Method for manufacturing automobile casing with design on surface

A production method and pattern technology, which can be applied to car bodies, vehicle parts, and active visual advertisements, etc., can solve the problems that patterns or characters are easy to fade or fade, the production process is particularly strict, and the varnish on the surface of the car falls off. Propaganda is clear and elegant, with low production cost and clear lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

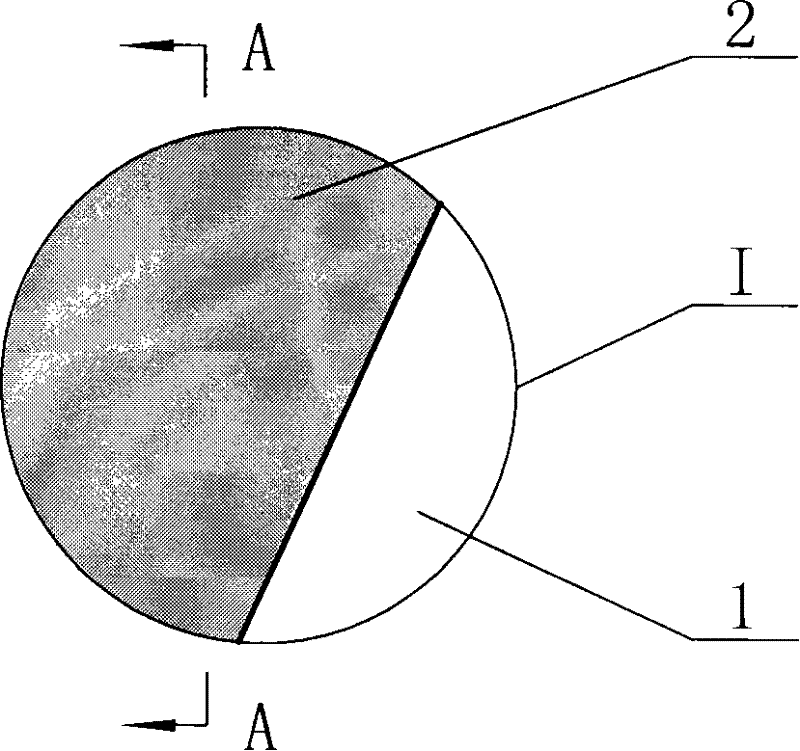

[0011] The present invention will be further described with reference to the accompanying drawings.

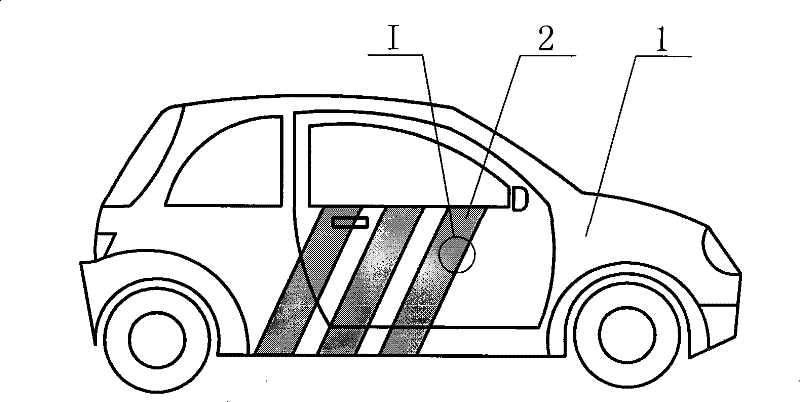

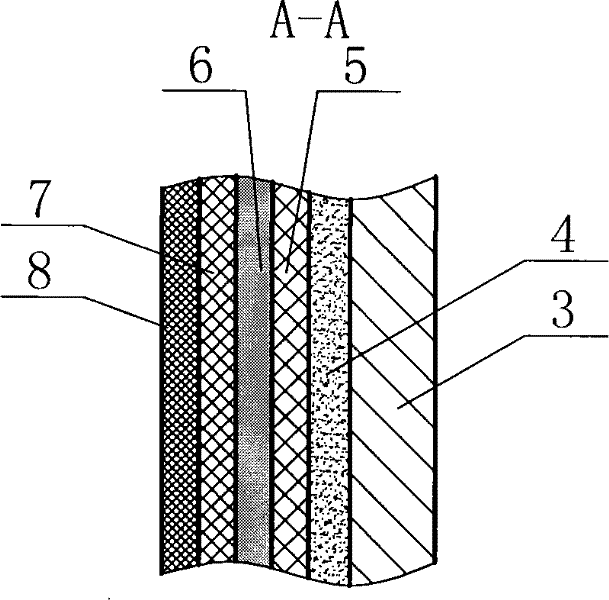

[0012] A kind of car shell that the surface of the present invention is provided with patterns, car shell 1 is made by metal material, and the cross-sectional structure of car shell 1 has metal layer 3, and the upper surface on the metal layer 3 is putty layer 4, and the putty layer 4 The upper surface is a primer layer 5, the upper surface of the primer layer 5 is a patterned paint layer 6, the paint layer 6 upper surface is a varnish layer 7, and the varnish layer 7 upper surface is a bright paint layer 8.

[0013] A method for making a car body with a pattern on the surface of the present invention comprises the following steps: making a metal case according to the shape of the car body; then evenly applying putty on the metal surface to form a putty layer; polishing the putty after drying Spray the primer on the surface evenly to form a primer layer; polish the dry primer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com