Probe spring of pipe corrosion detector

A technology for detectors and pipes, which is applied in weather resistance/light resistance/corrosion resistance, instruments, measuring devices, etc. It can solve the problems of incomplete detection data, affecting detection results, impacting pipe walls, etc., and achieves easy processing, not easy to damage, The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

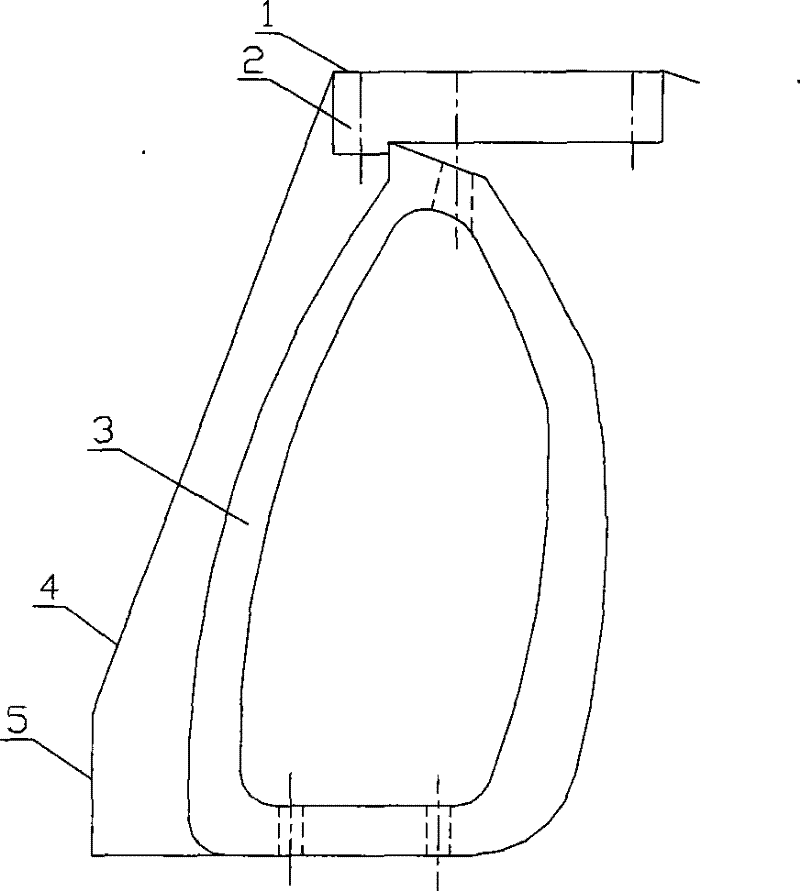

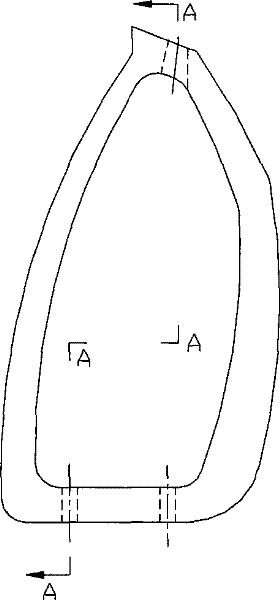

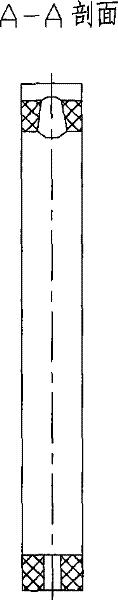

[0012] Embodiment. This example is a probe spring of a Φ1016mm high-definition pipeline magnetic flux leakage corrosion detector, and this example illustrates the specific implementation of the present invention. The shape of this ring is as figure 2 , image 3 As shown, it is similar to a triangular wine bottle shape, the main dimensions are: width 56.9mm, height 100mm, thickness 12mm; the front outer bevel is R146mm, the front inner bevel is R139mm, the outer edge of the middle and lower part of the rear bevel is R136mm, The inner edge is R128mm, bent from the 68mm distance from the bottom edge to the outer edge R146mm, the inner edge R134mm; the front and rear beveled edges meet at the top, the inner edge is R98mm, and the outer edge is R104.7mm; The diameter of the outer end of the hole is 4.5mm, and the diameter of the inner end is 6.2mm; the two holes at the bottom of the elastic ring are equal diameter holes with a diameter of 3.4mm. Install this elastic ring on the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com