Cantilever elevation scaffold

A technology for lifting scaffolding and cantilever, applied in the field of scaffolding, can solve the problems of material and time-consuming, building damage, insecurity, etc., and achieve the effects of improving economic efficiency, reducing labor intensity, and improving safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

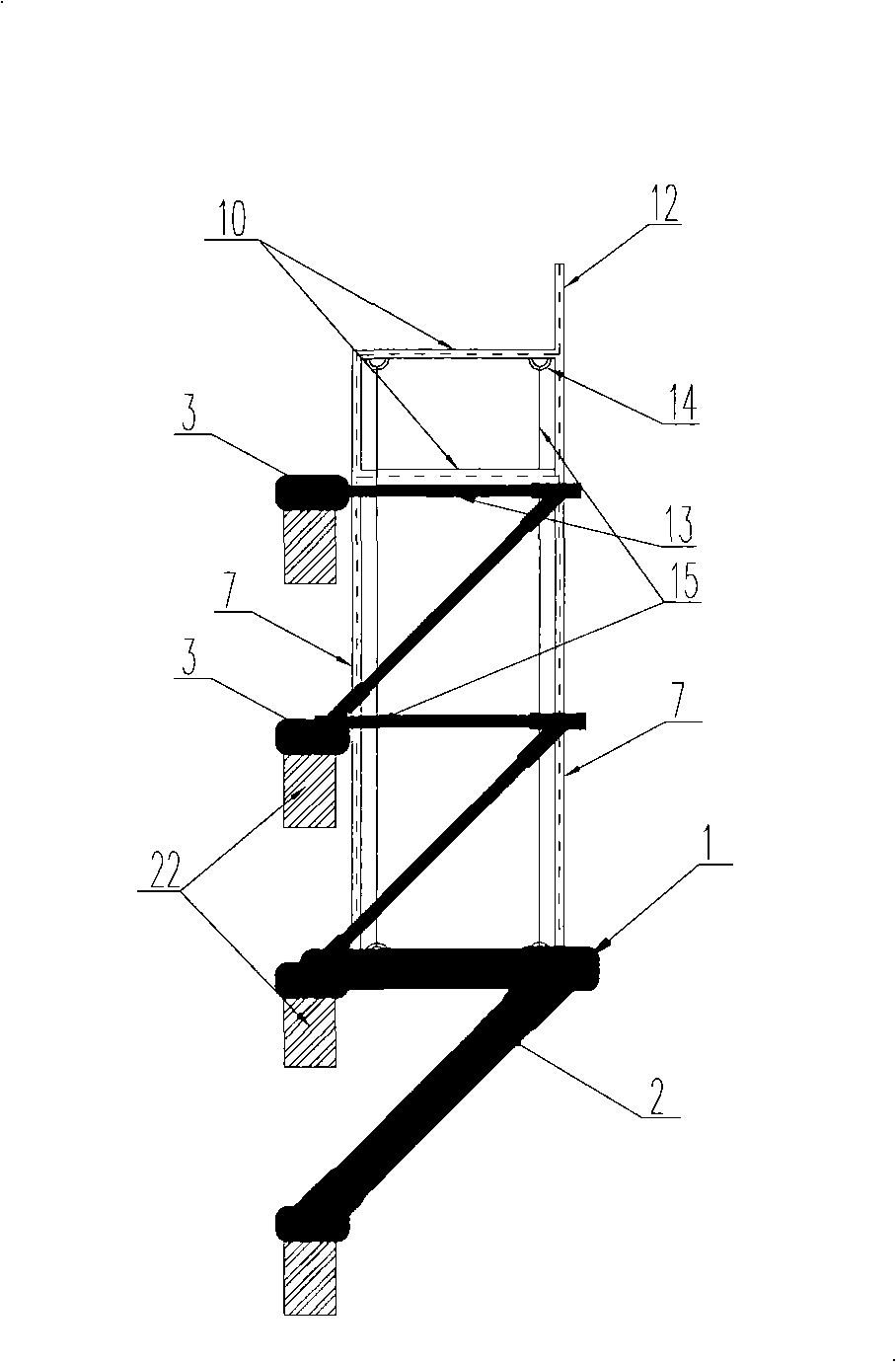

