

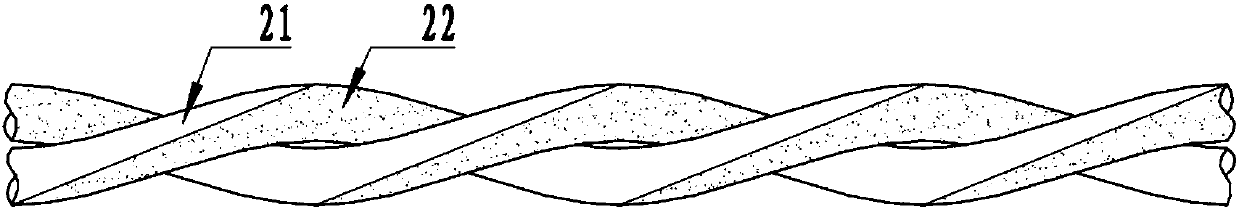

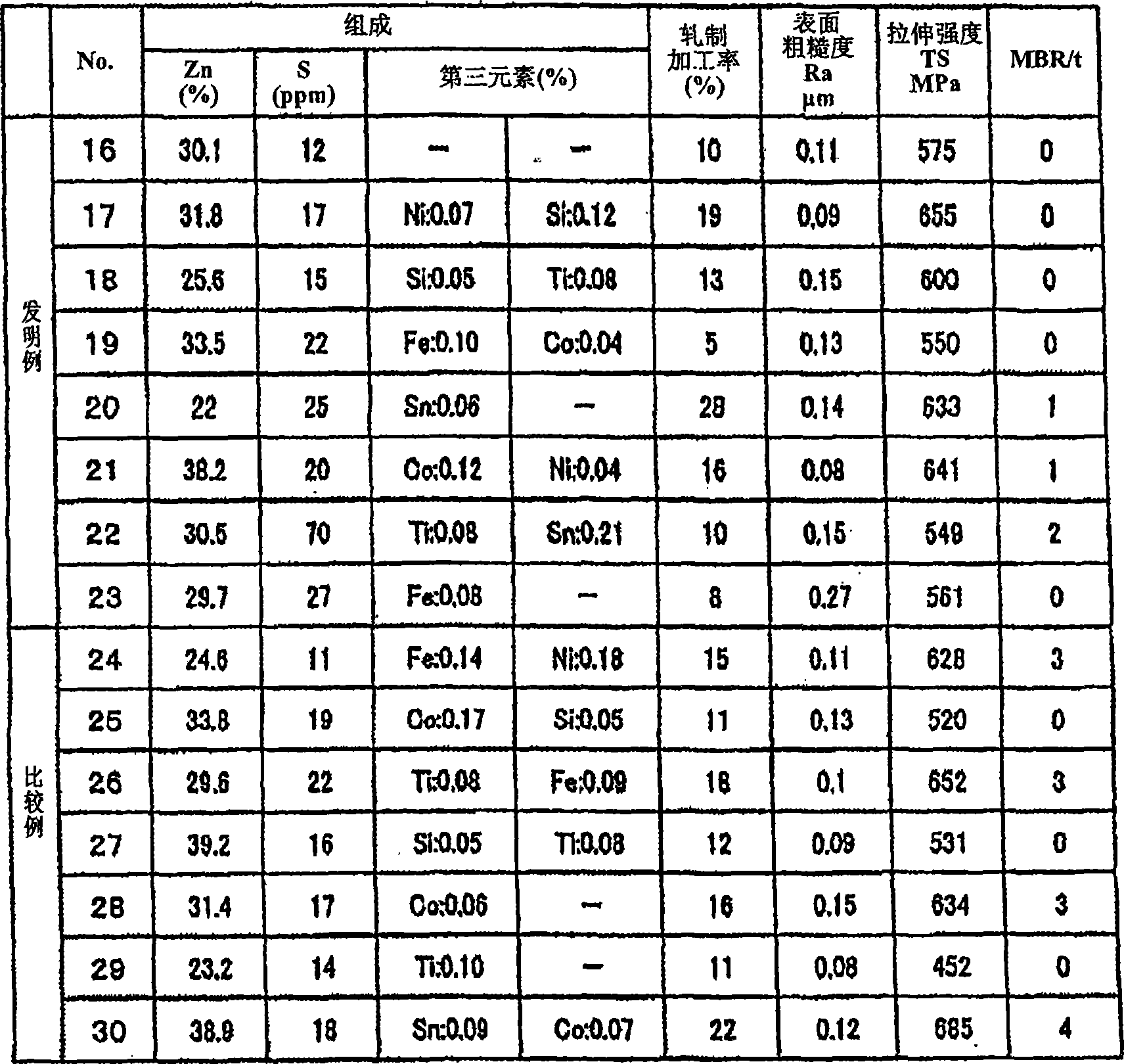

Metal wire, manufacturing method thereof and tire

ActiveCN107824630AGood wet heat aging adhesionPneumatic tyre reinforcementsFurnace typesManganeseAlloy coating

The invention discloses a metal wire, a manufacturing method thereof and a tire. The metal wire is manufactured by stranding monofilaments. The outer circle face of each monofilament is covered with aCu-M-Zn alloy coating. The metal wire is characterized in that the outer circle face of each monofilament is covered with a Cu-Zn alloy coating, the number of the monofilaments for manufacturing themetal wire is at least one, the coverage area of each Cu-M-Zn alloy coating is 10-90% of the area of the outer circle face of each monofilament, and the rest are Cu-Zn alloy coatings; M in each Cu-M-Zn alloy coating is selected from one or two of cobalt, nickel, manganese and molybdenum; the mass fraction of copper in each Cu-M-Zn alloy coating is 58-72%, the mass fraction of M in each Cu-M-Zn alloy coating is 0.5-5%, and the balance in each Cu-M-Zn alloy coating is zinc and inevitable impurities. The metal wire has the beneficial effects that each monofilament for forming the metal wire is provided with two kinds of alloy coatings at the same time, and thus, the metal wire has good initial adhesive force and damp-heat aging adhesive force at the same time and is particularly applicable torubber components which do not contain cobalt.

Owner:JIANGSU XINGDA STEEL TYPE CORD

Method for manufacturing complex copper-zinc alloy

The invention relates to a method for manufacturing a complex copper-zinc alloy, which comprises the following steps: collecting materials, and selecting Zn, C, Mn, Si, Nb, Ti, V, Mo, Cr, Al and Cu in a certain proportion; placing the above materials in a 5t cover-type resistance furnace for smelting; degassing and deslagging in the smelting process, and carrying out high cleanliness refining; casting into a casting mold of an alloy; annealing for 24 hours at a temperature of 440-460 DEG C; processing an as-cast alloy into a column-shaped test piece by linear cutting; carrying out surface preprocessing on the cut test piece, and uniformly coating a solid lubricant on the surface of the cut test piece; continuously carrying out equal channel angular pressing on the cut test piece for 7-10 times; placing the test piece subjected to the equal channel angular pressing into an annealing furnace to be heated to 600 DEG C, and holding the temperature for 30 minutes; and taking out the test piece and carrying out oil quenching to the room temperature. The method provided by the invention is characterized in that crystal particles and second phase distribution shapes of Cu-Zn alloys are further refined, and the stability, the strength and the toughness of the alloy are improved; and the process operation and the equipment requirements are simple.

