Nano level sheet copper zinc alloy powder and its producing method

A nano-scale and alloy powder technology is applied in the field of nano-scale flake copper-zinc alloy powder and its manufacturing, which can solve the problems of large powder thickness, uneven powder thickness distribution, difficulty in preparing thickness powder flakes, etc., and achieve the effect of uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

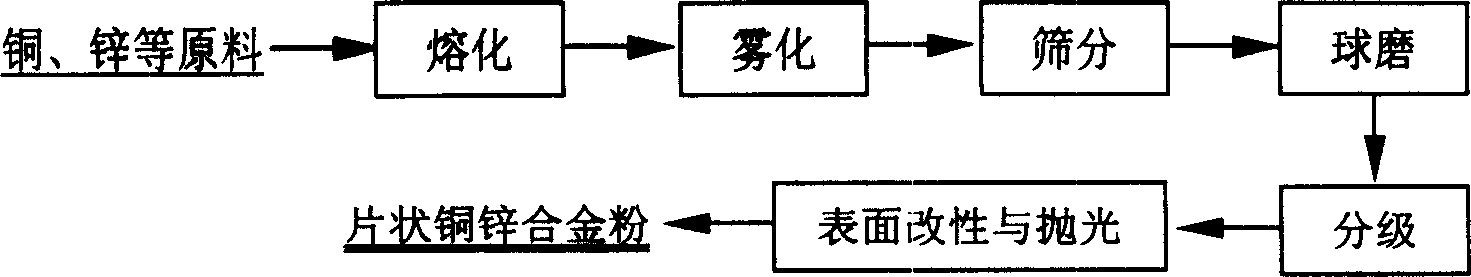

Method used

Image

Examples

Embodiment Construction

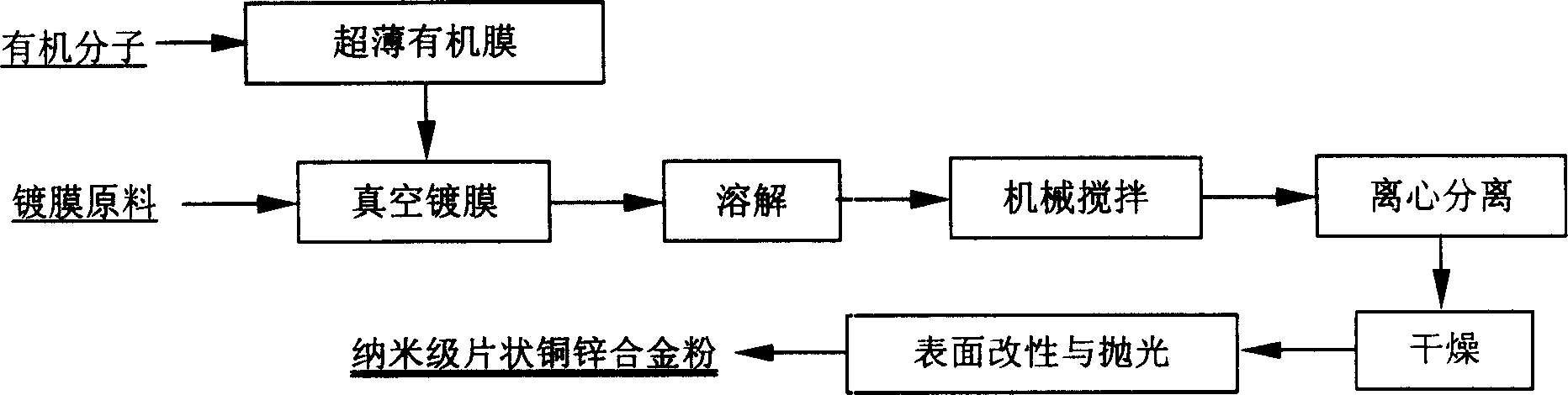

[0021] 1. Vacuum evaporation coating-crushing process to prepare nano-scale flake copper-zinc alloy powder

[0022] Thin copper rods, thin zinc rods and thin aluminum rods with a purity of 99.7% are added to the tantalum boat at the ratio of 91.1% copper, 7.9% zinc, and 1.0% aluminum for evaporation coating.

[0023] The analytical pure collodion with a nitrocellulose content greater than 5% is diluted with chemically pure n-pentyl acetate (content greater than 98.5%) to reduce the collodion content to 2%. Pour the collodion dilute solution into water, and a collodion film can be formed above the water surface. Dry the collodion film in a vacuum oven, or in an ordinary drying oven at about 50°C.

[0024] Put the prepared base film (i.e. collodion film) into the evaporation coating machine, then vacuumize, when the pressure drops to 20Pa, feed argon gas, and after the pressure drops to 10-3Pa and stabilizes for 20 minutes, the Coating can be evaporated. The current is 40A, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com