Low-voltage high power multi-branch permanent magnet synchronous motor

A permanent magnet synchronous, high-power technology, applied in the direction of electric components, magnetic circuit rotating parts, electrical components, etc., can solve the problem of not solving the problem of high current, and achieve the effect of superior performance, cost reduction and energy saving effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

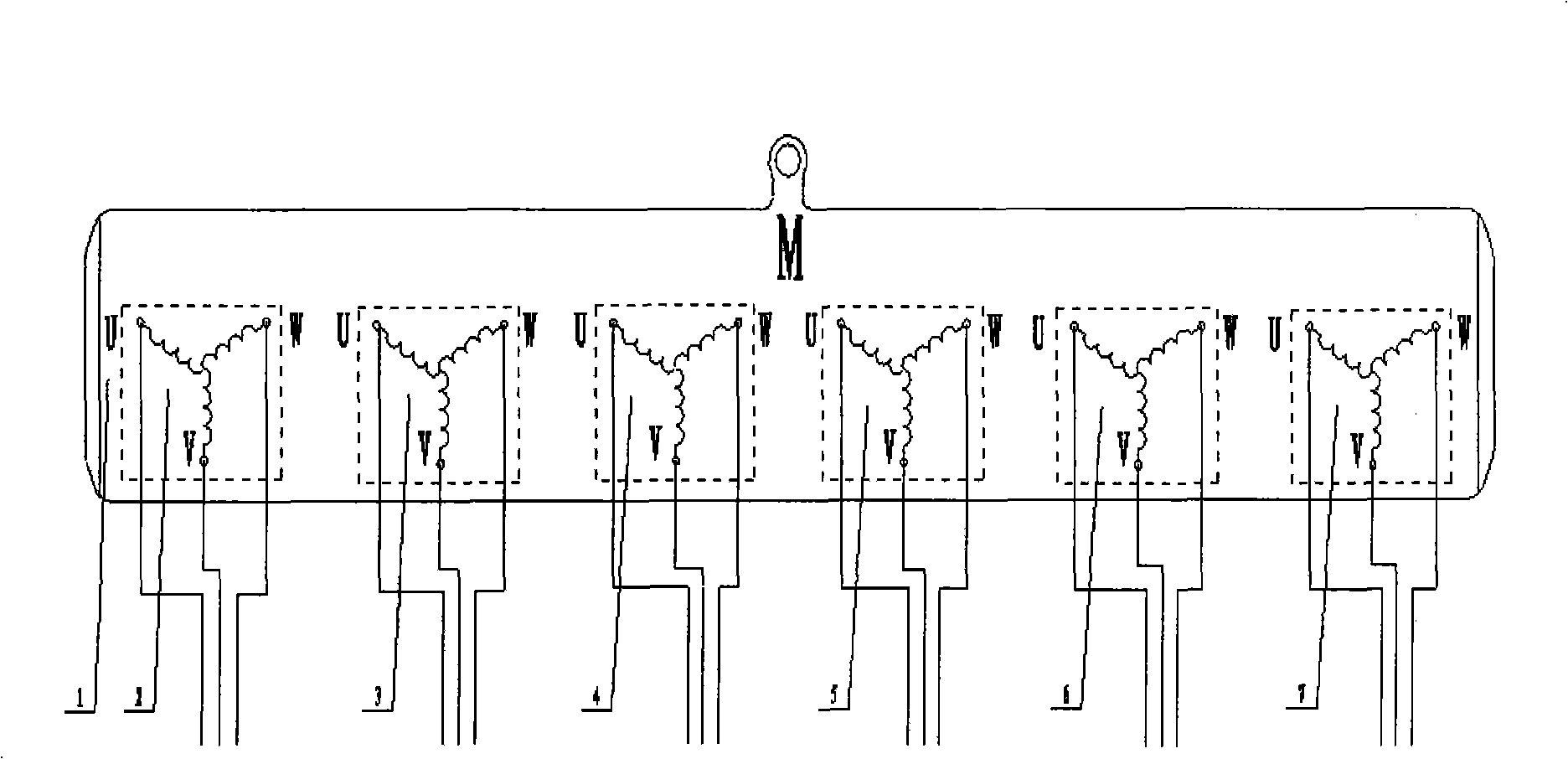

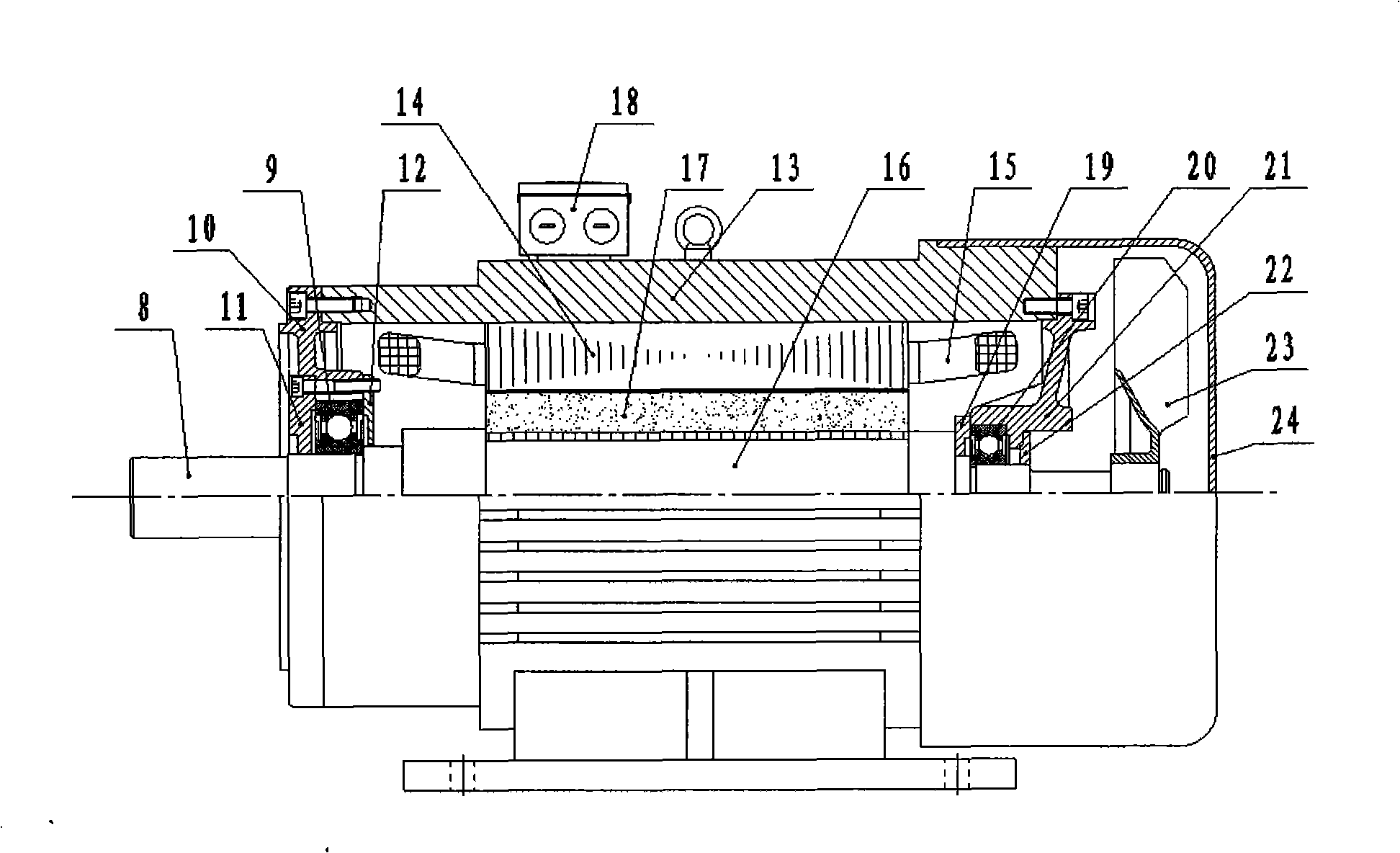

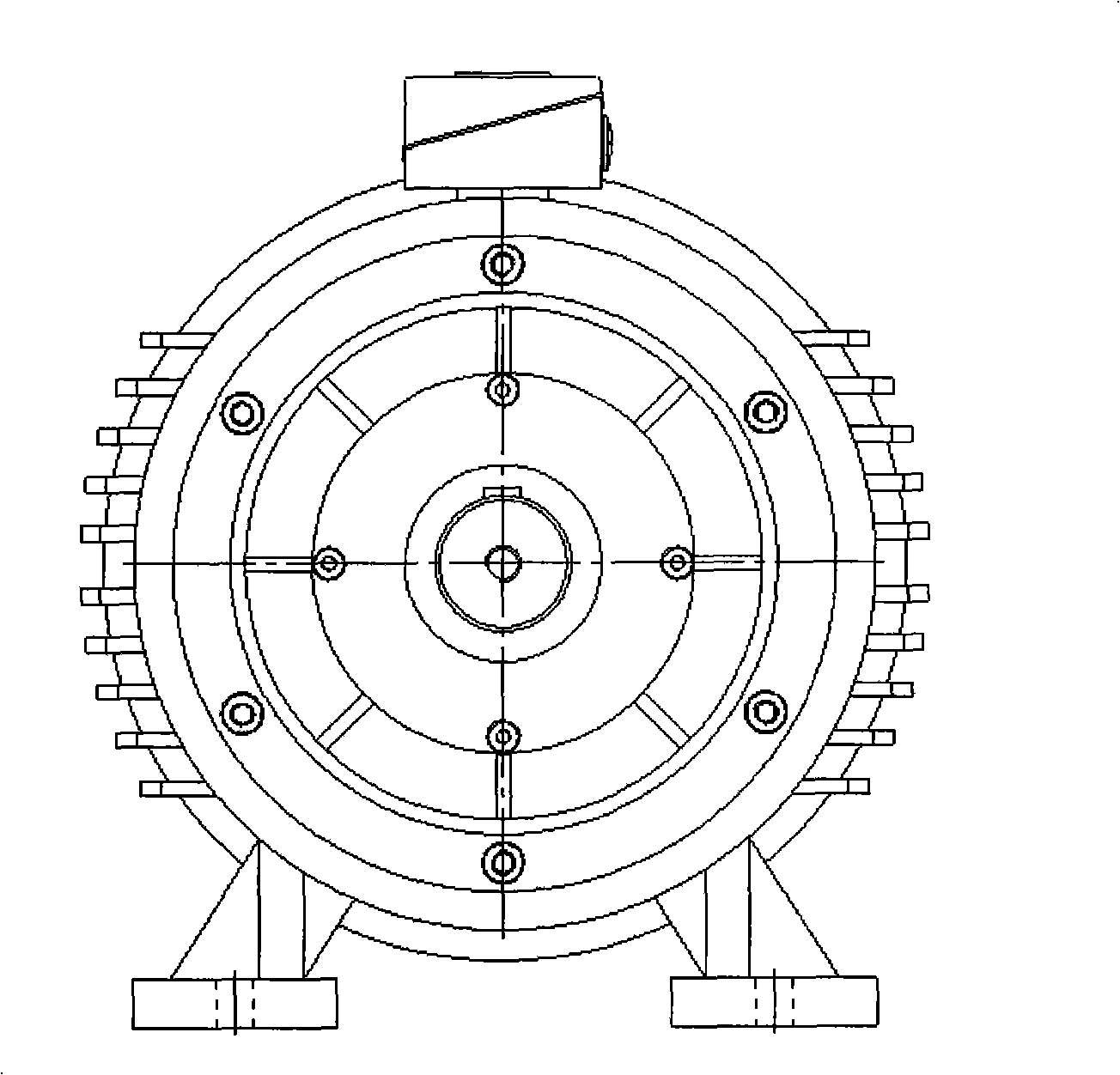

Embodiment 1

[0020] Embodiment 1 includes: permanent magnet synchronous motor housing 1, rotating shaft 8, left bearing 9, front end cover 10, left bearing outer cover 