Owner:东莞市发斯特精密科技股份有限公司

Brass coated composite iron powder and its production process

The brass clad iron composite powder is formed through forming cladding brass layer on Cu clad Fe composite powder, and contains Cu 5-40 wt%, Zn 0.05-40 wt% and Fe for the rest. The brass clad iron composite powder is produced through mixing Cu clad Fe composite powder and Cu-Zn alloy powder or Zn powder, reducing adhesion or reducing diffusion in a reducing furnace at temperature of 450-800 deg.c for over 30 min to form cladding Cu-Zn alloy layer on Cu clad Fe composite powder, crushing, sieving, mixing and other steps. The present invention has the advantages of low cost, simple technological process, no environmental pollution, high antioxidant performance, etc.

Owner:重庆扬子粉末冶金有限责任公司

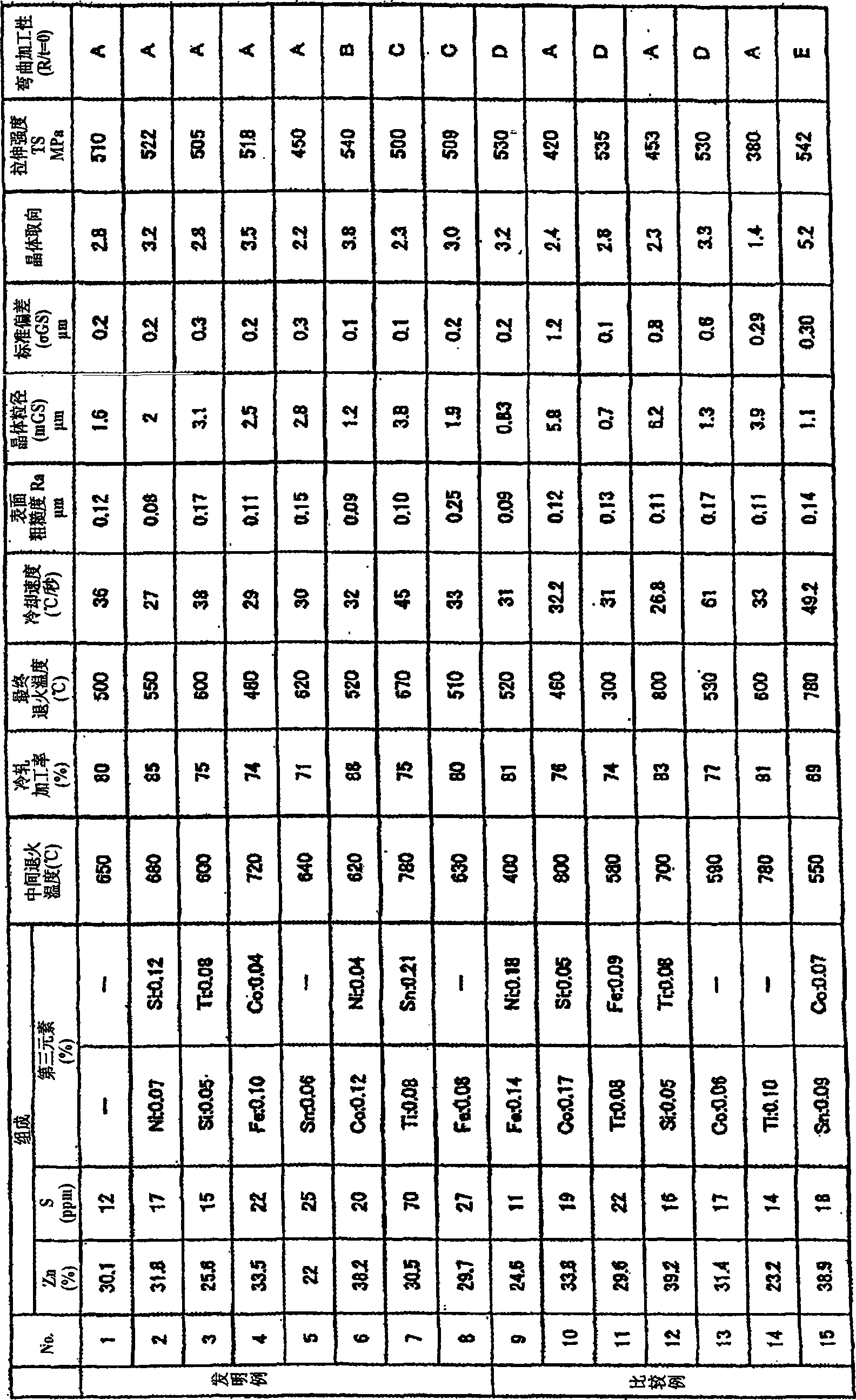

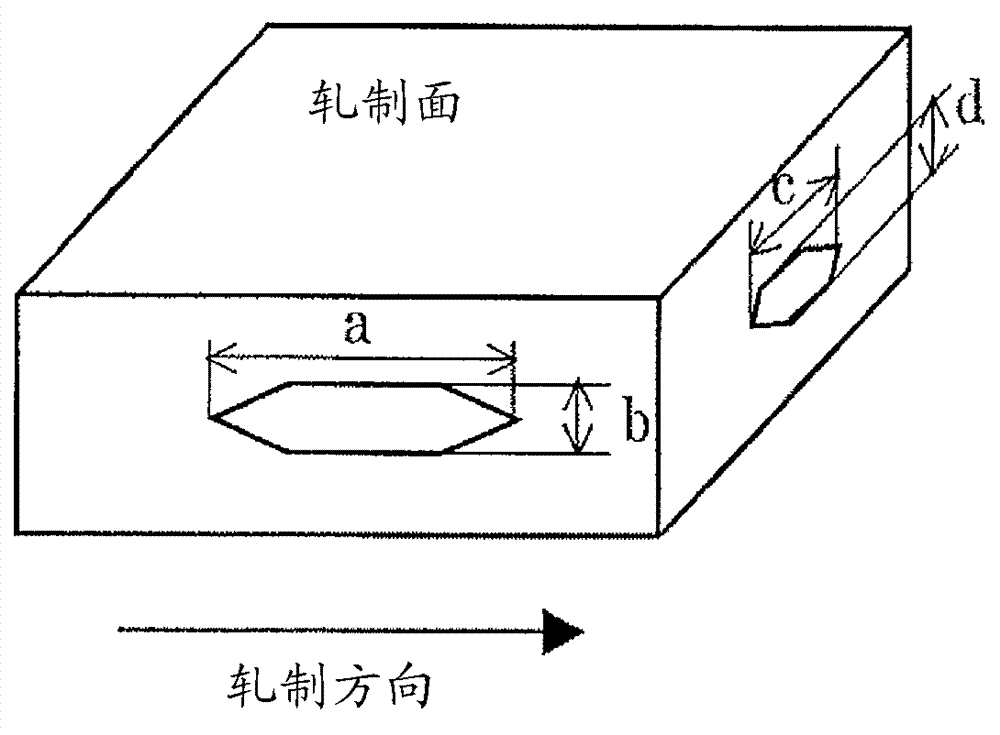

Cu-zn alloy with high strength and excellent bendability

A Cu-Zn copper alloy which is for use in electronic parts such as terminals and connectors and has high strength and excellent bendability. The Cu-Zn alloy having high strength and excellent bendability comprises 20-40 mass% Zn and, as the remainder, Cu and unavoidable impurities, and has such crystal grain characteristics that the average crystal grain diameter (mGS) is 1-4 [mu]m and the standard deviation (sGS) of the crystal grain diameters is 1 / 3 mGS or less. In the alloy, the relationship {I(220)+I(111 / I(200) between X-ray diffraction intensities in an examination of a rolled plane is 2.0-5.0. The Cu-Zn alloy may further contain any one or more of Ni, Si, Fe, Ti, Co, and Sn in an amount of 0.01-0.3 mass%. The alloy preferably has a sulfur content of 30 ppm or lower and has a surface roughness (Ra) of 0.2 [mu]m or lower.

