Non-clutch shift control method and control system of pure electric vehicle

A shift control, pure electric technology, applied in the direction of electric vehicles, vehicle components, electric traction, etc., can solve the problems such as deceleration and shifting, the impact of vehicle maneuverability, etc., and achieve the effect of improving maneuverability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

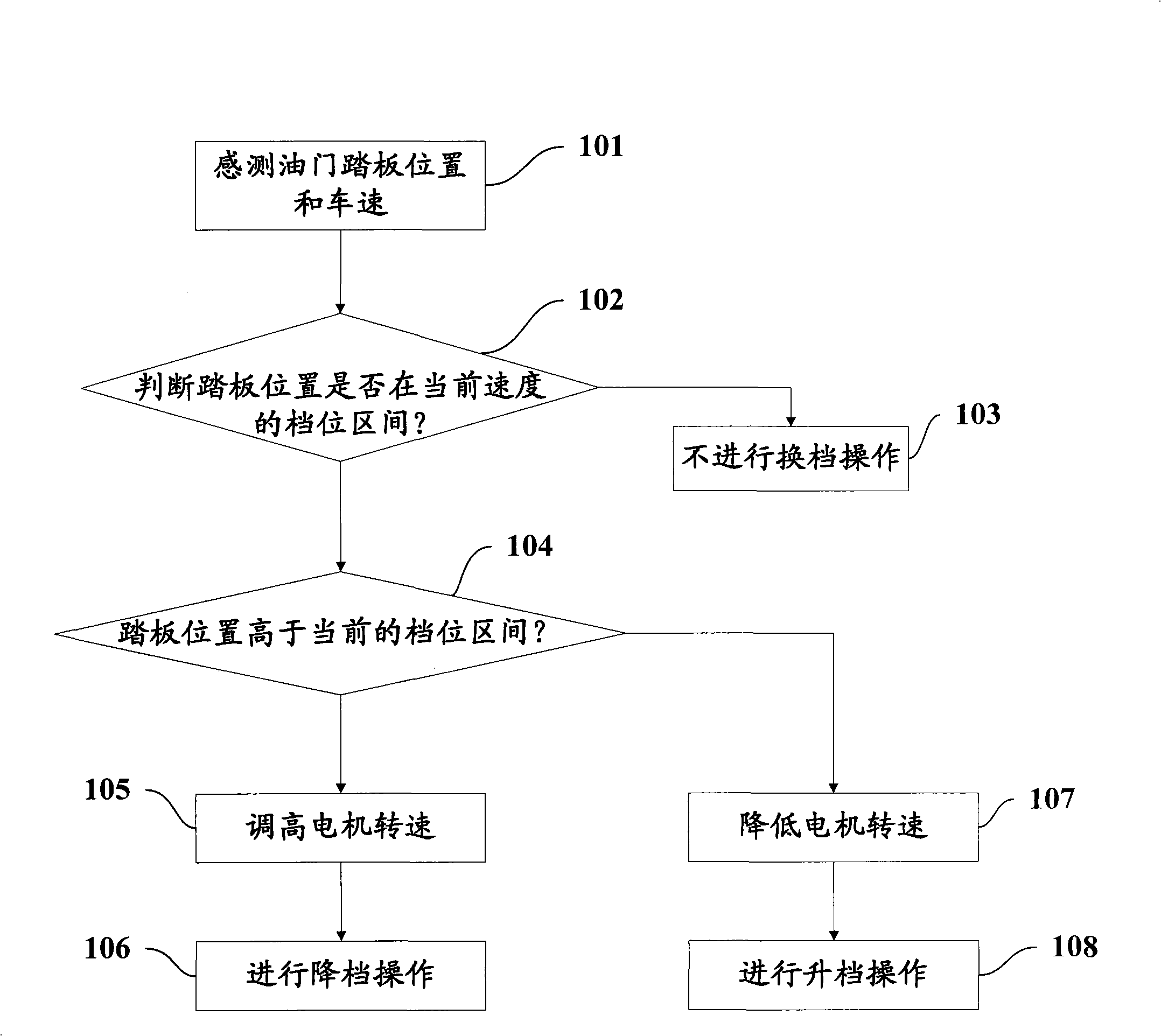

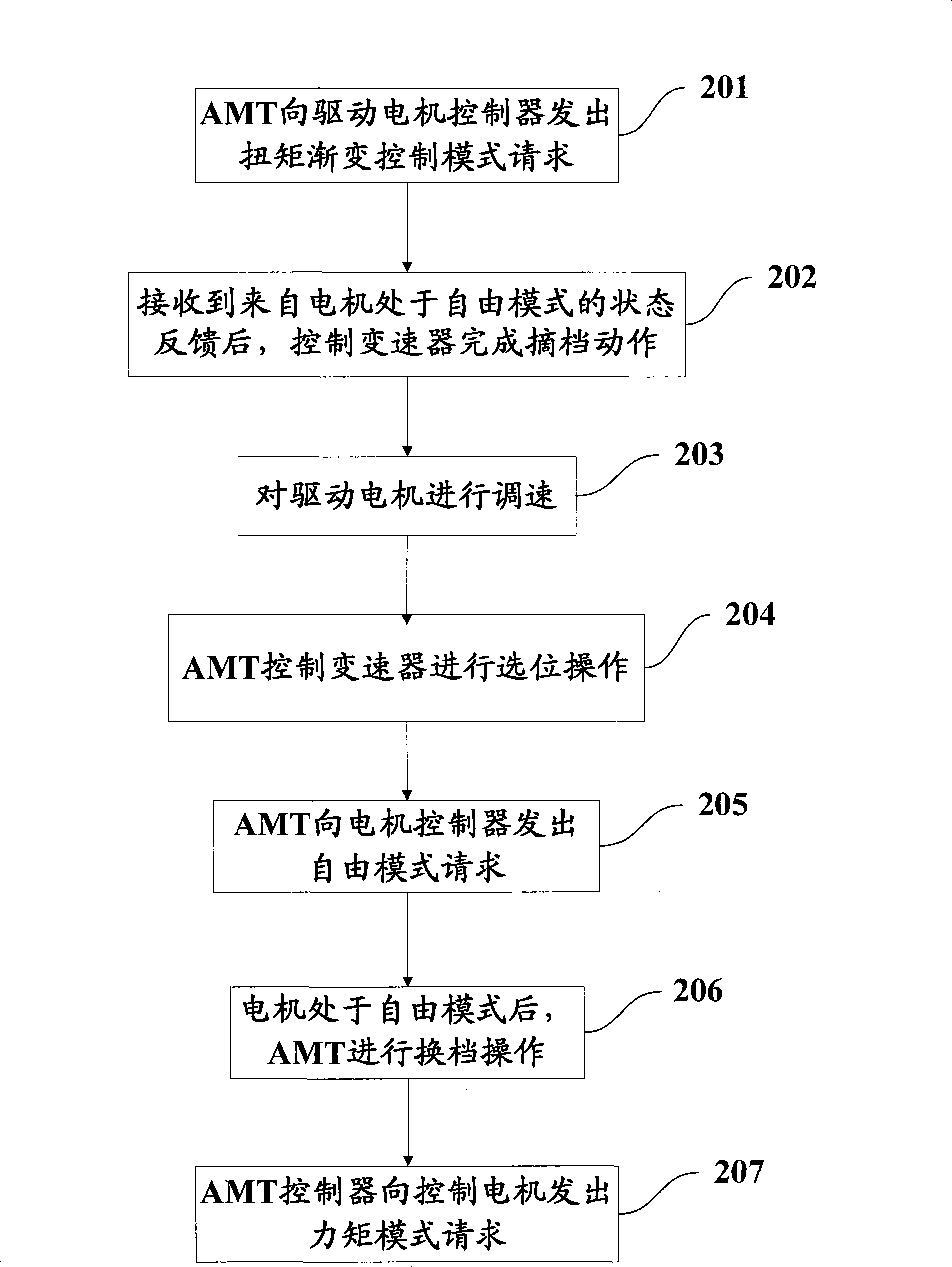

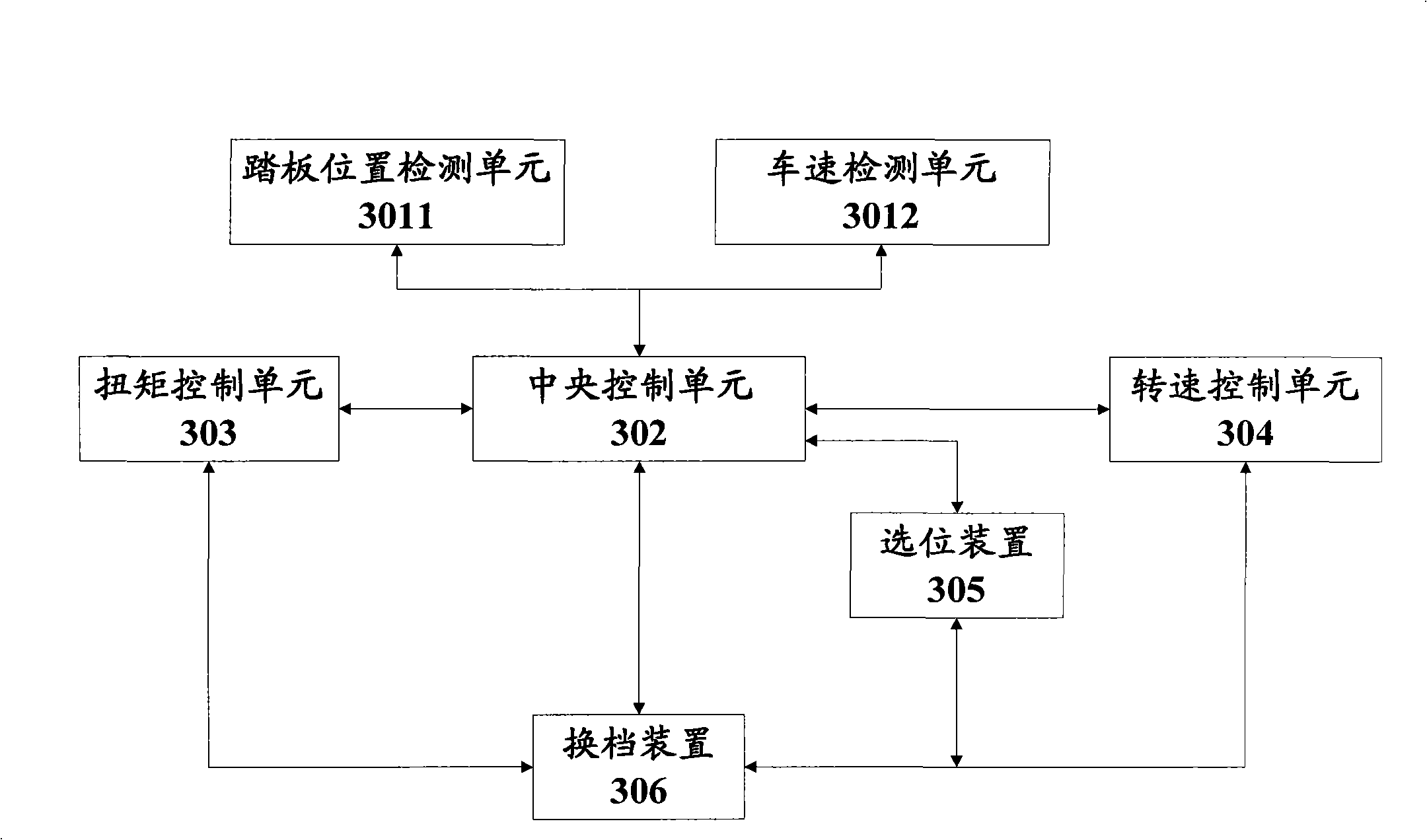

[0016] During the driving process of the pure electric vehicle, the power output of the drive motor is directly connected to the drive axle through the multi-speed reducer without passing through the clutch, so as to realize clutchless gear shifting. The driver controls the driving speed of the vehicle completely through the accelerator, while the shifting process in the gearbox is completely automatically completed under the relevant control devices of the vehicle.

[0017] During the working process of the electric vehicle, the electric energy of the battery is converted into AC current, and the motor controller will generate corresponding current according to the power required by the vehicle. The torque of the motor is decelerated and increased through the gearbox. According to the needs of the road, the automatic transmission system (AMT) controller generates corresponding control commands to select different gears. The gearbox torque is transmitted to the rear axle final ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com