Concrete curing agent and preparation method thereof

A technology of concrete curing agent and paraffin wax, which is applied in the field of building material additives. It can solve the problems of difficult removal of film, low water retention rate, and short curing time, and achieve good decorative effect, significant water retention rate and long curing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Concrete curing agent, the components are proportioned as follows by weight: paraffin 8Kg, sorbitan monofatty acid ester 1Kg, triethanolamine 1Kg, stearic acid 0.5Kg, glycerol monostearate 0.5Kg, ethylene glycol monostearate Fat 0.5Kg, water 50Kg.

[0021] The preparation method of the concrete curing agent: take the paraffin wax, sorbitan monofatty acid ester, triethanolamine, stearic acid, glycerol monostearate and pearl flakes of the above weight in a reaction kettle and heat them to melt completely, then add dropwise Warm water at 50-60°C, add dropwise and stir until it becomes a milky white liquid to get this concrete curing agent.

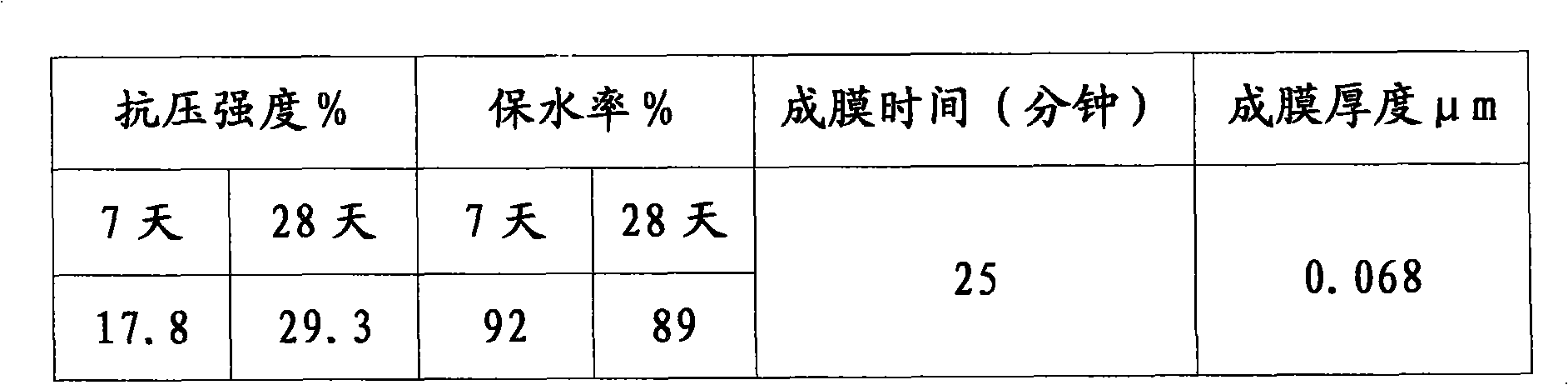

[0022] Dilute the curing agent made according to the above ratio by 8m 2 / kg sprayed on the surface of the test piece, the measured data are as follows:

[0023]

Embodiment 2

[0025] In the present embodiment, each component is proportioned by weight: paraffin wax 10g, sorbitan monofatty acid ester 2Kg, triethanolamine 2Kg, stearic acid 1Kg, glycerol monostearate 1Kg, stearic acid ethylene glycol double fat 1Kg , 60Kg of water.

[0026] The preparation method is the same as in Example 1.

Embodiment 3

[0028] In the present embodiment, each component is proportioned by weight: 12Kg of paraffin wax, 3Kg of sorbitan monofatty acid ester, 3Kg of triethanolamine, 1.5Kg of stearic acid, 1.5Kg of glycerol monostearate, ethylene glycol monostearate Fat 1.5Kg, water 70Kg.

[0029] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com