Owner:JX NIPPON MINING & METALS CO LTD

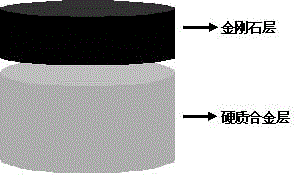

High-service-life marble cutter head blank body and manufacturing method of cutter head

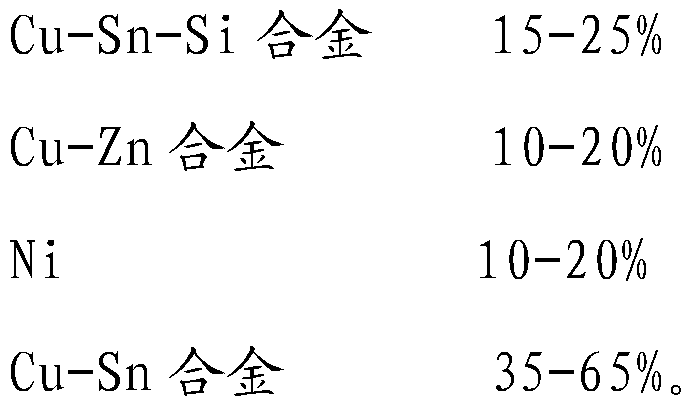

ActiveCN110449588AReasonable brittlenessImprove versatilityTurbinesOther manufacturing equipments/toolsWear resistanceToughness

The invention discloses a high-service-life marble cutter head blank body and a manufacturing method of a cutter head. The high-service-life marble cutter head blank body comprises the following components, in percentage by weight, of 15%-25% of Cu-Sn-Si alloy, 10%-20% of Cu-Zn alloy, 10%-20% of Ni and 35%-65% of Cu-Sn alloy. According to the cutter head blank body, due to the introduction of specific new materials and the reasonable allocation among all components, the brittleness, the wear resistance and the toughness of the blank body are more reasonably fused, the universality of the blankbody is effectively enhanced, the diamond cutter head can be suitable for cutting various types of marble, and the service life is prolonged by 20%-30% under the condition that sharpness is kept.

