Preparation method of high-formability aluminum alloy composite board material used for vehicle body external plate

A composite sheet and formability technology, which is applied in the field of preparation of high-formability aluminum alloy composite sheets for body panels, can solve the problems of incomplete crushing, bending performance, adverse effects, etc., and achieve the effect of promoting widespread use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

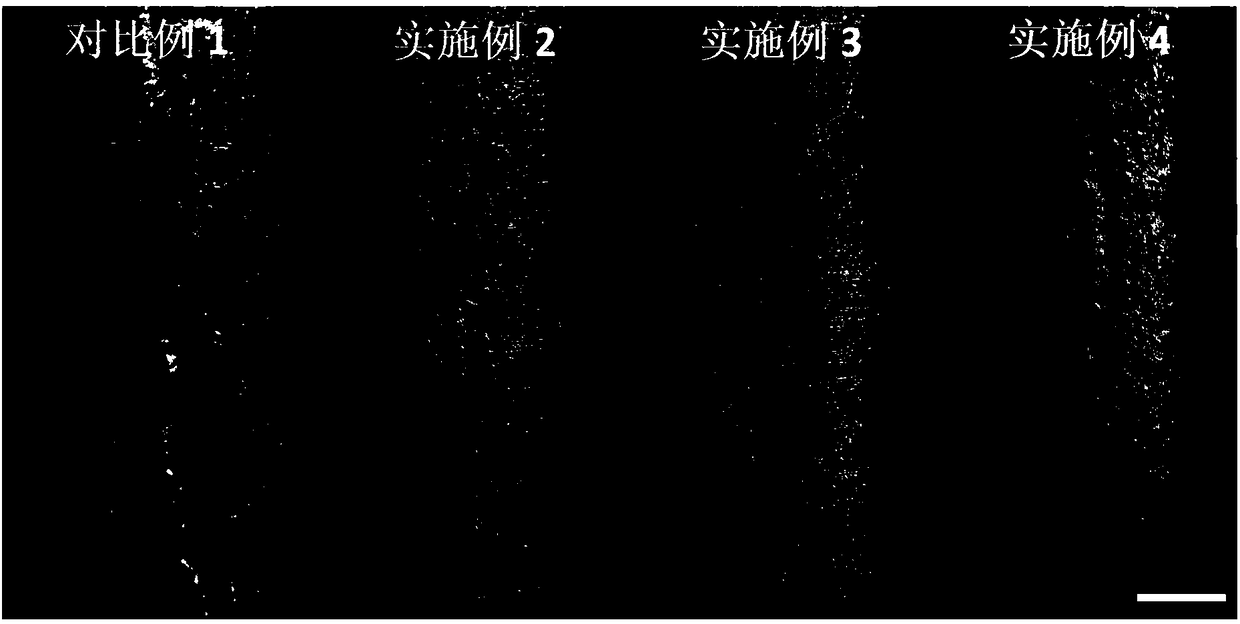

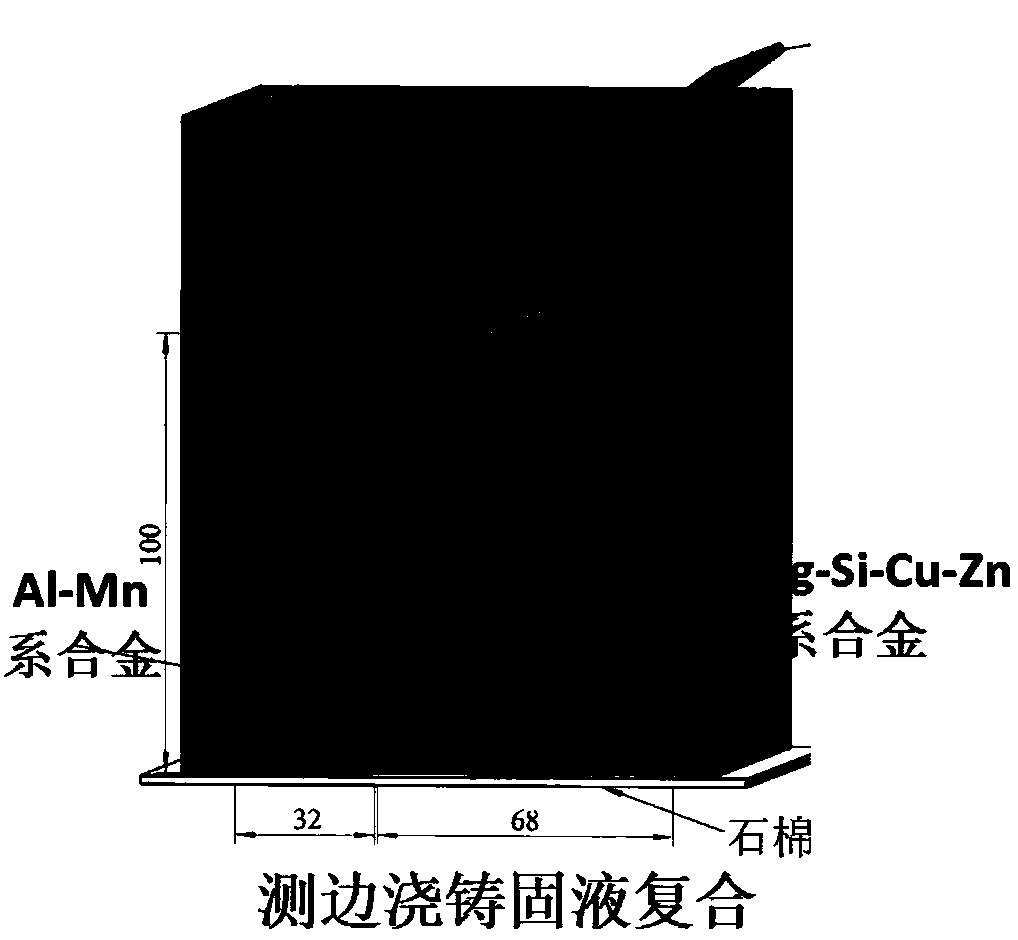

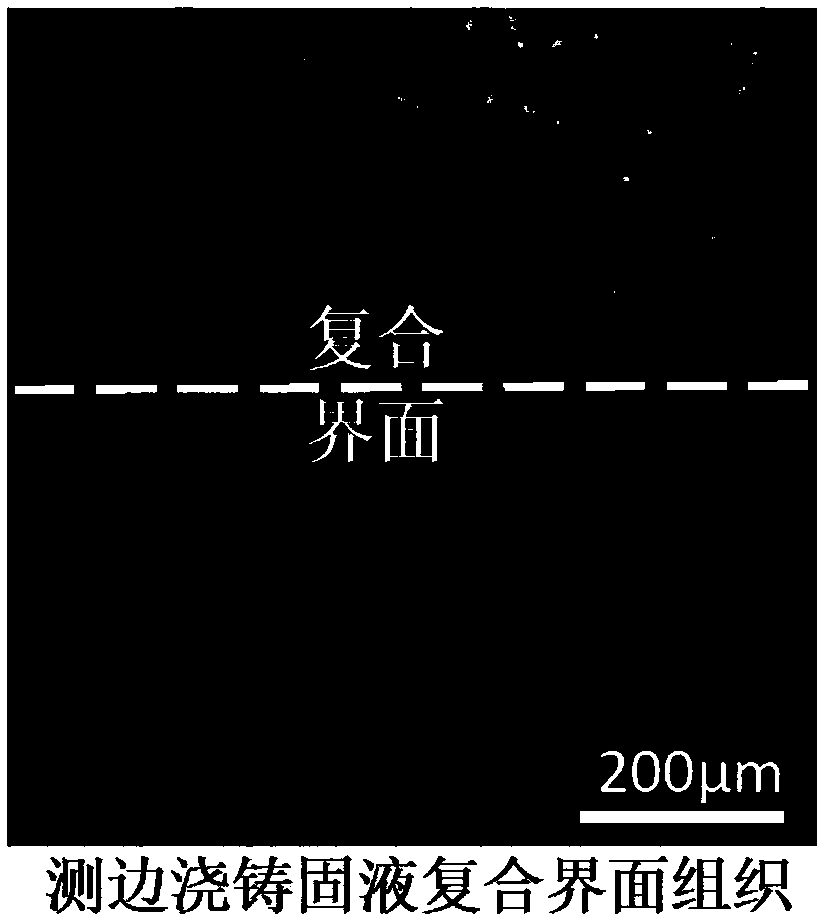

Embodiment 1

[0042] The implementation of aluminum alloy composite plate 1# adopts the following process: firstly, the Al-Mg-Si-Cu-Zn series alloy is smelted by medium frequency induction, the melting method is as follows, all pure aluminum is added to the crucible and the medium frequency induction melting is used, and the temperature is controlled at 780~ 880℃, then add Al-20wt%Si, Al-50wt%Cu, Al-20wt%Fe, Al-10wt%Mn, Al-5wt%Cr, Al-19wt%Ti and other intermediate alloys successively, and use high-power melting After keeping the temperature for 5 minutes, add pure Zn and pure Mg to the melt, and use high power to fully