Heat preservation wall slab for rear wall of greenhouse

A technology for thermal insulation wall panels and greenhouses, which is applied to building components, buildings, building structures, etc., can solve the problems of fast heat dissipation, waste of fuel resources, and no thermal insulation function in greenhouses, and achieves the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

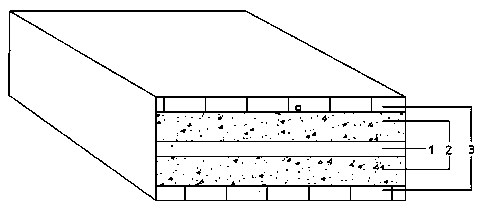

Image

Examples

Embodiment 2

[0024] Embodiment 2 of the thermal insulation wallboard for the back wall of the greenhouse is:

[0025] The central ply is made of aluminum alloy, wood-plastic, aluminum-plastic, and polystyrene foam particles by one-time pressing, wherein the mass ratio of each component is aluminum alloy: wood-plastic: aluminum-plastic: polystyrene foam particles=0.31: 1:0.6:2.3.

[0026] The thermal insulation layer is composed of two foam plastic boards bonded by adhesive material layers.

[0027] The composition weight ratio of the flame retardant layer is: 53kg of magnesium chloride, 4.5kg of magnesium oxide, 42kg of expanded vermiculite, 160kg of binder, and 1.2kg of emulsifier.

[0028] The preparation raw materials of the adhesive material layer are composed of caustic dolomite (CaO·MgO), Na 3 PO 4 , MgCl 2 , SiO 2 Composition, the ratio of each raw material is: caustic dolomite (CaO MgO): Na 3 PO4: MgCl 2 : SiO 2 =2.2:0.06:0.12:2.2.

[0029] Described binding agent is Ameri...

Embodiment 3

[0030] Embodiment 3 of the thermal insulation wallboard for the back wall of the greenhouse is:

[0031] The central ply is made of aluminum alloy, wood-plastic, aluminum-plastic, and polystyrene foam particles by one-time pressing, wherein the mass ratio of each component is aluminum alloy: wood-plastic: aluminum-plastic: polystyrene foam particles=0.36: 1.4:0.7:2.7.

[0032] The thermal insulation layer is composed of two foam plastic boards bonded by adhesive material layers.

[0033] The composition weight ratio of the flame retardant layer is: 55kg of magnesium chloride, 5kg of magnesium oxide, 43kg of expanded vermiculite, 165kg of binder, and 1.4kg of emulsifier.

[0034] The preparation raw materials of the adhesive material layer are composed of caustic dolomite (CaO·MgO), Na 3 PO 4 , MgCl 2 , SiO 2 Composition, the ratio of each raw material is: caustic dolomite (CaO MgO): Na 3 PO4: MgCl 2 : SiO 2 =2.3:0.05:0.13:2.3.

[0035] Described binding agent is Ameri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com