Owner:泉州众志金刚石工具有限公司

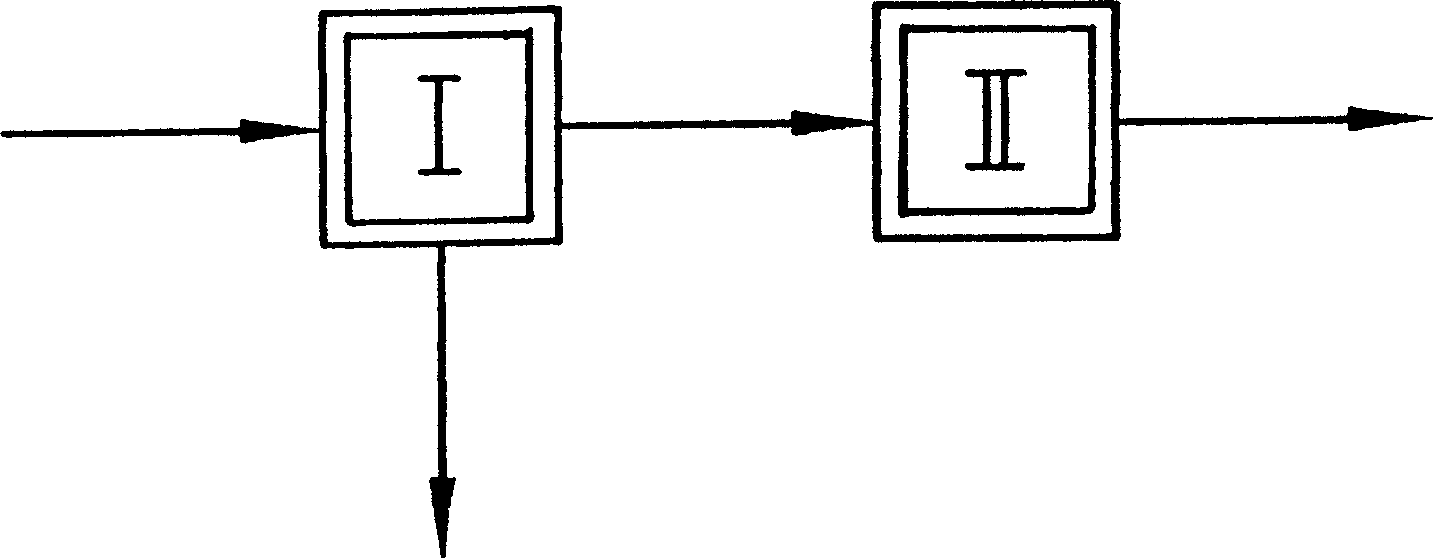

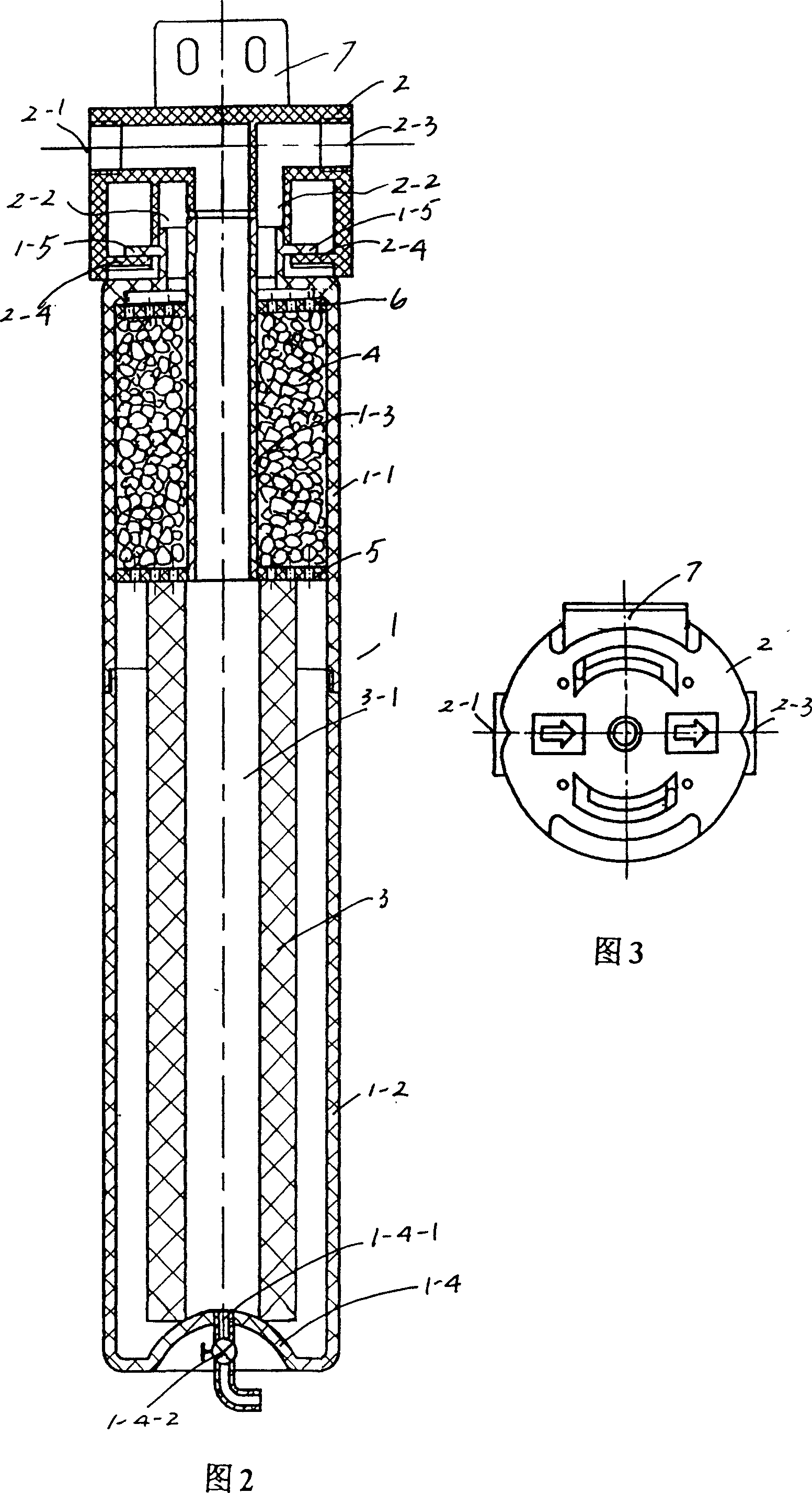

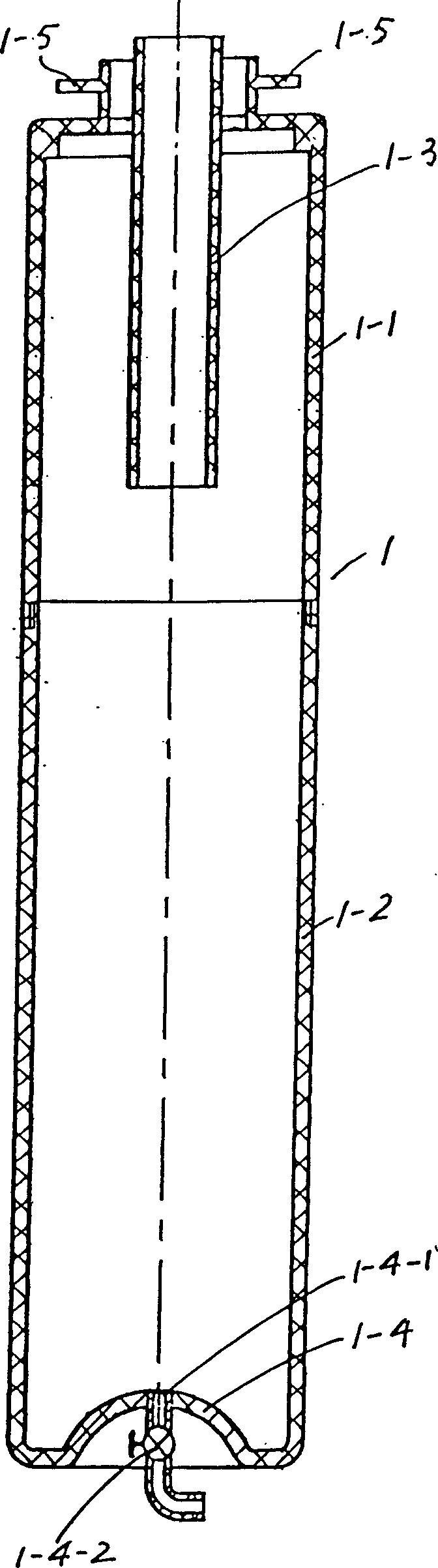

Method for preparing purified water and apparatus therefor

InactiveCN1621357AShort processImprove purification effectSemi-permeable membranesOther chemical processesHollow fibreFiber

The present invention is purified water preparing method and apparatus, and belongs to the field of water processing technology. The present invention treats material water through two stages of filtering and detoxicating, and in the detoxicating stage, detoxicating mixture of high purity Cu-Zn alloy grain and active high-iodine and silver-carrying active carbon grain is used. The water purifying apparatus includes one casing separated into upper and lower parts; one superfine hollow fiber filtering barrel, one first filtering board, one detoxicating mixture layer and one second filtering board successively arranged inside the casing; and one cover. Water is filtered in the filtering barrel and detoxicated with the detoxicating mixture before being led out via the purified water outlet in the end cap. The present invention has high water purifying effect.

Owner:卢寅岳

Method of electroplating a copper-zinc alloy thin film on a copper surface using a chemical solution

InactiveUS6528424B1Reduce resistanceImprove the immunityElectrolysis componentsSemiconductor/solid-state device manufacturingChemical solutionZinc alloys

A method of fabricating a semiconductor device, having a Cu-rich Cu-Zn alloy thin film (30) formed on a cathode-wafer such as a Cu surface (20) by electroplating, using an electroplating apparatus, the Cu surface (20) in a unique chemical solution containing salts of zinc (Zn) and copper (Cu), their complexing agents, a pH adjuster, and surfactants; and a semiconductor device thereby formed. The method controls the parameters of pH, temperature, and time in order to form a uniform Cu-rich Cu-Zn alloy thin film (30) for reducing electromigration on the cathode-wafer by decreasing the drift velocity therein which decreases the Cu migration rate in addition to decreasing the void formation rate, for improving device reliability, and for increasing corrosion resistance.

