Plug-in type copper aluminum pipe welded joint and method of producing the same

A technology for welding joints and copper-aluminum pipes, applied in welding equipment, pipes/pipe joints/pipes, resistance welding equipment, etc. Quality and strength, not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

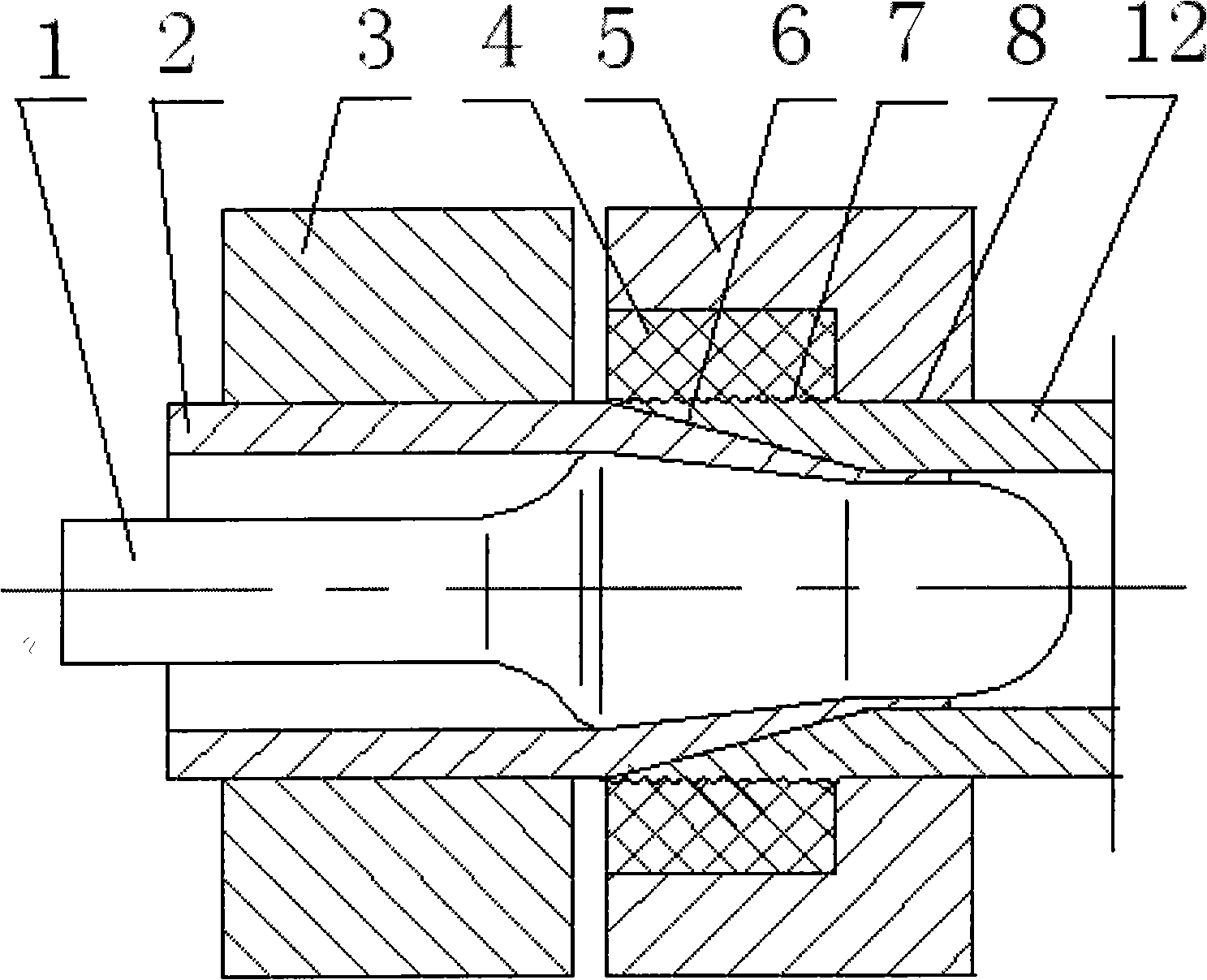

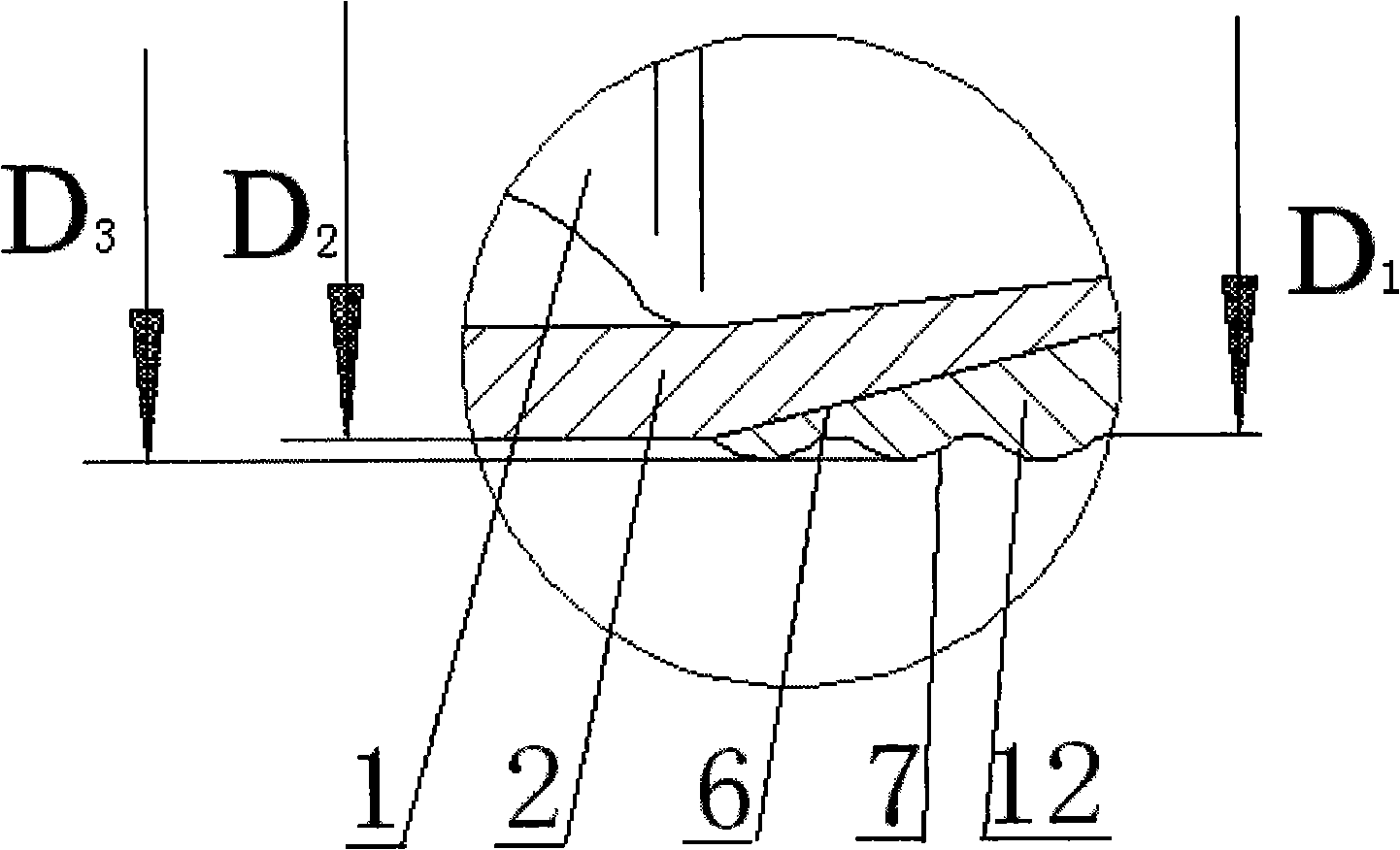

[0021] refer to figure 1 , the embodiment of the present invention is as follows: select the same copper tube 2 and aluminum tube 12 of pipe outer diameter to carry out initial processing, be about to process the welded part of copper tube pipe end into welding tapered surface 6. Put a welding mandrel 1 in advance in the inside of the copper tube 2, and make the appearance of the welding mandrel 1 coincide with the tapered welding surface of the copper tube 2, and the copper tube 2 is placed in the internal pressure resistance pressure welding machine. The middle of the moving electrode 3; the port of the aluminum tube 12 does not need to be processed, and the wall thickness and diameter are kept as they are. Wavy texture7. Such as image 3 As shown, the nominal diameter D2 of the groove is the same as the outer diameter of the aluminum tube, the minimum diameter D1 of the groove is slightly smaller than the outer diameter of the aluminum tube, and the maximum diameter D3 is...

