Cu-zn alloy with high strength and excellent bendability

A bending workability, high-strength technology, used in metal layered products, layered products, chemical instruments and methods, etc., can solve the problems of cost reduction and high price, and achieve excellent bending workability, excellent bending workability, The effect of high-strength bending workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

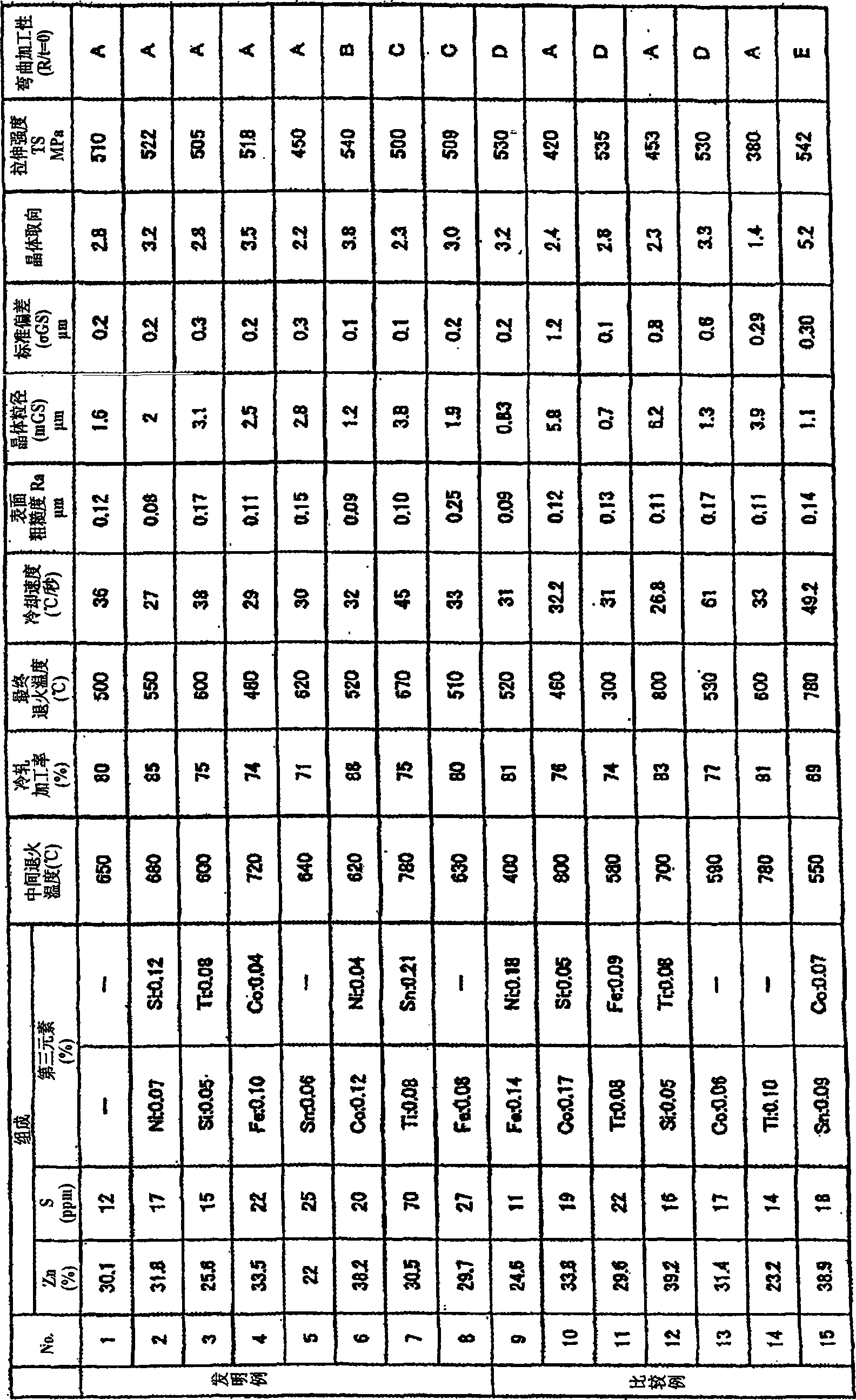

[0047] The copper alloy with the composition shown in Table 1 was melted in a low-frequency induction furnace, and then cast into a mold with a thickness of 180 mm by a vertical continuous casting method to make an ingot. Then hot rolled to 9mm. Thereafter, cold rolling with a cold working ratio of 83% was performed to a thickness of 1.5 mm, followed by annealing, cold rolling, and final annealing. The preparation conditions of each step are shown in Table 1 as Example 1.

[0048] The measurement methods of the relevant characteristic values of the present invention are as follows.

[0049] (a) Tensile strength (TS: MPa) and 0.2% proof stress (YS: MPa) were obtained by taking a No. 13B test piece (JIS Z 2201) parallel to the rolling direction and performing a tensile test (JIS Z 2241).