Owner:ADVANCED MICRO DEVICES INC

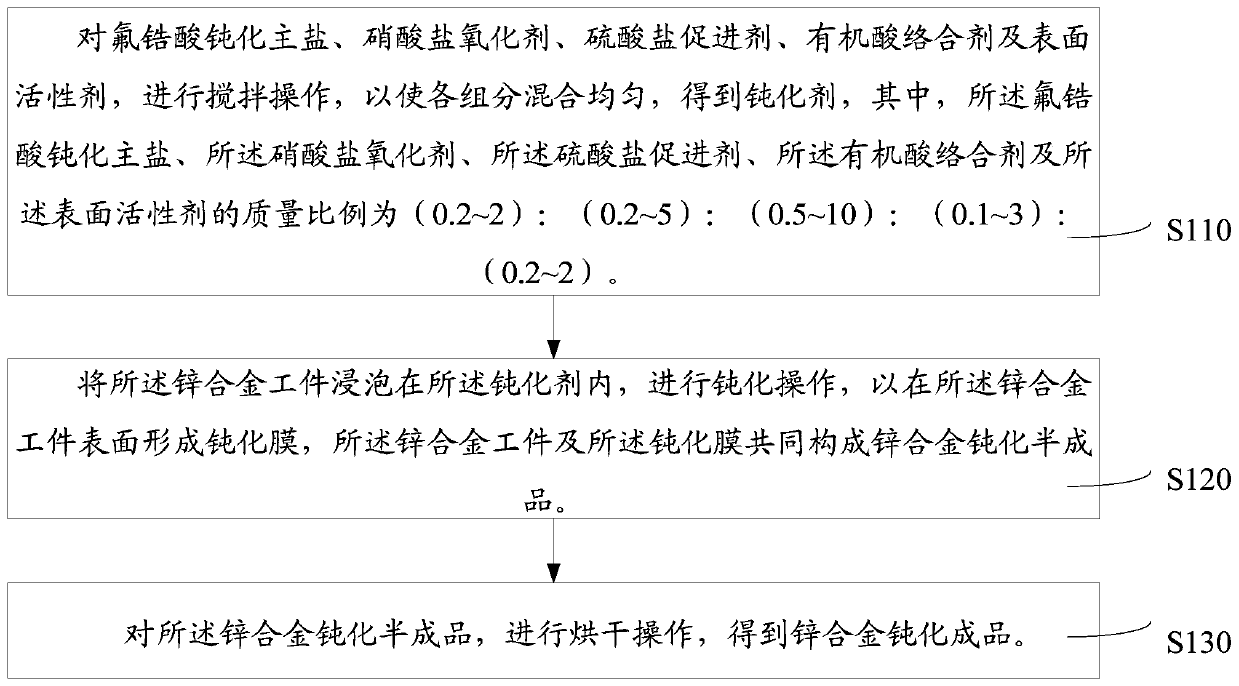

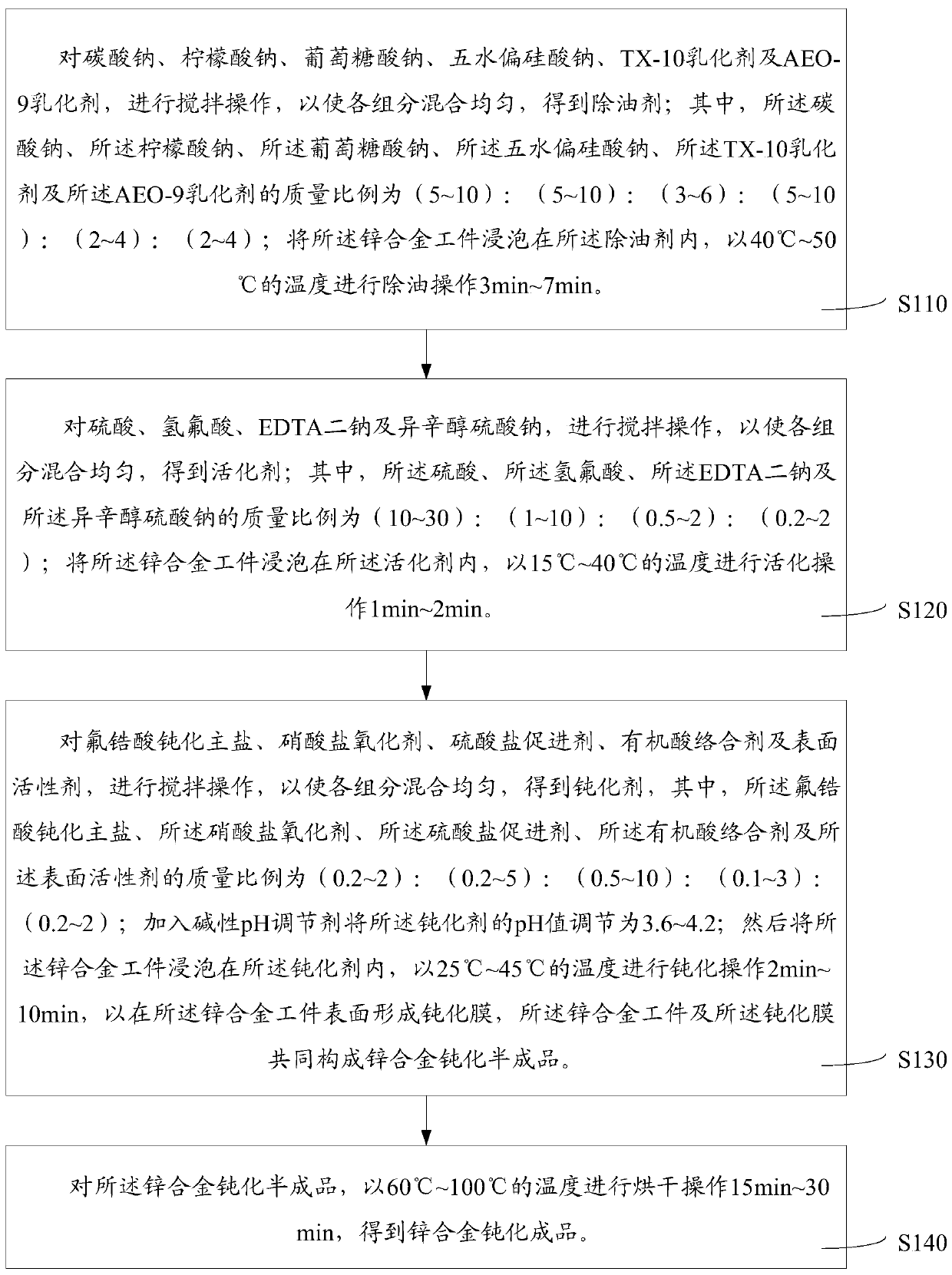

Zinc alloy passivation treatment method and passivator

ActiveCN110904445AAvoid problems prone to precipitationImprove color vibrancyMetallic material coating processesProcess efficiency improvementActive agentZinc alloys

The invention relates to the technical field of metal passivation, and discloses a zinc alloy passivation treatment method and a passivator. The passivator includes the following components in parts by weight: 0.2 to 2 parts of fluorozirconic acid passivation main salt, 0.2 to 5 parts of nitrate oxidant, 0.5 to 10 parts of sulfate accelerator, 0.1 to 3 parts of organic acid complexing agent and 0.2 to 2 parts of surfactant. The zinc alloy passivation treatment method includes steps such as degreasing, activation, passivation, drying and the like to form a passivation film on the surface of a zinc alloy workpiece to obtain a zinc alloy passivation product. The zinc alloy passivation treatment method uses no phosphorus and hexavalent chromium, the obtained passivation film has the characteristics of high film formation uniformity, high color vividness and high brightness, good bonding force with zinc alloy workpieces, high corrosion resistance, and high adhesion to coatings.

