Magnesium alloy and polymer wire mixed braided composite patch and its application

A magnesium alloy and polymer technology, which is applied in the field of magnesium alloy and polymer wire mixed composite patch, can solve the problems of non-degradable, partially degradable, increased wounds, etc., and achieve the effect of avoiding long-term complications and stabilizing pH

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the magnesium alloy wire in the present invention is: turning the cylindrical blank for wire extrusion of a certain height; performing hot extrusion on the cylindrical blank for wire extrusion at a certain temperature to obtain a wire blank with a diameter of φ1-2mm ;Thin wires with different wire diameters can be obtained by multi-pass drawing, rolling deformation and auxiliary heat treatment on the wire blank. The preparation method of the polymer filament is as follows: the absorbable polymer (polylactic acid, polycaprolactone, collagen) is melted and extruded to prepare the polymer filament.

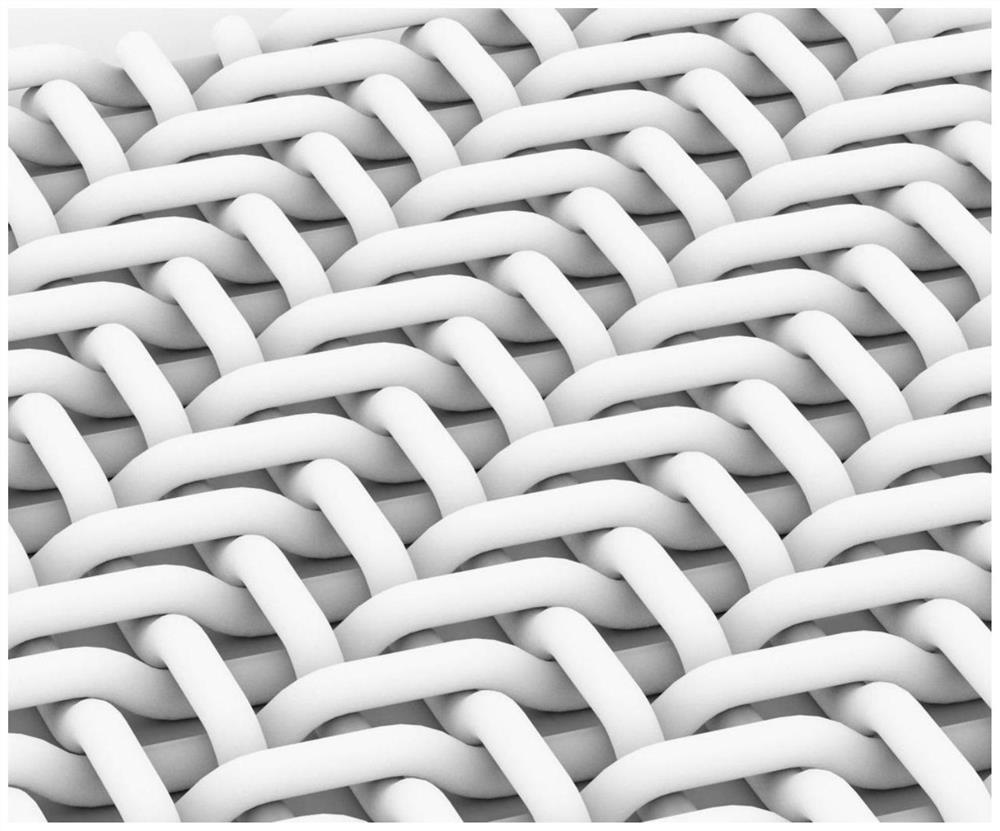

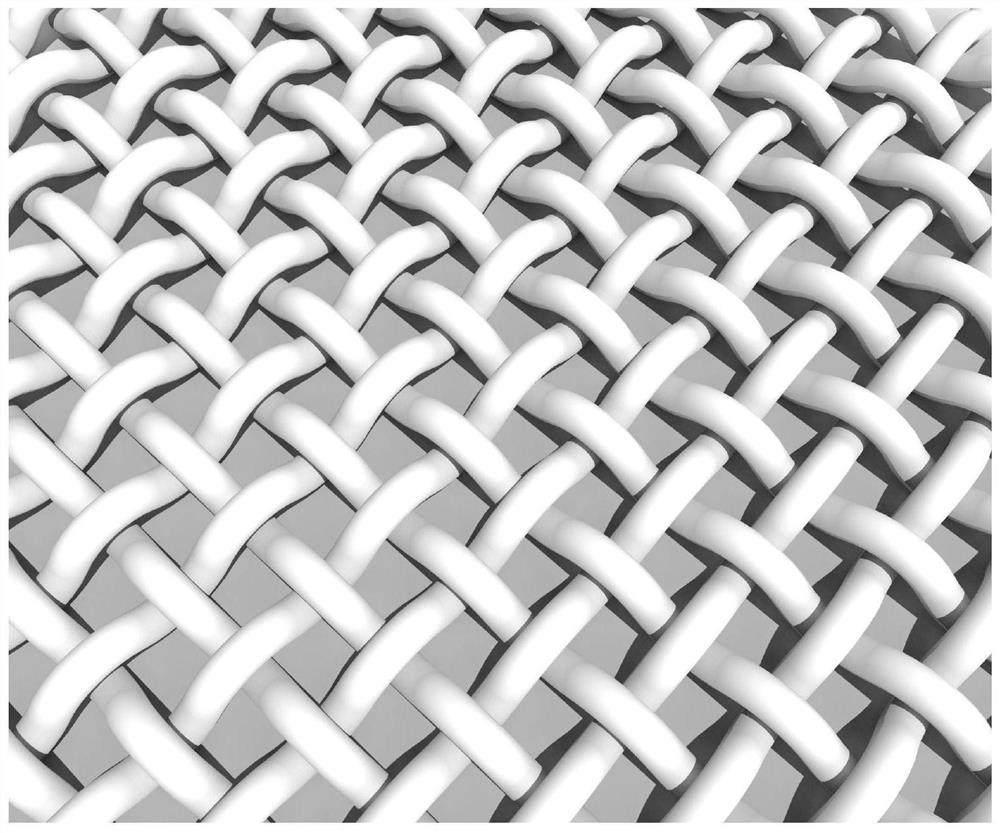

[0028] The morphology of the biodegradable mixed weaving composite patch prepared in the present invention can be as follows figure 1 As shown, it can also be figure 2 shown.

Embodiment 1

[0030] 1) The Mg-Zn-Zr alloy thin wire with a circular cross-section and a diameter of 0.05 mm prepared by the above method and the polylactic acid polymer wire with a diameter of 0.05 mm are braided into a thin rope on a braiding machine, and then used The rope is woven into a net, and the size of the net can be cut arbitrarily.

[0031] 2) After electrolytic polishing, cleaning, drying, packaging and sterilization, it is ready for use.

[0032] The thickness of the final product is 0.1mm, and the area of a single mesh is 0.1mm 2 .

Embodiment 2

[0034] 1) Mg-Zn-Gd-based alloy filaments with an elliptical cross-section, a major axis of 0.05 mm and a minor axis of 0.04 mm and a circular cross-section with a diameter of 0.1 mm were prepared by the above method. The polycaprolactone polymer thread is woven into a net on the knitting machine, which can be cut arbitrarily.

[0035] 2) After electropolishing and cleaning.

[0036] 3) Degradable coating treatment.

[0037] 4) Dry, package, and sterilize before use.

[0038] The thickness of the final product is 0.2mm, and the area of a single mesh is 1mm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com