[0050] (b) The crystal grain size is the number of crystal grains that are completely cut off by a line segment of a specified length by the cutting method (JIS H 0501), and the average va...

Embodiment 2

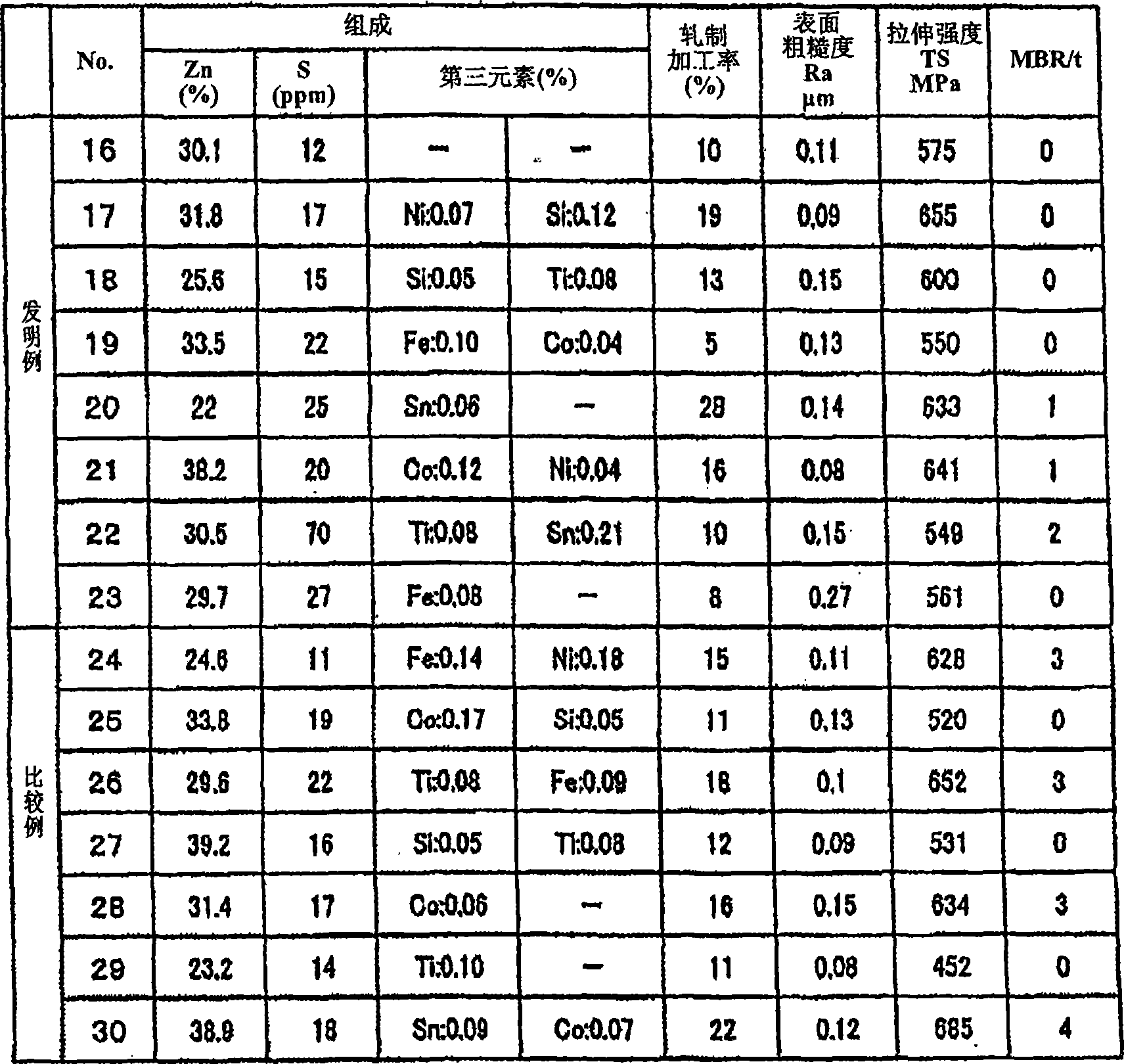

[0063] In Example 2, the final annealed materials of Example 1 were subjected to final rolling at a processing rate of 0-40%. For example, the embodiment in which the final cold rolling was performed on the material (annealed) of Invention Example 1 is Invention Example 16 (rolled), and the embodiment in which the final cold rolling was performed on the material (annealed) in Comparative Example 9 is comparative Example 24 (finished rolling). The same applies to Inventive Examples 17-23 and Comparative Examples 25-30. The preparation conditions are shown in Table 2, and the results of the effects of Example 2 are shown in Table 2.

[0064] [Table 2]

[0065]

[0066] In Invention Examples 16-23, the relational expression {I(220)+I(111)} / I(200) is within the range satisfying claim 2 or claim 4, so a Cu-Zn alloy having high strength and excellent bending workability can be obtained.

[0067]In Comparative Examples 24 and 26, the average crystal grain size before the fina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com