Owner:广东东明新材科技有限公司

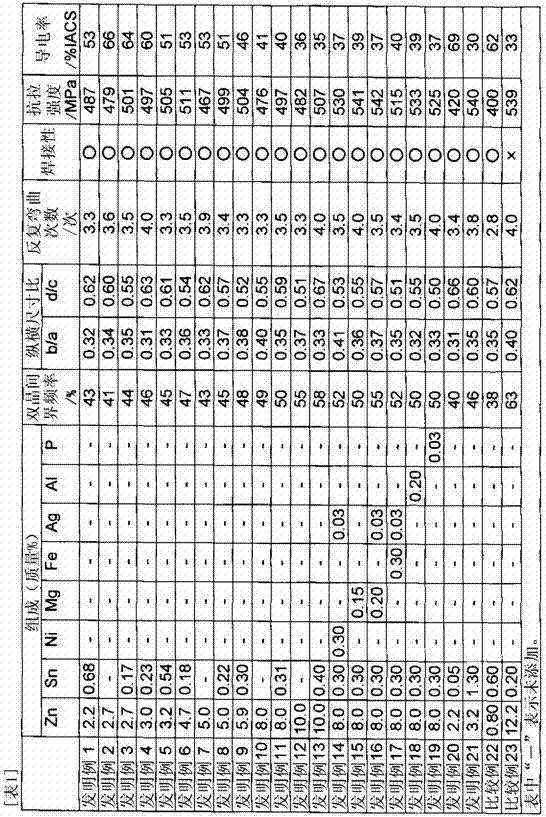

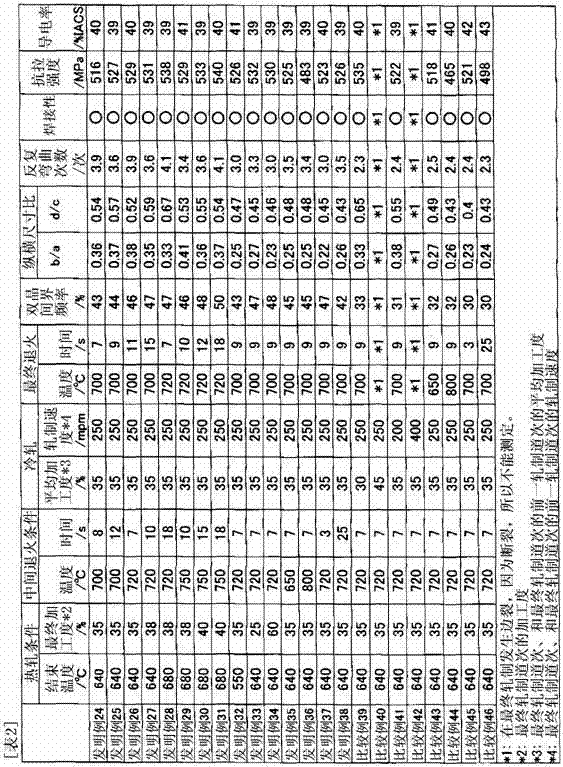

Cu-Zn alloy strip for tab material for connecting cells

InactiveCN102812137AHigh repeatabilityGood welding performanceCell component detailsRechargeable cellImpurity

Provided is a Cu-Zn alloy strip which is a copper alloy containing 2-12 mass% Zn, with the remainder comprising Cu and incidental impurities, and in which the frequency of twin-crystal boundaries is 40-70%. The alloy strip has satisfactory resistance to repeated flexing and satisfactory weldability and is suitable for use as a tab material for connecting rechargeable cells. The alloy strip may further contain 0.1-0.8 mass% Sn, and may have an aspect ratio of 0.3-0.7 in terms of aspect ratio between crystal grain diameter in the direction parallel to the rolling direction and crystal grain diameter in a direction perpendicular to the rolling direction. The alloy strip may further contain at least one of Ni, Mg, Fe, P, Al, and Ag in a total amount of 0.005-0.5 mass%. Also provided is a Sn-plated Cu-Zn alloy strip which is obtained by plating the Cu-Zn alloy with Sn in a thickness of 0.3-2 [mu]m.

Owner:JX NIPPON MINING & METALS CO LTD

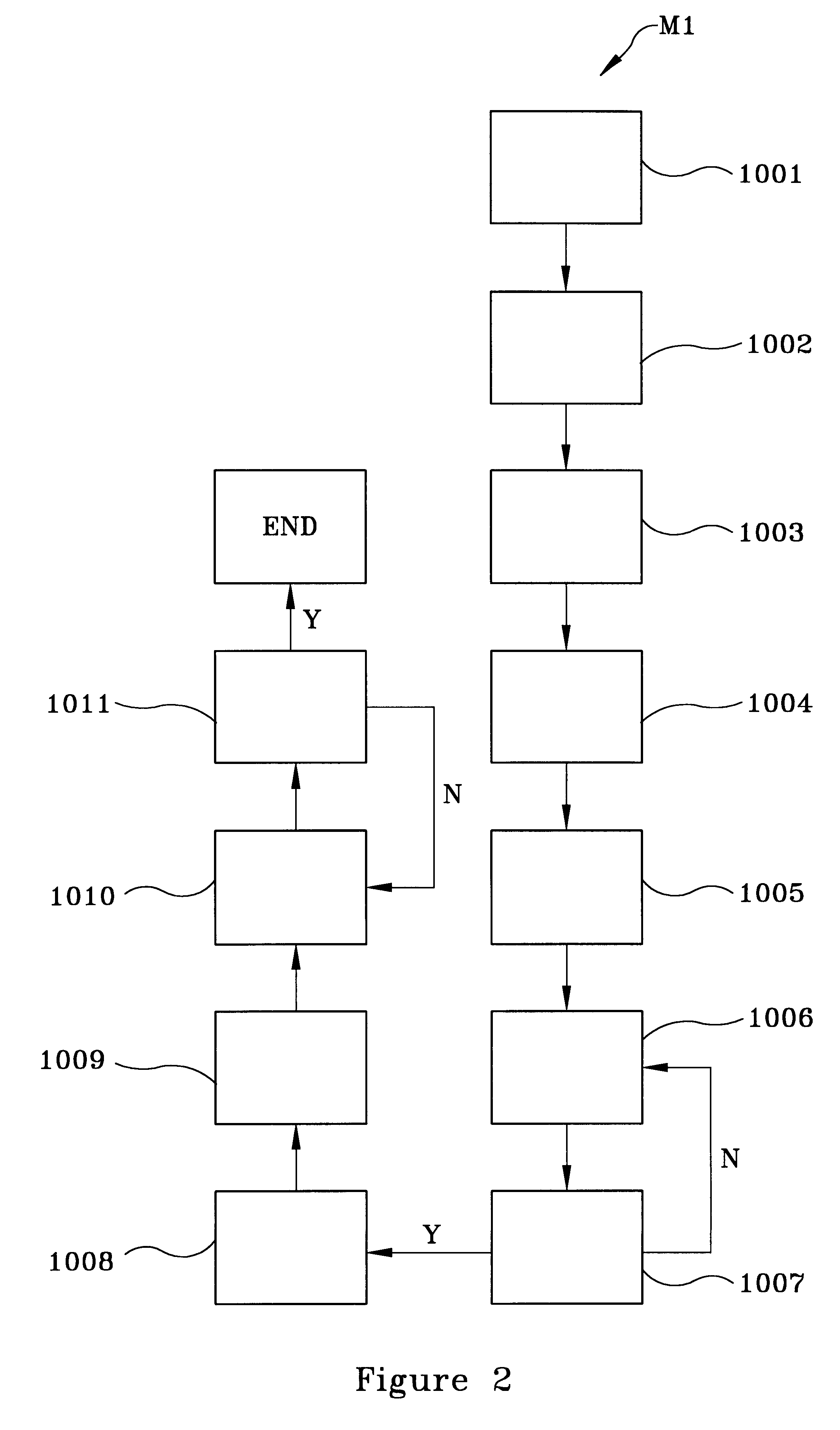

Method of controlling zinc-doping in a copper-zinc alloy thin film electroplated on a copper surface and a semiconductor device thereby formed

InactiveUS6811671B1Improves Cu interconnect reliabilityReduce manufacturing costCellsAnodisationChemical solutionZinc alloys

Owner:ADVANCED MICRO DEVICES INC

Manufacturing method of complex copper-zinc alloy shell

The present invention relates to a manufacturing method of a complex copper-zinc alloy shell. The method comprises the following steps: 1) sampling: selecting a certain ratio of Zn, C, Mn, Si, Nb, Ti, V, Mo, Cr, Al and Cu; 2) placing the materials in a 5t cover-type resistance furnace for smelting with gas and slag removal, thus carrying out refining with high cleanliness; 3) moulding a shell; 4) carrying out homogeneous annealing treatment for 24 h at of 440 to 460 DEG C. The invention is characterized in that the method optimizes composition of complex copper zinc alloy through experiment and combines with a heat treatment technology, so as to further refine crystal grains and distribution morphology of the second phase of the Cu-Zn alloy, improve stability, strength and toughness of the alloy, and in that the process operation and equipment requirement are simple.