11, left bearing inner cover 12, machine base 13, stator core 14, stator winding 15, rotor 16 , permanent magnet 17, junction box 18, right bearing inner cover 19, right bearing 20, rear end cover 21, right bearing outer cover 22, fan 23, fan cover 24, junction box 18, bolt 18-1, terminal block 18- 2. Junction bucket 18-3, junction box seat 18-4. The left bearing outer cover 11 and the left bearing inner cover 12 are mounted on the front end cover 10 by bolts, the front end cover 10, the rear end cover 21 and the junction box 18 are respectively mounted on the machine base 13 with bolts, and the left bearing 9 is mounted on the rotor 16 Sandwiched between the left bearing outer cover 11 and the left bearing inner cover 12, the stator core 14 is directly mounted on the machine base 13 with bolts, the stator windings 15 are di...

Embodiment 2

[0021] The basic structure of the second embodiment is the same as that of the first embodiment, wherein the number of sub-winding groups is the same as the number of poles of the permanent magnet synchronous motor, and the rotor magnetic circuit structure is surface type.

Embodiment 3

[0022] The basic structure of the third embodiment is the same as that of the first embodiment, wherein the number of sub-winding groups is three times the number of poles of the permanent magnet synchronous motor, and the rotor magnetic circuit structure is a built-in type.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com