Method for preparing building block composite split joint type energy-saving wall board

A splicing and wall panel technology, which is applied in the direction of building components, buildings, building structures, etc., can solve problems such as walls and roofs that are prone to cracks, and achieve good sound and heat insulation effects, light weight, and tight joints.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

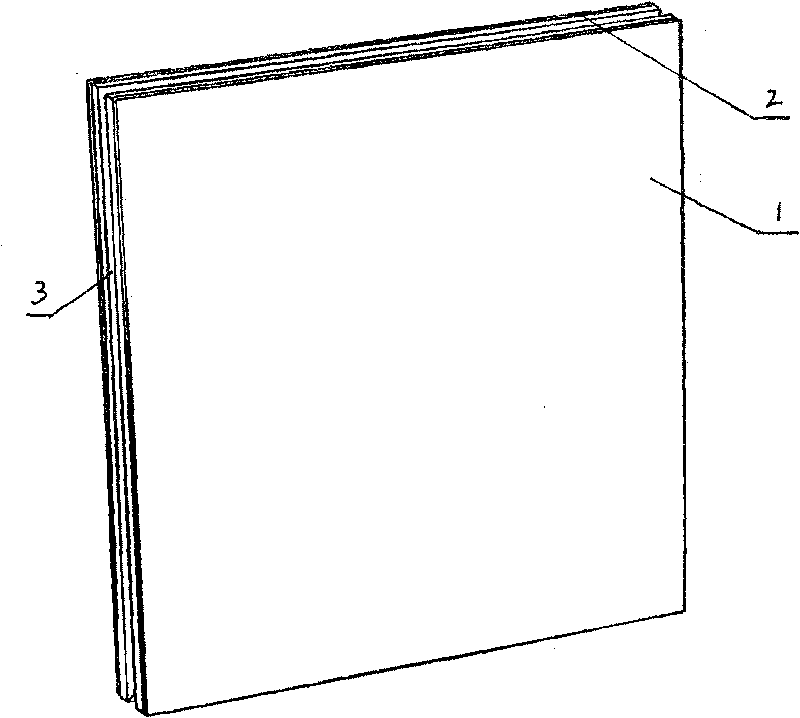

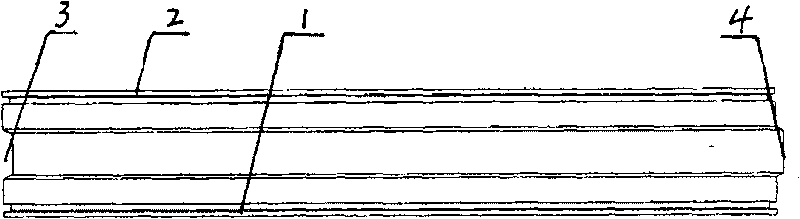

[0042] A method for preparing building block combined and spliced energy-saving wall panels, characterized by:

[0043] A. First fix the front panel 1 and the rear panel 2 on the four side molds, so that the front panel 1, the rear panel 2 and the four side molds are put together to form an integral hollow wall panel frame;

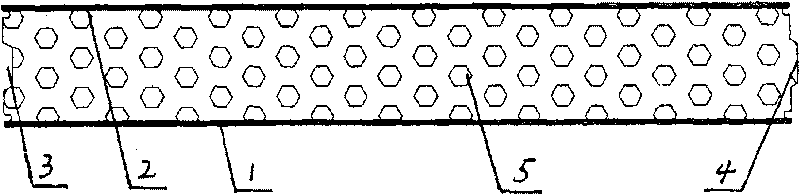

[0044] B. Add cement to the recycled polystyrene foam particles, perlite or the mixture of recycled polystyrene foam particles and perlite, and then add cement foaming agent, and mix well to make a paste that can play the role of heat preservation and sound insulation. fill layer 5;

[0045] C. Inject the pasty intermediate filling layer 5 into the hollow wallboard frame through the small hole on the side mould, using the tunnel high-pressure pouring method;

[0046] D. After pouring, solidify on the conveyor belt, remove the four side molds, and then place them flat for maintenance. After the wallboard is cooled, it will be packaged to obtain the fini...

Embodiment 2

[0051] The preparation method of embodiment 2 is substantially the same as embodiment 1, the difference is:

[0052] The left splicing groove is the first left splicing groove 3 and the left splicing convex groove 6, and the right splicing groove is the first right splicing convex groove 4 spliced with the first left splicing groove 3 and the left splicing convex groove 6. The spliced right splicing groove 7, and the shape of the first left splicing groove 3, the first right splicing convex groove 4, the left splicing convex groove 6 and the right splicing groove 7 is square.

[0053] The material of the front panel 1 and the rear panel 2 is calcium silicon board.

Embodiment 3

[0055]The preparation method of embodiment 3 is substantially the same as embodiment 1, the difference is:

[0056] The left splicing groove is the first left splicing groove 3 and the left splicing convex groove 6, and the right splicing groove is the first right splicing convex groove 4 spliced with the first left splicing groove 3 and the left splicing convex groove 6. The spliced right splicing groove 7, and the shape of the first left splicing groove 3, the first right splicing convex groove 4, the left splicing convex groove 6 and the right splicing groove 7 is a semicircle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com