Energy-saving environment-friendly type contactor

An energy-saving and environment-friendly contactor technology, applied in relays, non-polar relays, electromagnetic relays, etc., can solve the problems of high power consumption, high noise, unstable operation, etc., and achieve prolonging service life, high magnetic density, and solving heat problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] This embodiment is a preferred embodiment of the present invention, and other principles and basic structures that are the same as or similar to those of this embodiment fall within the protection scope of the present invention.

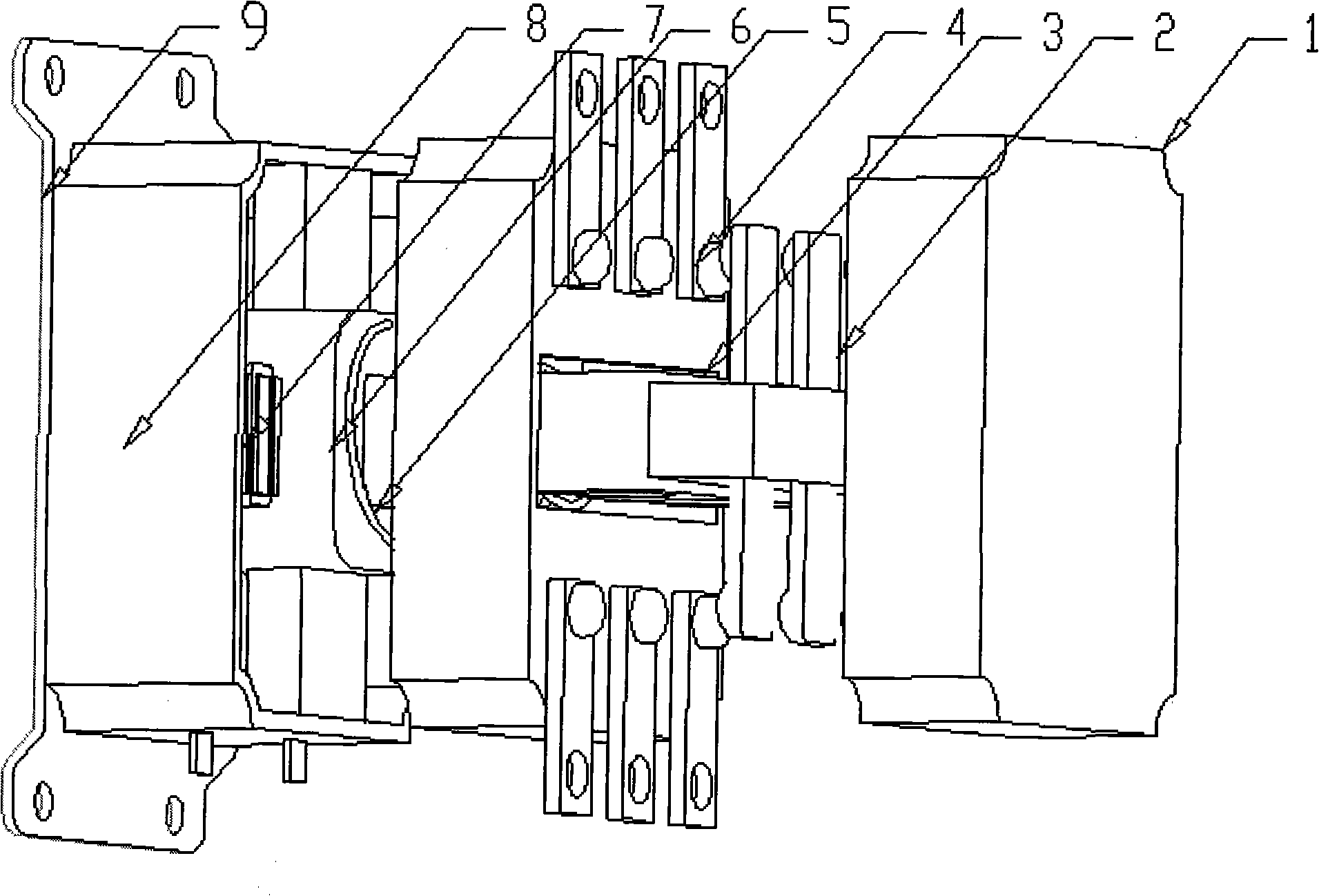

[0014] The structure of the present invention is the same as that of the contactor in the prior art. Both include a housing and an internal structure arranged in the housing. The housing includes an upper cover 1 and a bottom box 8, which are fixedly installed together to form A housing with a cavity, a bottom box 8 is fixedly installed with a mounting bottom plate 9 at the lower end, and the mounting bottom plate 9 is used to fix the present invention on the use device. The internal structure of the present invention is two "mountain"-shaped iron cores, respectively a moving iron core 3 and a static iron core 7. The static iron core 7 is fixedly installed inside the shell and is stationary, and the static iron core 7 is wound with a coil 6 , The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com