Magnesium alloy and zinc alloy wire hybrid composite sticking patch and application thereof

A technology of magnesium alloy and zinc alloy, which is applied in the field of mixed composite patch of magnesium alloy and zinc alloy wire, can solve the problems of partial eclipse or even different eclipse, decreased taste, etc., and achieve the effect of improving the degradation speed and avoiding long-term complications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] Since the preparation methods of magnesium alloy wire and zinc alloy wire in the present invention are the same, the preparation methods of magnesium alloy wire and zinc alloy wire can be introduced only by taking magnesium alloy wire as an example, which mainly includes the following steps: turning a certain height Cylindrical wire-extruding blanks; hot-extruding cylindrical-shaped wire-extruding blanks at a certain temperature to obtain magnesium alloy and zinc alloy wire blanks with a diameter of φ1~2mm; multi-pass drawing of wire blanks , Rolling deformation and auxiliary heat treatment can obtain fine wires with different wire diameters.

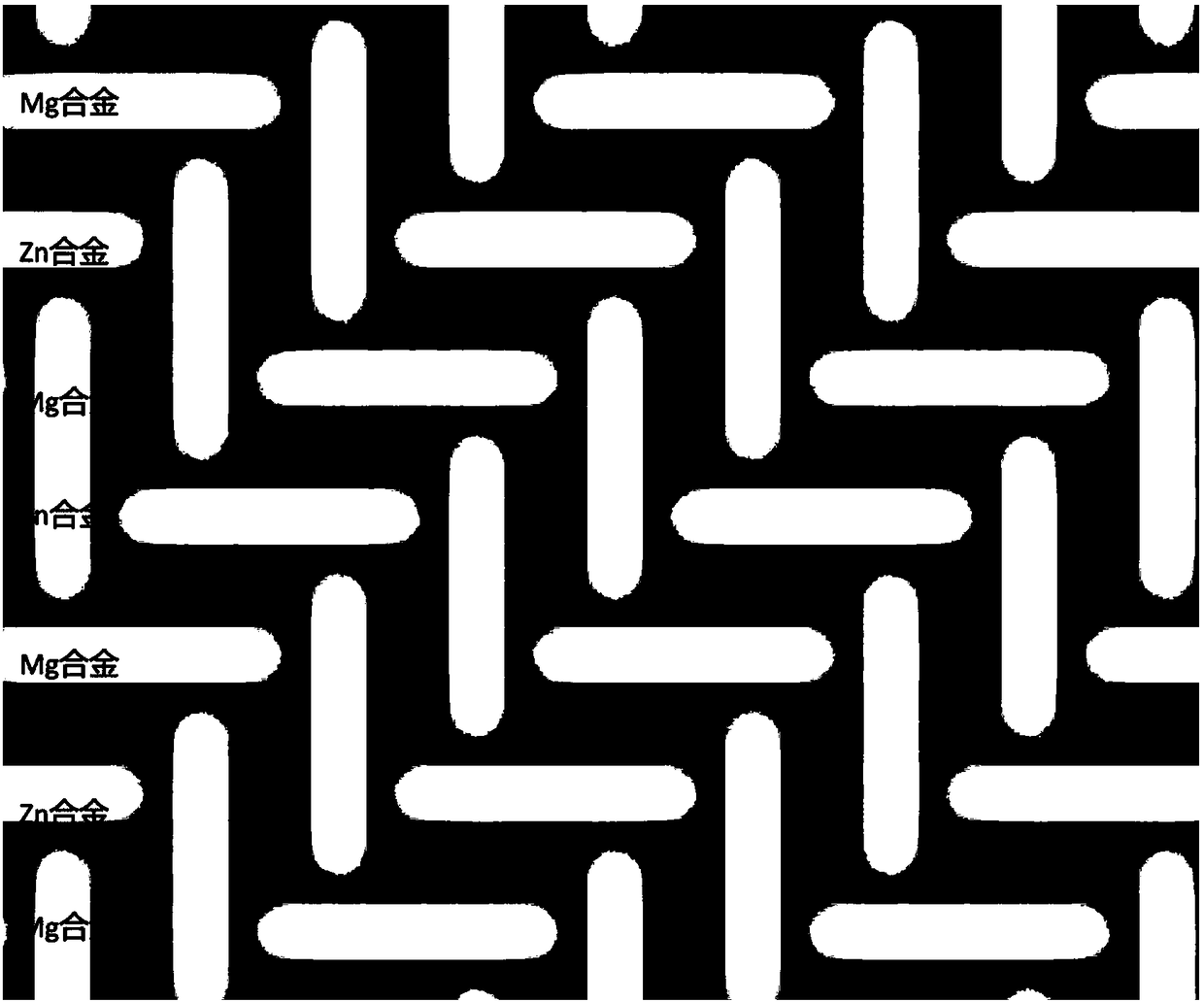

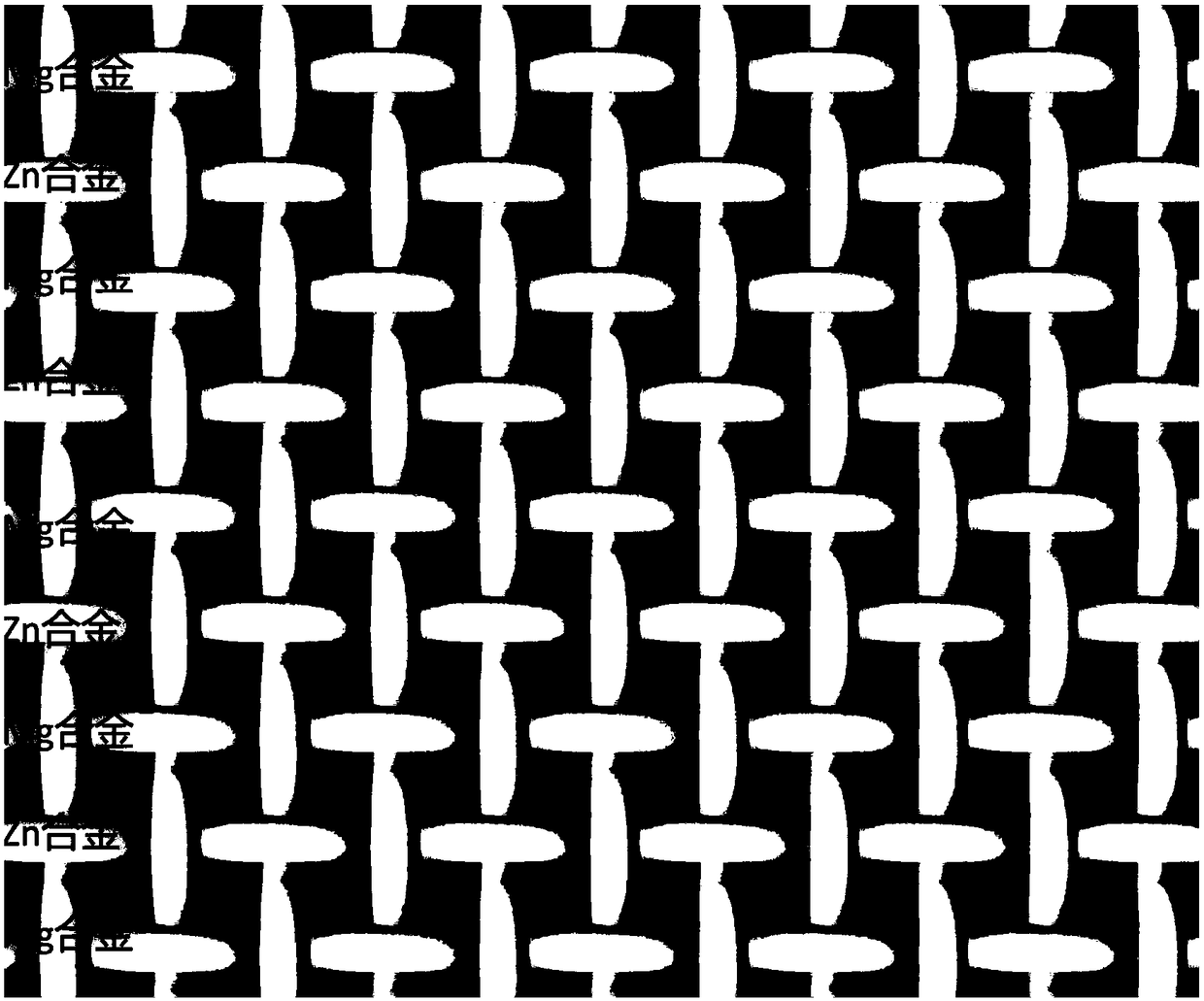

[0027] The morphology of the biodegradable mixed weaving composite patch prepared in the present invention can be as follows figure 1 As shown, it can also be figure 2 shown.

Embodiment 1

[0029] 1) The Mg-Zn-Zr alloy thin wire with a circular diameter of 0.05 mm and the Zn-Cu alloy thin wire with a diameter of 0.05 mm prepared by the above method are braided into a thin rope (such as 2 strands) on a braiding machine. Magnesium wire and 1 strand of zinc wire are woven into a thin rope), and then the aforementioned thin rope is woven into a net, and the size of the net can be cut arbitrarily.

[0030] 2) After electrolytic polishing, cleaning, drying, packaging and sterilization, it is ready for use.

[0031] The thickness of the final product is 0.1mm, and the area of a single mesh is 0.1mm 2 .

Embodiment 2

[0033] 1) Mg-Zn-Gd-based alloy filaments with an elliptical cross-section, a major axis of 0.05 mm and a short axis of 0.04 mm and Zn- The Fe alloy wires are woven into nets on the knitting machine, which can be cut arbitrarily.

[0034] 2) After electropolishing and cleaning.

[0035] 3) Degradable coating treatment.

[0036] 4) Dry, package, and sterilize before use.

[0037] The thickness of the final product is 0.2mm, and the area of a single mesh is 1mm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

| Cross-sectional area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com