Desulfuration method in circulating fluid bed boiler using shell

A circulating fluidized bed and boiler technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., to achieve the effect of simple desulfurization system, easy desulfurization, and easy acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

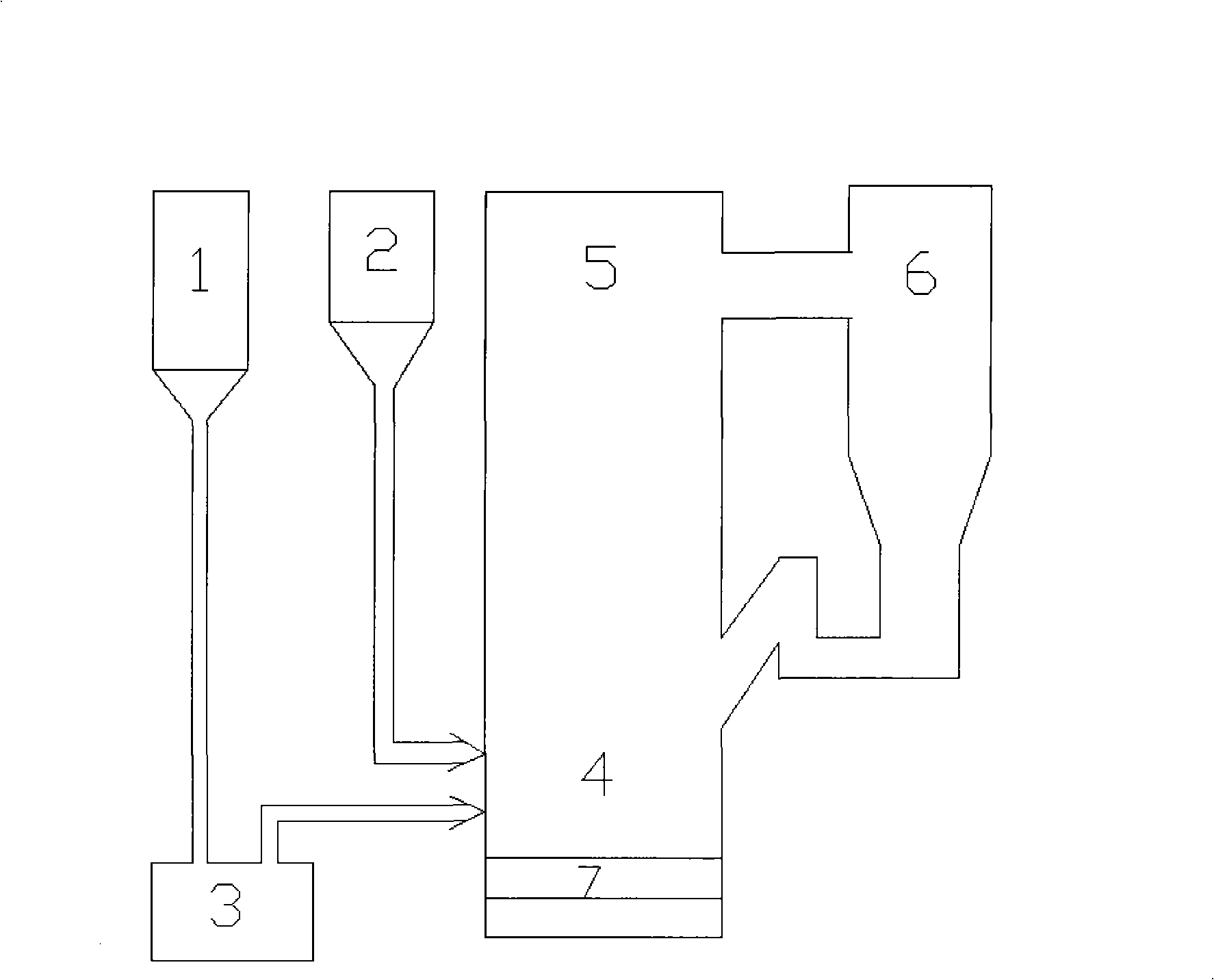

[0020] Such as figure 1 As shown, it is a schematic diagram of a desulfurization method utilizing shells in a circulating fluidized bed boiler, and a desulfurization method utilizing shells in a circulating fluidized bed boiler is:

[0021] The first step, first choose CaCO 3 Shells with a mass content higher than 70% are then dried and pulverized to make granules with a particle size of 0.1 mm to 4 mm and placed in the shell granule bin 2;

[0022] In the second step, quartz sand is used as the medium material 7 of the circulating fluidized bed boiler, and the screening particle size of the medium material 7 is 0.3 mm to 4 mm. The material adding device is used to add the medium material 7 to the bottom of the circulating fluidized bed boiler 4, and it is static The thickness of the media material 7 is between 650mm;

[0023] In the third step, when running the circulating fluidized bed boiler, heat the media material 7 to 800°C with an external heat source, and at the same...

Embodiment 2

[0026] A desulfurization method using shells in a circulating fluidized bed boiler is:

[0027] The first step, first choose CaCO 3 Shells with a mass content higher than 70% are then dried and pulverized to make granules with a particle size of 0.1 mm to 4 mm and placed in the shell granule bin 2;

[0028] In the second step, quartz sand is used as the medium material 7 of the circulating fluidized bed boiler, and the screening particle size of the medium material 7 is 0.3 mm to 4 mm. The material adding device is used to add the medium material 7 to the bottom of the circulating fluidized bed boiler 4, and it is static The thickness of the media material 7 is between 600mm;

[0029] In the third step, when running the circulating fluidized bed boiler, first heat the media material 7 to 850°C with an external heat source, and at the same time adjust the air supply volume so that the media material 7 is in a fluidized state, and the fuel in the fuel tank 1 is sent through the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com