Power transport mechanism and plasma auxiliary chemical vapor deposition apparatus using the same

A chemical vapor deposition, power transmission technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of reducing the qualified rate, large floor space, high cost, and achieve the effect of improving competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] In order to enable a further cognition and understanding of the features, purposes and functions of the present invention, the related detailed structure and design concept of the device of the present invention are described below:

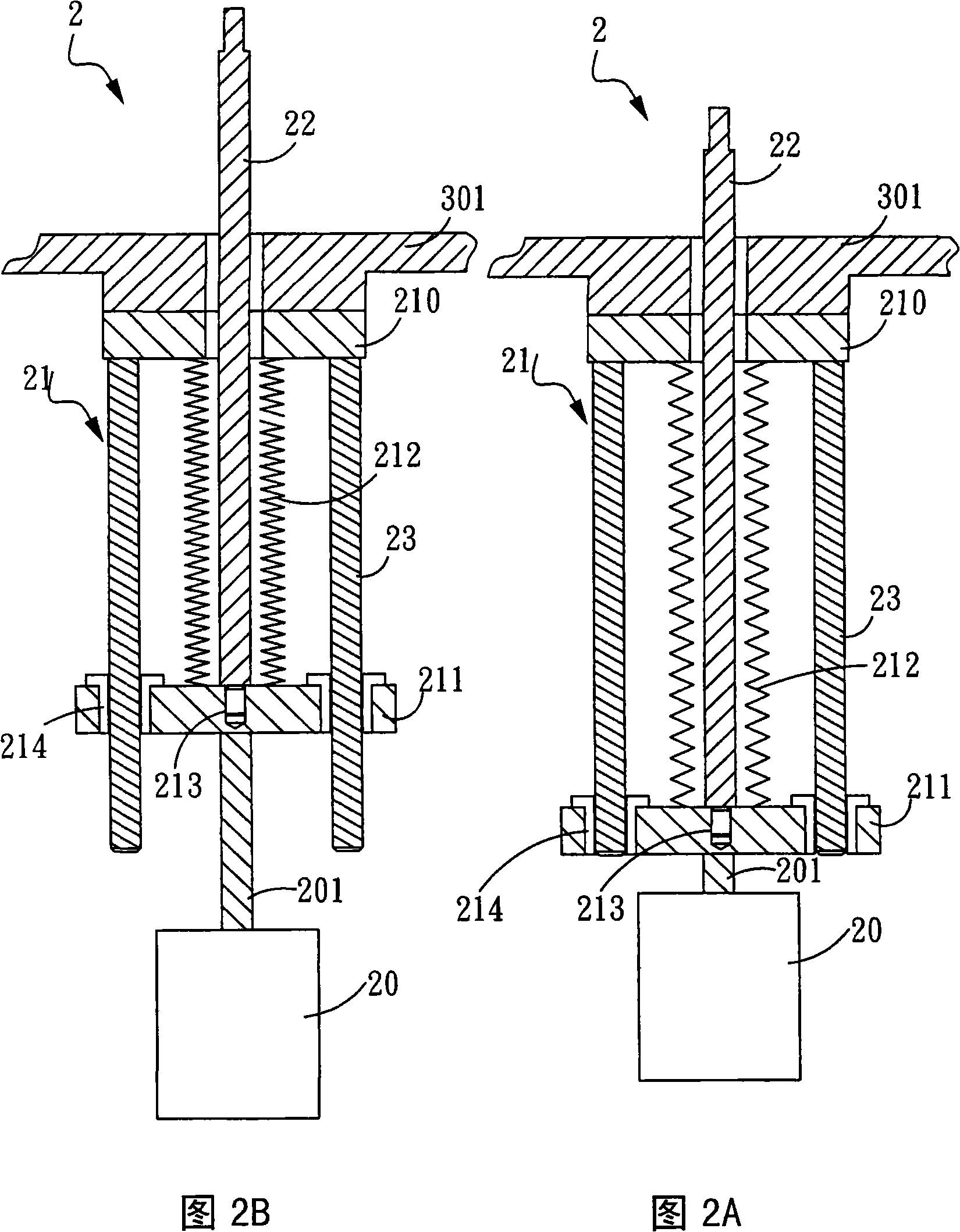

[0083] Refer to FIG. 2A and FIG. 2B, which are schematic cross-sectional views of an embodiment of the power transmission mechanism of the present invention. As shown in FIG. 2A, the power transmission mechanism 2 includes a power unit 20, an airtight telescopic unit 21 and a supporting column 22. The power unit 20 can provide power, and the power unit 20 can be a pneumatic cylinder, a motor, or other components with power output capabilities. In this embodiment, the power unit 20 is a pneumatic cylinder. The airtight telescopic unit 21 is connected to the power unit 20 to receive the power provided by the power unit 20. The support column 22 is disposed in the airtight telescopic unit 21, and one end of the support column 22 extends to the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com