stir to dissolve it thoroughly, and keep it for 5 minutes; continue to wait until the melt is cooled to 740°C, and then remove the slag and add the refining agent for degassing and refining; Then, when the melt temperature is lowered to about 720°C, Al-5wt%Ti-1wt%B grain refiner is added and properly stirred. Finally, the melt is cast into a surrounding water-cooled steel mold ...

Embodiment 2

[0044] The implementation of aluminum alloy composite plate 2# adopts the following process: firstly, the Al-Mg-Si-Cu-Zn series alloy is smelted by medium frequency induction, the melting method is as follows, all pure aluminum is added to the crucible and the medium frequency induction melting is used, and the temperature is controlled at 780~ 880℃, then add Al-20wt%Si, Al-50wt%Cu, Al-20wt%Fe, Al-10wt%Mn, Al-5wt%Cr, Al-19wt%Ti and other intermediate alloys successively, and use high-power melting After keeping the temperature for 5 minutes, add pure Zn and pure Mg to the melt, and use high power to fully stir to dissolve it thoroughly, and keep it for 5 minutes; continue to wait until the melt is cooled to 740°C, and then remove the slag and add the refining agent for degassing and refining; Then, when the melt temperature is lowered to about 720°C, Al-5wt%Ti-1wt%B grain refiner is added and properly stirred. Finally, the melt is cast into a surrounding water-cooled steel mold ...

Embodiment 3

[0046] The implementation of aluminum alloy composite plate 3# adopts the following process: first, the Al-Mg-Si-Cu-Zn series alloy is melted by medium frequency induction, the melting method is as follows, all pure aluminum is added to the crucible and the medium frequency induction melting is used, and the temperature is controlled at 780~ 880℃, then add Al-20wt%Si, Al-50wt%Cu, Al-20wt%Fe, Al-10wt%Mn, Al-5wt%Cr, Al-19wt%Ti and other intermediate alloys successively, and use high-power melting After keeping the temperature for 5 minutes, add pure Zn and pure Mg to the melt, and use high power to fully stir to dissolve it thoroughly, and keep it for 5 minutes; continue to wait until the melt is cooled to 740°C, and then remove the slag and add the refining agent for degassing and refining; Then, when the melt temperature is lowered to about 720°C, Al-5wt%Ti-1wt%B grain refiner is added and properly stirred. Finally, the melt is cast into a surrounding water-cooled steel mold aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com