Silver-based solder paste and preparation method thereof

A brazing paste, silver-based technology, used in welding equipment, welding media, manufacturing tools, etc., can solve the problems of unstable product quality, environmental pollution, diamond layer burning, etc., to improve efficiency, simplify production processes, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

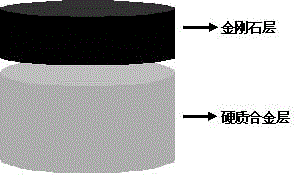

[0012] The invention relates to a silver-based brazing paste and a preparation method thereof. The silver-based brazing paste is composed of: 75% to 80% of Ag-Cu-Zn alloy solder powder, silver fluoride Flux powder 10%~14%, saturated sodium silicate aqueous solution 7%~8%, white oil 2%~3%, alkylphenol polyoxyethylene ether 1%~2%.

[0013] The above-mentioned silver-based brazing paste, in terms of mass percentage, its optimal components are: Ag-Cu-Zn alloy solder powder 76%, fluoride silver solder powder 12%, saturated sodium silicate aqueous solution 7.5% , white oil 3%, alkylphenol polyoxyethylene ether 1.5%.

[0014] The preparation method of silver-based brazing paste is prepared by the above-mentioned components, and its steps are:

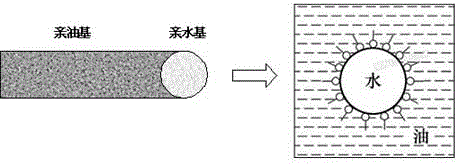

[0015] (1) By grinding or atomizing, the Ag-based solder ingot, Ag: Cu: Zn ≈ 40%: 40%: 20%, is made into a powder of about 200 mesh; then, select 75%~ 80% solder powder and 10%~14% fluoride silver solder powder are stirred with a glass rod t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com