Owner:朱春来

Nano-composite electroplating solution, preparing method of nano-composite electroplating solution and zinc alloy electroplated part

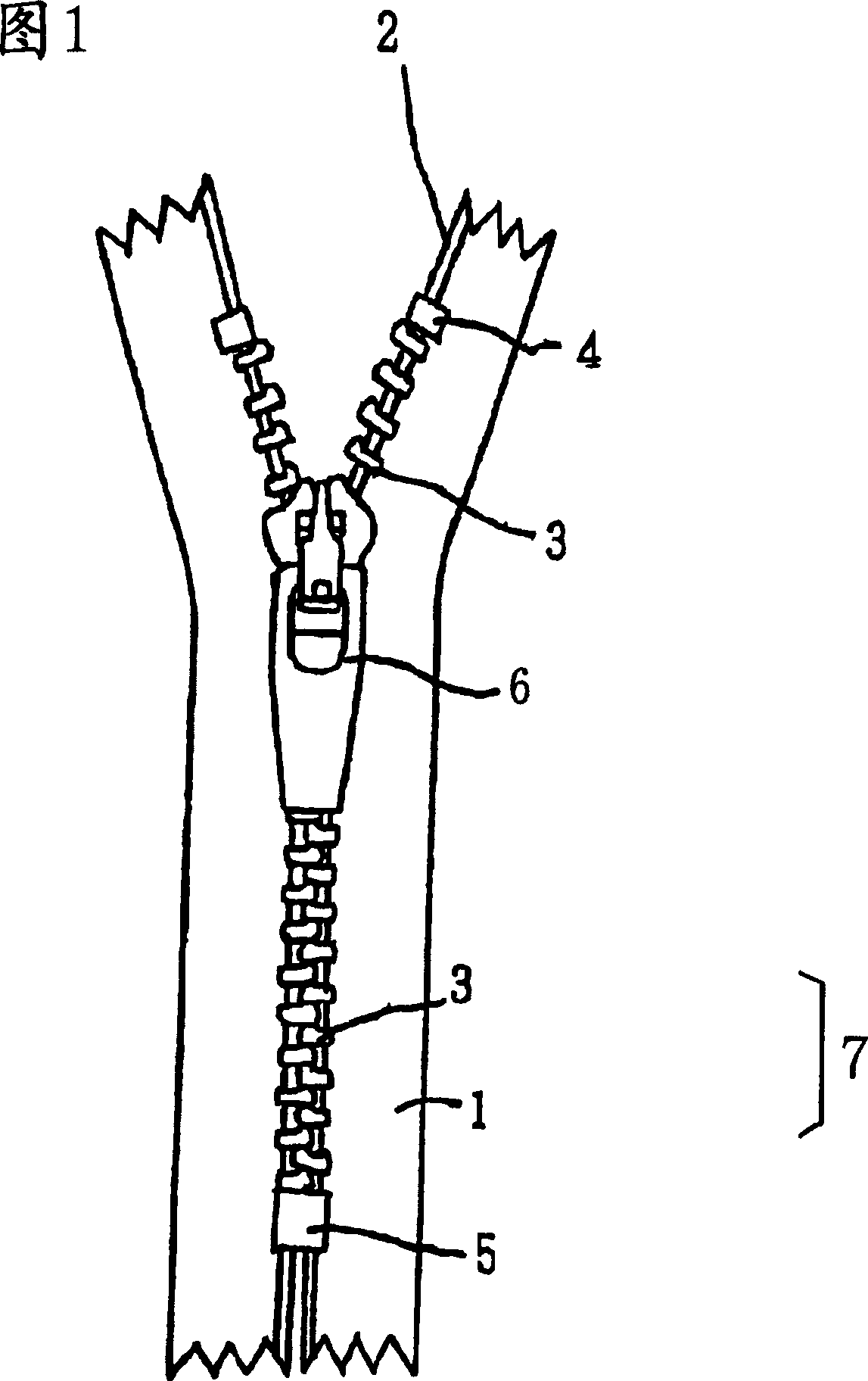

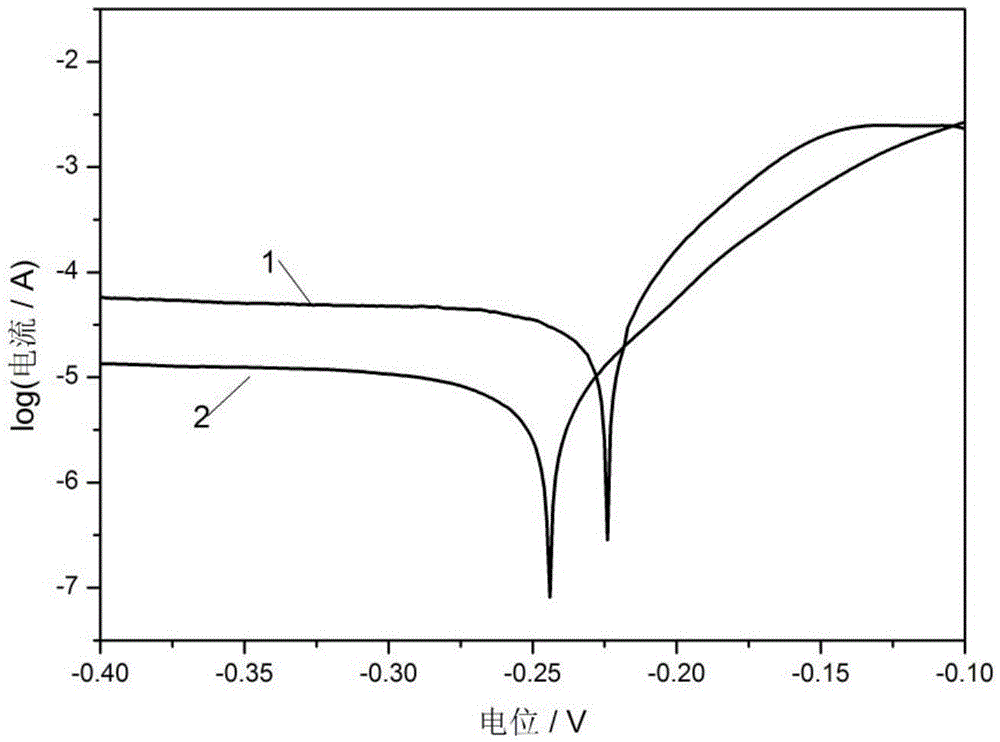

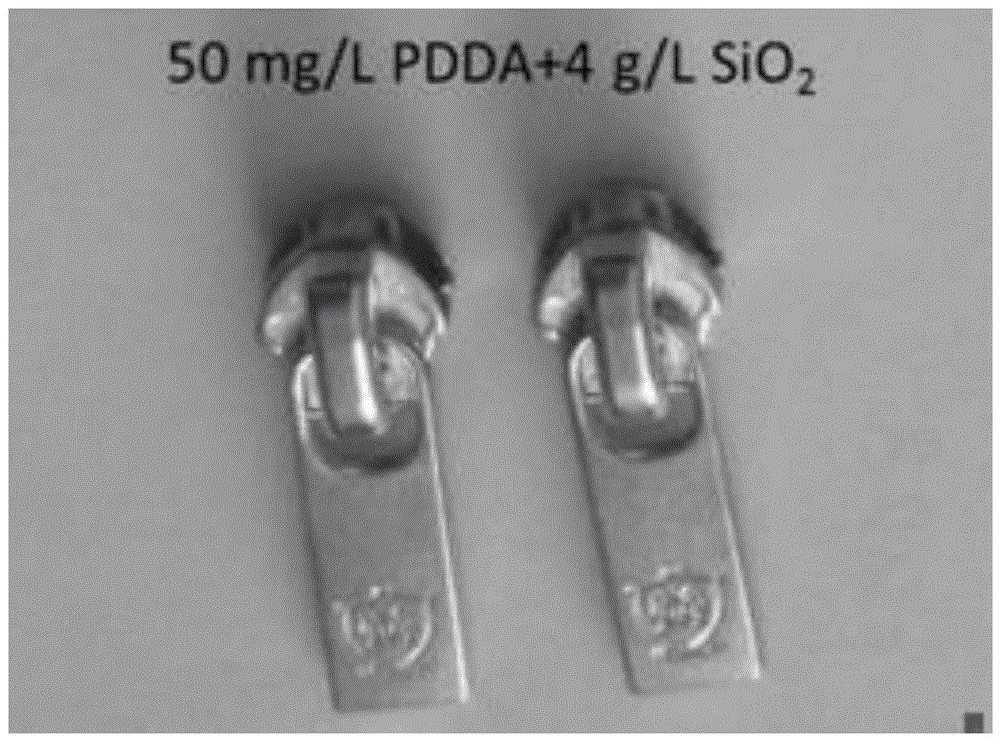

ActiveCN105463534AInhibit growthImprove corrosion resistanceSlide fastenersElectrolytic coatingsPorositySodium potassium tartrate tetrahydrate

The invention provides a nano-composite electroplating solution. The nano-composite electroplating solution is prepared from, by concentration, 23-26 g / L of cuprous cyanide, 10-12 g / L of zinc cyanide, 43-51 g / L of sodium cyanide, 25-35 g / L of sodium carbonate, 10-20 g / L of sodium potassium tartrate tetrahydrate, 4-8 g / L of ammonium chloride, 1-4 g / L of nano SiO2 and the balance water. By adding the nano SiO2, the degree of polarization of the cathode is increased, and growth of Cu-Zn alloy grains is prevented, so that a coating is more refined and compact, the porosity of a deposited layer is decreased, the particle-reinforced metal-based composite coating is formed, and accordingly the corrosion resistance of the coating is improved. It is indicated through test results that the corrosion current of the coating is greatly decreased, and it is proved that the corrosion resistance of the nano-composite coating is obviously improved compared with a Cu-Zn alloy coating. The invention further provides a preparing method of the nano-composite electroplating solution and a zinc alloy electroplated part.