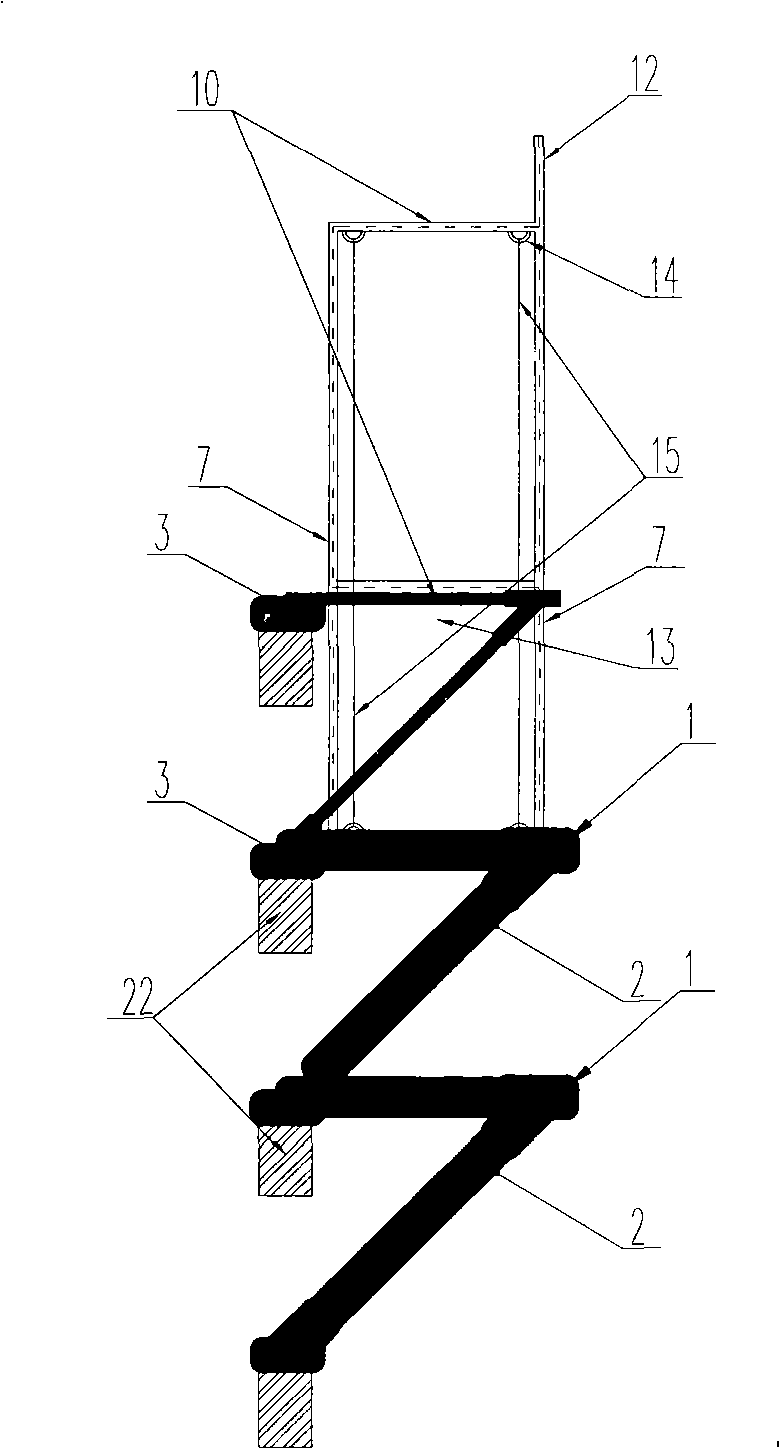

[0017] In this embodiment, the fixing device is composed of a cantilever rod 1, a strut 2, a corner ring 3, and a sleeve 6. The corner ring 3 is fixed on the beam 22, the cantilever rod 1 is fixed on the corner ring 3, the strut is connected with the cantilever rod 1 through the sleeve 6, and the other end is fixed to the corner ring 3 on the beam 22 of the next floor .

