Method for preparing nano-sized twin crystal Cu-Al or Cu-Zn alloy

A nano-twin, cu-zn technology is applied in the field of preparation of nano-twin materials, which can solve the problem of high process requirements, achieve the effects of simple preparation process, increase density, and promote deformation twinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The Cu-2.2%Al alloy is processed into a square material of 12.2mm×12.2mm×80mm.

[0030] Carry out solid solution treatment to Cu-2.2%Al alloy, the solution temperature is 800℃, and the holding time is 1.5h. Carrying out solid solution treatment to Cu-Al alloy can play the role of solid solution strengthening. In the subsequent cooling process, First cool the alloy to 500-600°C with the furnace, and then perform brine cooling to make the internal structure of the Cu-Al alloy more uniform.

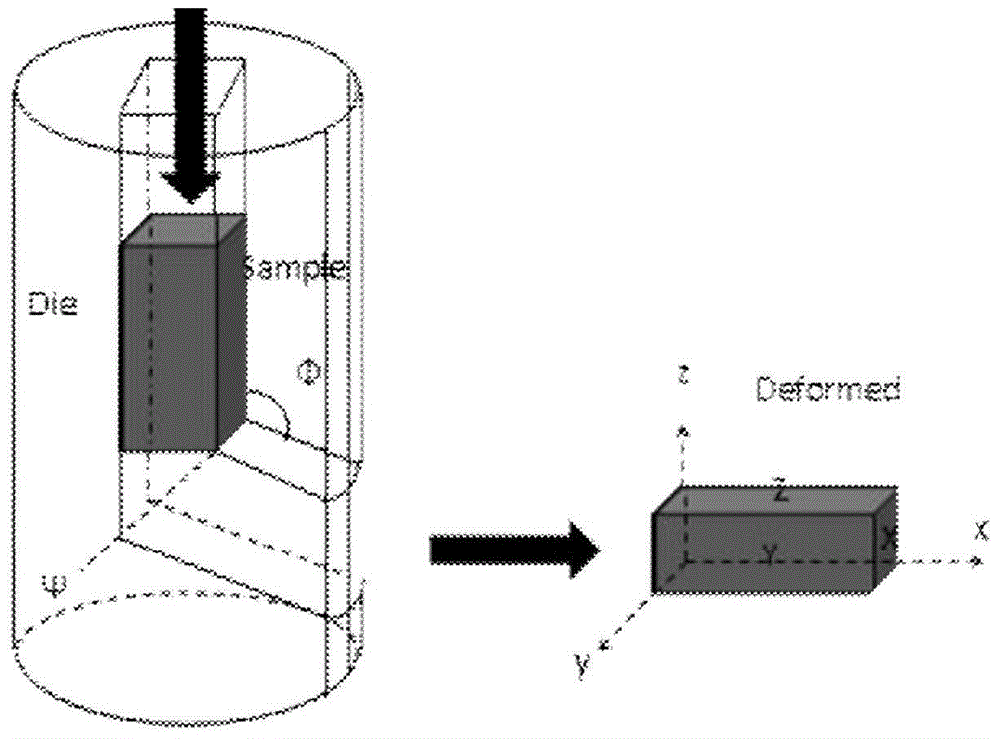

[0031] The Cu-2.2%Al alloy cooled by brine was soaked in liquid nitrogen for 5 minutes, and a secondary equal-channel deformation was carried out quickly, such as figure 1 As shown, the inner corner of the mold undergoing equal channel deformation is 120°, the mold outer angle ψ is 0°, and the deformation speed is 15-60mm / min. The Cu-2.2%Al alloy after equal channel deformation was subjected to cryogenic treatment and soaked in liquid nitrogen for 40min, and the mechanical properti...

Embodiment 2

[0034] The Cu-4.5%Al alloy is processed into a square material of 12.2mm×12.2mm×80mm.

[0035] Carry out solid solution treatment to Cu-4.5%Al alloy, the solution temperature is 900℃, and the holding time is 2h. Carrying out solid solution treatment on Cu-Al alloy can play the role of solid solution strengthening. In the subsequent cooling process, first Cool the alloy to 500-600°C with the furnace, and then perform brine cooling to make the internal structure of the Cu-Al alloy more uniform.

[0036] The Cu-4.5% Al alloy cooled by brine was soaked in liquid nitrogen for 30 minutes, and a secondary equal channel deformation was carried out quickly, and the inner corner of the mold is 120°, the mold outer angle ψ is 0°, and the deformation speed is 15-60mm / min. The Cu-4.5%Al alloy after equal channel deformation was cryogenically treated and soaked in liquid nitrogen for 50 minutes, and the mechanical properties of the material were further optimized by cryogenic treatment. ...

Embodiment 3

[0039] The Cu-7.0%Al alloy is processed into a square material of 12.2mm×12.2mm×80mm.

[0040] Carry out solid solution treatment to Cu-7.0%Al alloy, the solution temperature is 850℃, and the holding time is 1.5h. Carrying out solid solution treatment to Cu-Al alloy can play the role of solid solution strengthening. In the subsequent cooling process, Cool to 500-600°C with the furnace first, and then perform brine cooling to make the internal structure of the Cu-Al alloy more uniform.

[0041] The Cu-7.0% Al alloy cooled by brine was soaked in liquid nitrogen for 15 minutes, and a secondary equal channel deformation was carried out quickly, and the inner corner of the mold is 120°, the mold outer angle ψ is 0°, and the deformation speed is 15-60mm / min. The Cu-7.0%Al alloy after equal channel deformation was cryogenically treated and soaked in liquid nitrogen for 40 minutes, and the mechanical properties of the material were further optimized by cryogenic treatment.

[0042]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com