specific Embodiment 2

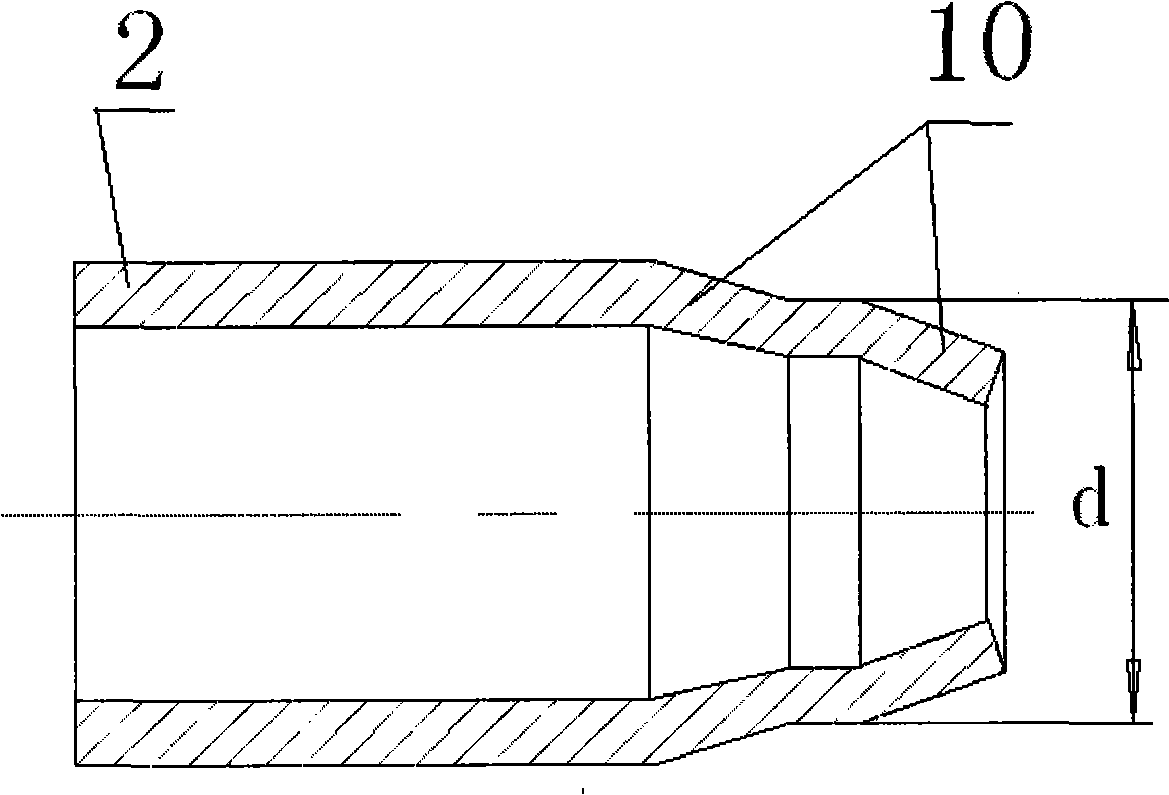

[0023] refer to image 3 , the welding tapered surface 6 of the above-mentioned copper tube 2 can also be a broken line welding surface 10, the diameter d at the broken line should be slightly larger than the inner diameter of the aluminum tube 12, which can reduce the resistance when inserting the copper tube when welding thin-walled copper and aluminum tubes , It is beneficial to prevent the deformation and instability of the copper tube, and forms a two-section fusion weld, and improves the welding fusion area and quality.

[0024] The welded joint of the plug-in copper-aluminum pipe prepared by the above method is characterized in that the aluminum pipe of the welded joint has a wave-shaped concave-convex pattern on the surface, referred to as the wave pattern.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com