High-service-life marble cutter head blank body and manufacturing method of cutter head

A production method and marble technology, which is applied to other manufacturing equipment/tools, engine components, turbines, etc., can solve the problems of slow diamond exposure, reduced versatility of diamond cutter heads, and low wear resistance, so as to improve service life and strengthen The effect of versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

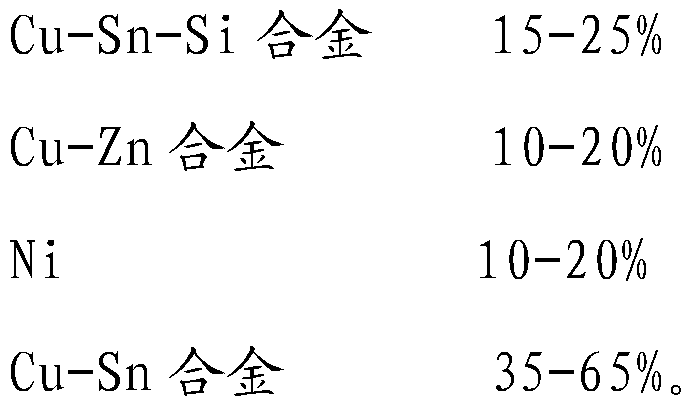

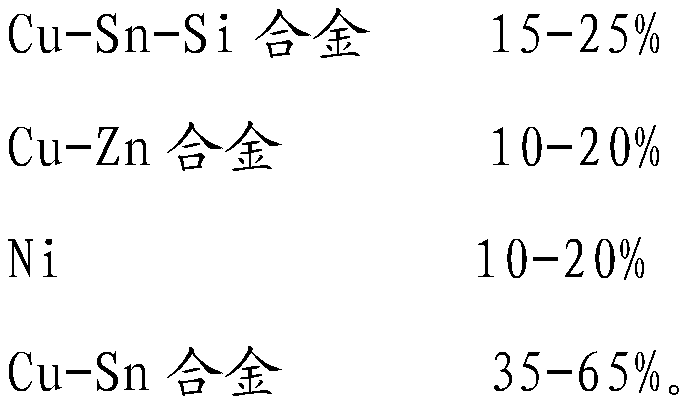

[0031] Specific embodiment 1, a kind of high-life marble cutter carcass, formula composition is made up of following percentage by weight: Cu-Sn-Si alloy 18%; Cu-Zn alloy 12%; Ni 12%; Cu-Sn alloy 58%.

specific Embodiment 2

[0032] Specific embodiment 2, a long-life marble cutter head carcass, the formula components are composed of the following weight percentages: Cu-Sn-Si alloy 25%; Cu-Zn alloy 15%; Ni 15%; Cu-Sn alloy 45%.

[0033] Carcass formula feature of the present invention is set forth below:

[0034] 1. Cu-Sn-Si alloy is a new type of high brittle powder. The addition of non-metallic Si increases the brittleness of the matrix, which can increase the height of the diamond edge and improve the sharpness of the product.

[0035] 2. The low-melting point elements Sn and Zn in the formula are added in the form of alloys. During sintering, the sintering range is wider, which can effectively control the loss of low melting point. The low melting point in the carcass is added in an alloy form and the carcass Ni is added together, which can relax the requirements for welding materials, and can use welding materials with lower silver content for welding, which can reduce welding costs.

[0036] ...

Embodiment 1

[0053] A method for making a high-life marble cutter head, the steps are as follows:

[0054] 1) The carcass powder material is weighed according to the proportion, and stirred for 60 minutes with a three-dimensional mixer; the formula components of the carcass powder material are composed of the following weight percentages: Cu-Sn-Si alloy 18%; Cu-Zn alloy 12%; Ni12 %; Cu-Sn alloy 58%;

[0055]2) Use copper-coated diamonds with a content of 50% in 60 / 70 and 50% in 70 / 80, mix them thoroughly with a splitter, then add 3‰ of paraffin into the diamond, and mix by hand for 3 minutes;

[0056] 3) Mix 98% of the carcass powder and 2% of the diamond by weight, and mix them in a mixer for 45 minutes to obtain a compound of the carcass and the diamond;

[0057] 4) In the multi-layer automatic cold pressing machine, the mixture is pressed into a cutter body, and the cold pressing pressure is 1000kg / cm2.

[0058] 5) Put the green body into a multi-layer graphite mold and carry out sint...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com