Owner:ZHEJIANG WEIXING IND DEV

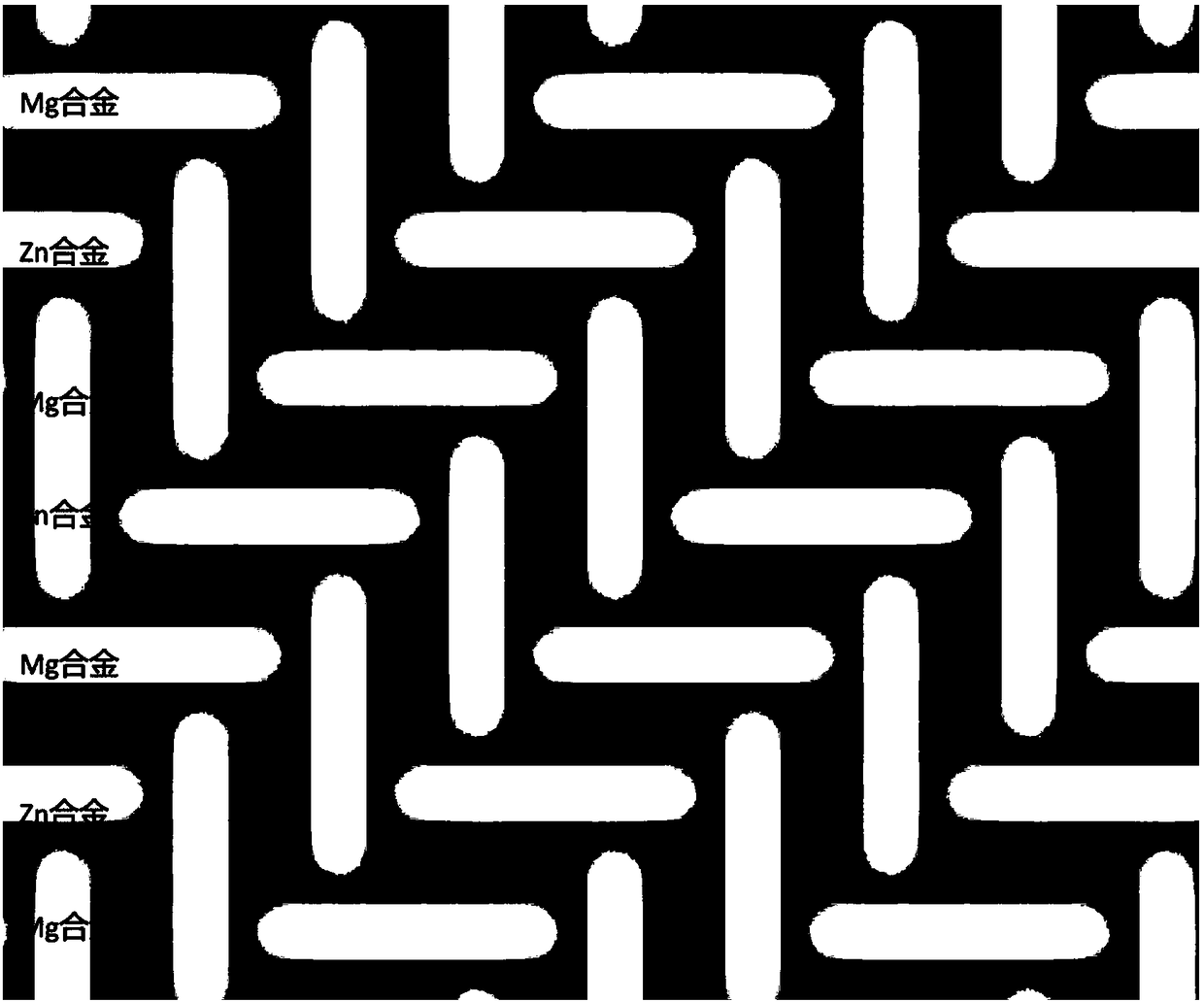

Magnesium alloy and zinc alloy wire hybrid composite sticking patch and application thereof

The invention provides a magnesium alloy and zinc alloy wire hybrid composite sticking patch and application thereof. The magnesium alloy and zinc alloy wire hybrid composite sticking patch is formedthrough mixed weaving of a magnesium alloy wire material and a zinc alloy wire material, and provided with a net structure. The composite sticking patch has the advantage that 1, the sticking patch iscompletely degradable, and absorbed and metabolized by human body in the recovering process from disease, the sticking patch has the good supporting effect in the early implanting stage, and is completely degraded, absorbed and replaced by autologous tissue after tissue recovering is completed in the late stage, and long-term complications caused by a traditional material can be avoided; and 2, by adjusting the size, the appearance and the weaving method of the whole wire material, the composite sticking patches in different types can be obtained, and the sticking patches have different strength and different degradation and absorption time, and can be adaptive to different illness states.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com