Optical information recording medium, method for visible information recording, method for use of mixture and mixture

A technology for optical information and recording media, which is applied in the direction of optical recording media, optical recording/reproduction, data recording, etc., can solve the problems of insufficient light durability and/or thermal durability, and achieve excellent light durability and The effect of thermal durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

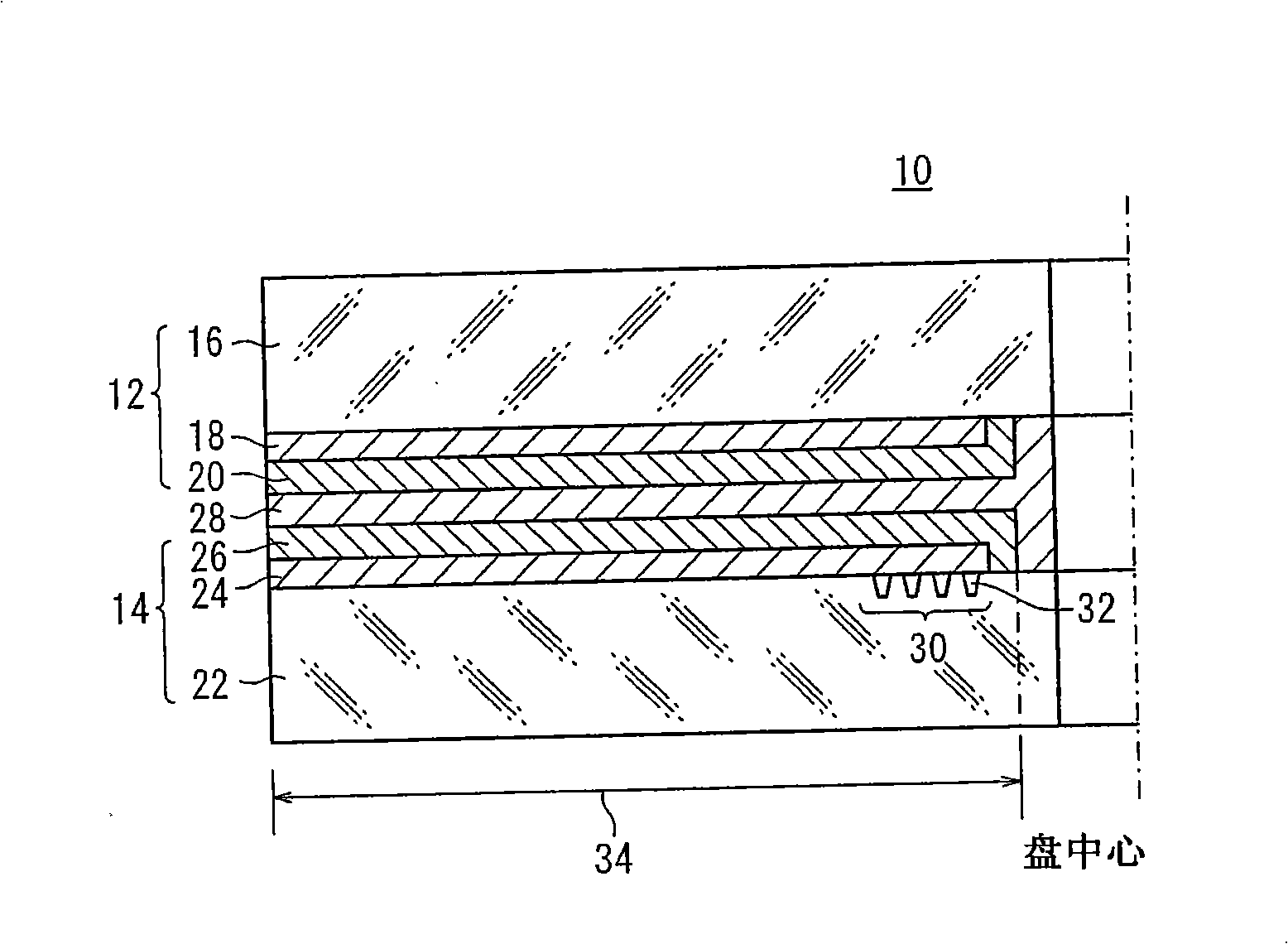

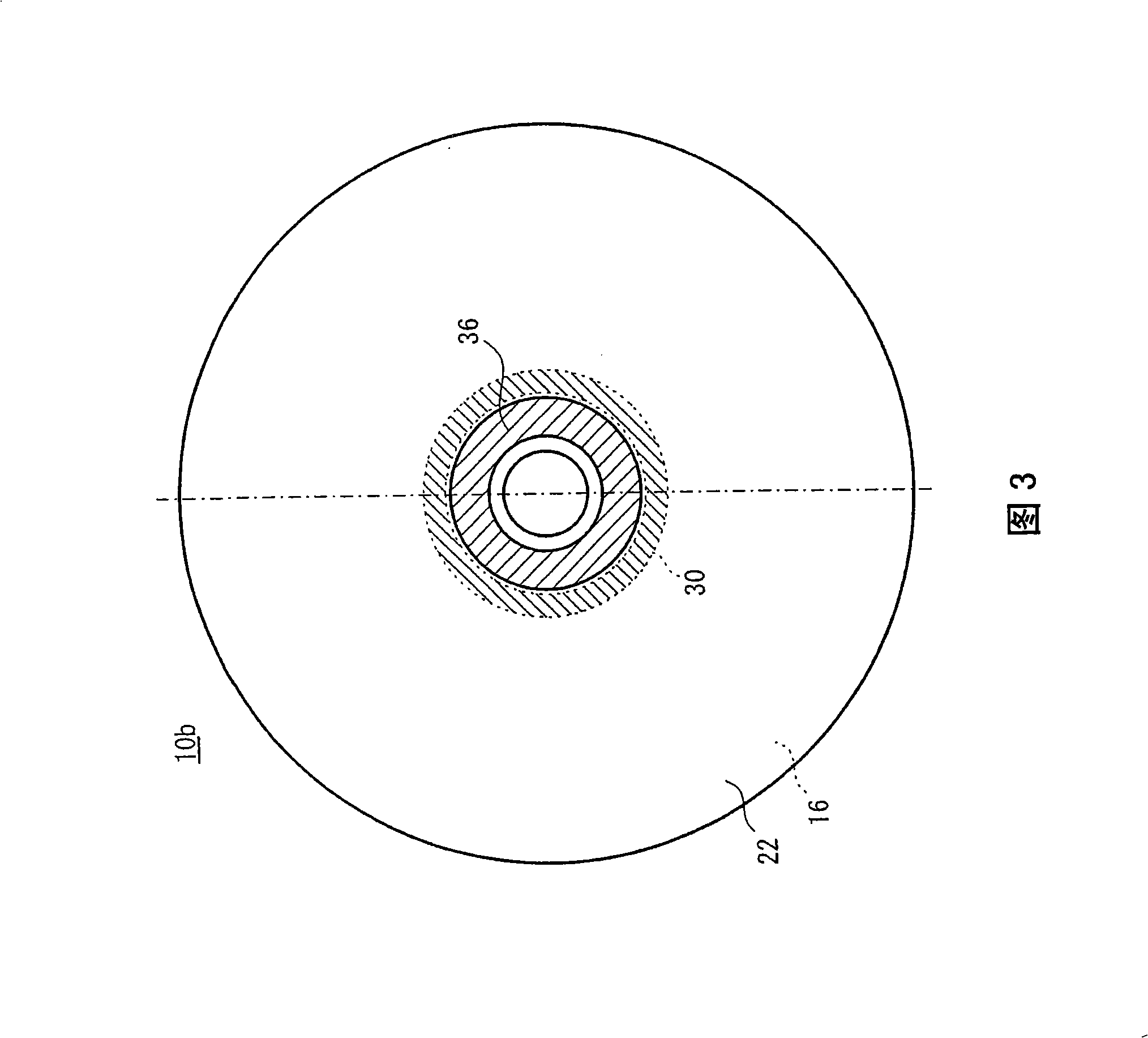

[0364] The optical information recording medium of Example 1 is a DVD-R type optical information recording medium obtained by bonding two discs together. A method for manufacturing the optical information recording medium of Example 1 will be explained below.

[0365] Using polycarbonate resin, a first substrate 16 having a thickness of 0.6 mm and a diameter of 120 mm in which helical (helical) grooves (depth: 130 nm, width: 300 nm, track pitch: 0.74 μm) was formed was formed by injection molding.

[0366] Then, 1.5 g of an oxonol dye represented by the following general formula (ch-63) and 1.5 g of an oxonol dye represented by the following general formula (ch-64) were dissolved in 100 ml of 2,2,3, 3,-Tetrafluoro-1-propanol to prepare the coating solution. The coating liquid was applied onto the surface of the first substrate 16 on which the pre-groove 40 was formed by a spin coating method, whereby the data recording layer 18 was formed.

[0367]

[0368]

[0369] Su...

Embodiment 2 to 4

[0375]Among the optical information recording media according to Examples 2 to 4, a first optical information recording medium 10A was prepared in substantially the same manner as in Example 1 except that, as shown in FIG. The content of metal atoms contained in the coating solution for forming the visible information recording layer used for the visible information recording layer 24 of the visible information recording medium portion 14 of Example 1.

[0376] (contrast evaluation)

[0377] On the optical information recording media manufactured according to the first to fourth embodiments, recording was performed as follows.

[0378] Using the recording apparatus disclosed in Japanese Laid-Open Patent Publication 2002-203321, that is, a recording apparatus having a laser pickup emitting a laser beam 38 and a rotation mechanism for rotating an optical information recording medium (using a semiconductor laser having a wavelength of 660 nm as the laser beam source), based on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com