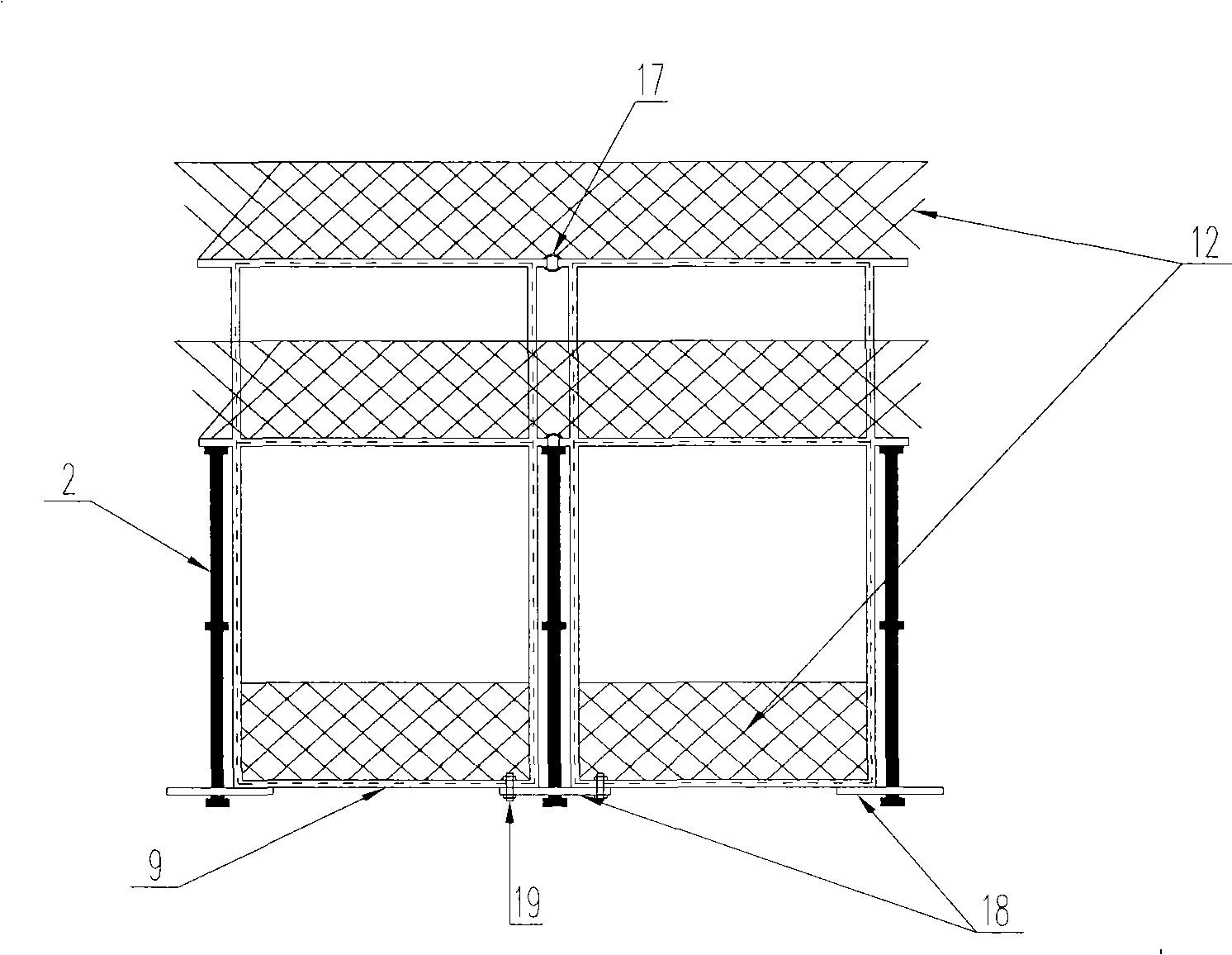

[0018] Workbench is made of foot bar 7, frame cross bar 9, frame side bar 10, scaffold board 11, tractor 13, suspension ring 14, traction rope 15, safety guardrail 12 constitutes, in the present embodiment, two of frame cross bar 9 There is a tenon at the end, and there is a tenon at the two ends of the frame side bar 10, and there is a tenon at the two ends of the foot bar 7, and they are connected by tenon and tenon. The middle layer has tractor 13, traction rope 15, suspension ring 14 control. Constitute a cuboid frame with three horizontal planes, the scaffold board 11 is placed on the three horizontal ...

Embodiment 2

[0022] In this embodiment, the workbench has seven working surfaces. During the construction process, the workbench is placed directly on the ground to complete the construction of five floors, as shown in Figure 9. When the workbench needs to be lifted, the middle layer is raised above the beams of the second floor through the tractor 13, and then the ground corner ring 3 is installed on the beams 22 of the first and second floors, and through the sleeve 6 Fix the cantilever rod 1 on the first and second floor beams 22, so that the middle layer can be placed on the cantilever rod 1 of the second floor beam 22. At this time, the tractor 13 is started to move the middle layer downward. When the floor cannot be used downward after being resisted by the cantilever rod 1 on the beam, the upper and lower floors of the workbench will be lifted up at the same time. When the bottom of the lower floor is higher than the beam 22 of the first floor, the connecting rod 18 connecting bolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com