Degradable soft tissue patch

A patch and soft tissue technology, applied in the field of biodegradable artificial organs, can solve the problems of increasing the chance of infection of implanted materials, poor flexibility and restrictions of polyglactin, and achieve the effect of avoiding long-term complications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

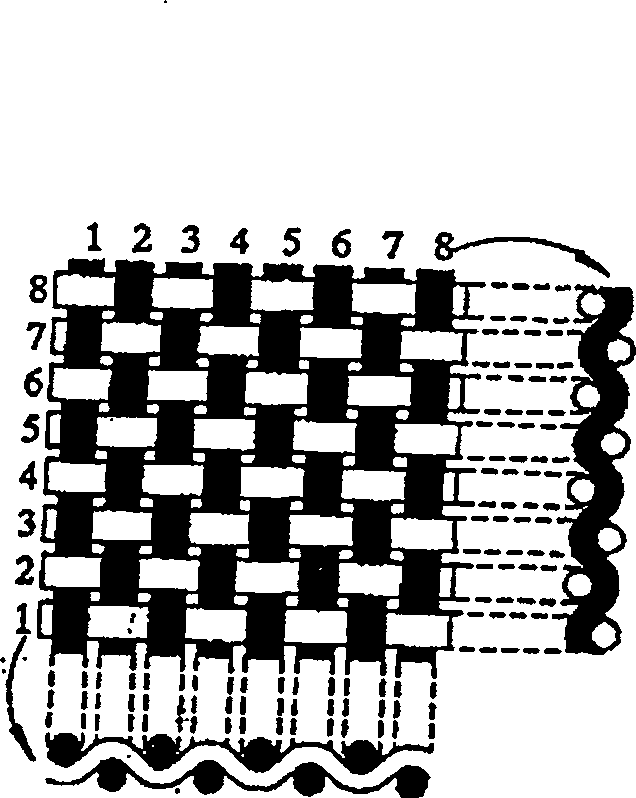

[0013] Polydioxanone monofilament fibers with a diameter of 0.28mm were woven on a sample loom by plain weaving method, warp density: 320 threads / 10cm, weft density: 230 threads / 10cm. The warp tightness of the obtained fabric: 89.6%, weft tightness: 64.4%, thickness 0.8mm, mesh gap 200-300μm; then heat-press it at 90°C for 5 seconds; then soak it in 2% collagen After 3 minutes in the solution, take it out, put it in a 40°C oven to dry, repeat the above operation twice; then use 2.0% chitosan coating agent to coat the mesh wall facing the viscera, and dry it in a 40°C oven to set the shape. Repeat the above operation twice to obtain a complete patch material whose inner layer is a mesh support and the surface layer is a coating material, which is sterilized by ethylene oxide, vacuum-dried, sealed and stored at 4°C.

Embodiment 2

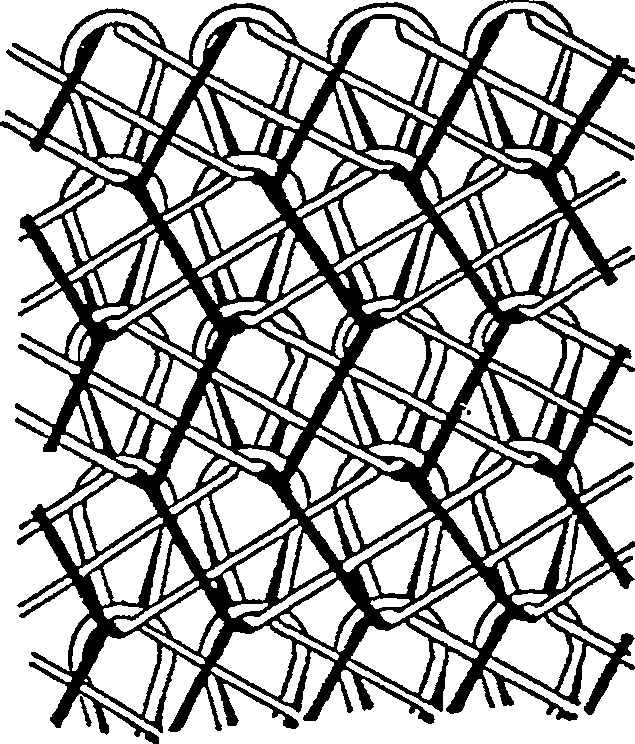

[0015] Polydioxanone monofilament fibers with a diameter of 0.20mm are woven into a net on a warp knitting machine with a gauge number of 14-18 needles, and the organizational structure is a warp pile (such as figure 2 ) tissue, the vertical density is 55 / 5cm, and the horizontal density is 32 / 5cm. The obtained fabric has a porosity of 72%, a thickness of 0.65 mm, can be cut arbitrarily, and the edges do not fall apart. Then soak it in 2% collagen solution for 3 minutes, take it out, put it in a 40°C oven to dry, repeat the above operation twice; then apply 2.0% chitosan coating agent to the mesh wall facing the viscera, It was dried and shaped in an oven at 40°C, and the above operation was repeated twice. After being sterilized by ethylene oxide, it was vacuum-dried and sealed at 4°C for storage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com