Side-installed shifting type high-tension switch cabinet

A high-voltage switchgear, removable technology, applied in the direction of pull-out switchgear, switchgear, switchgear components, etc., can solve the problems of poor safety performance, difficult to replace static contacts, poor connection strength and stability, etc. Achieve the effects of small width and depth, save floor space, and short current-carrying lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific drawings and embodiments.

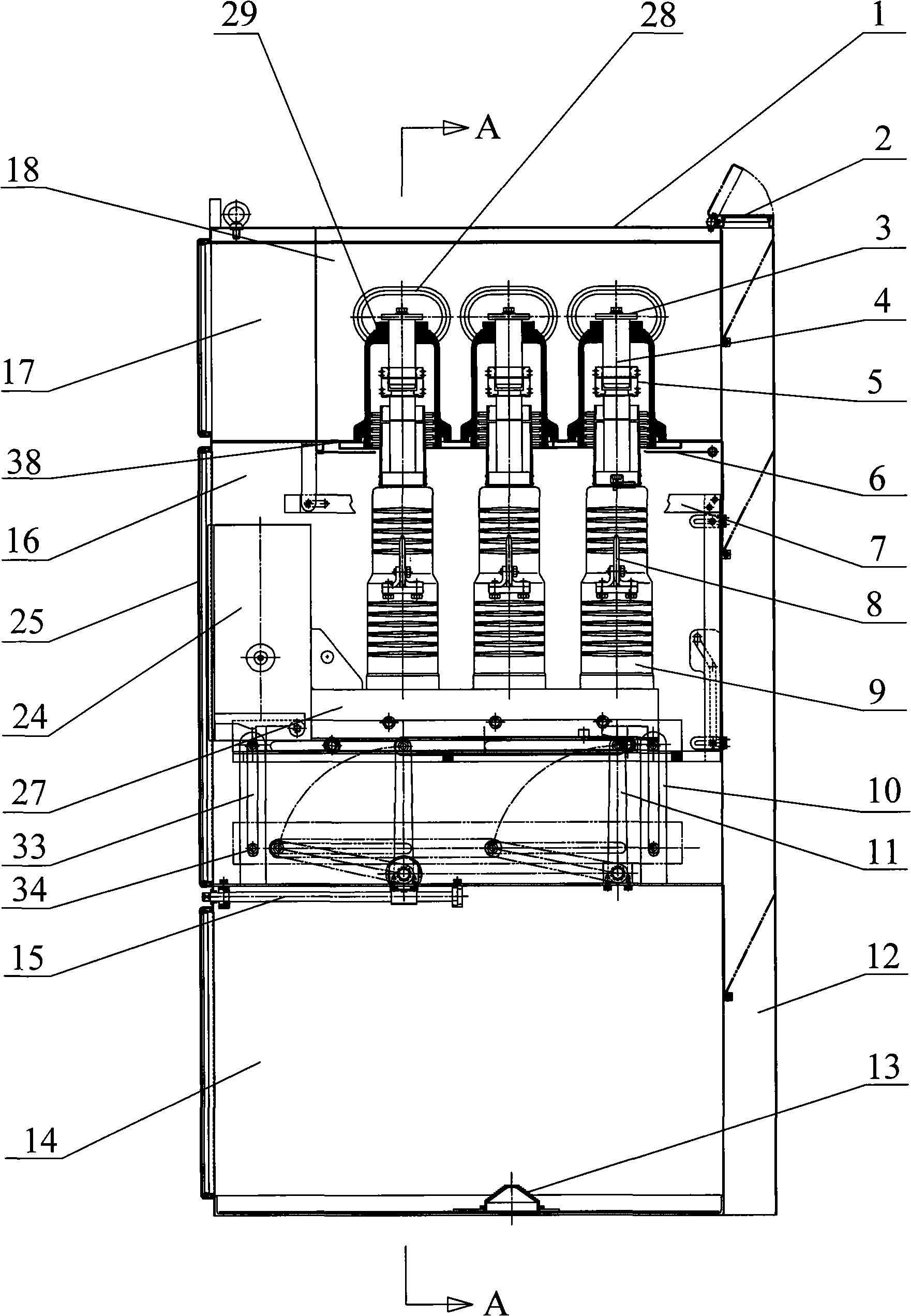

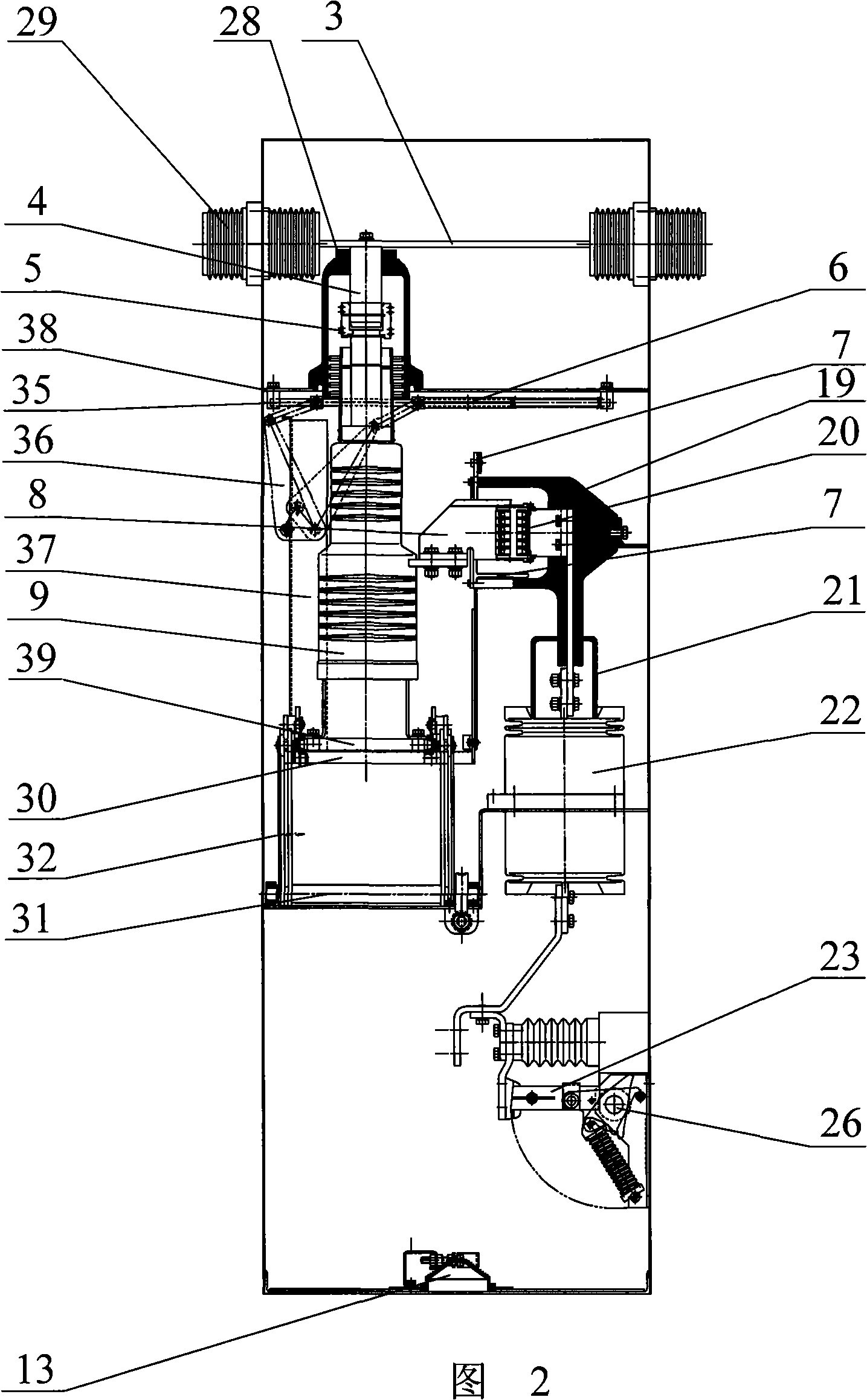

[0018] As shown in the figure: a pressure relief chamber 12 is provided on the rear wall of the housing 1, a pressure relief chamber cover 2 is provided on the top of the pressure relief chamber 12, a relay instrument room 17 is provided on the upper part of the front wall of the housing 1, and the housing 1. The inner space of 1 is busbar chamber 18, circuit breaker chamber 16 and cable chamber 14 from top to bottom. In circuit breaker chamber 16, circuit breaker operating mechanism 24, circuit breaker chassis 27, circuit breaker three-phase pole 9 and For the circuit breaker handcart composed of the handcart chassis 39, the bottom surface of the cable chamber 14 is provided with a cable plug 13, and the middle part of each phase circuit breaker pole 9 is provided with a lower moving contact 8, and the circuit breaker chamber 16 is fixed with a The lower stati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com