Lightweight and high-strength photovoltaic module and preparation method thereof

A photovoltaic module and high-strength technology, which is applied in the field of solar cells, can solve the problems that the snow load and wind load test of photovoltaic modules cannot meet the design specifications, reduce the strength of the modules, and are not enough, and achieve the goal of promoting the process of photovoltaic civilianization, weight reduction, high energy consumption, etc. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0086] The present invention also provides a method for preparing a light-weight and high-strength photovoltaic module, which comprises the following steps:

[0087] S1, prepare a polymer reinforcement layer pre-product;

[0088] S2, prepare the encapsulation film;

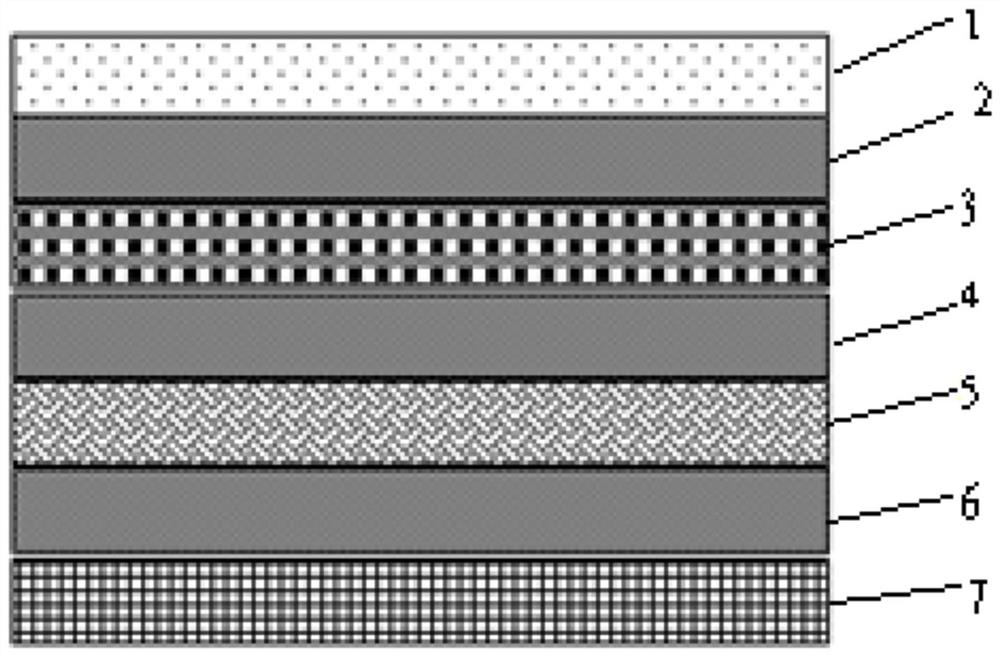

[0089] S3. Lay the front glass, the first encapsulation film, the battery string, the second encapsulation film, the polymer reinforcement layer prefabricated product and the photovoltaic backplane in sequence from top to bottom;

[0090] S4. Place the laid overall structure in a preheated laminator, and under the working conditions of a temperature of 130-180°C and a pressure of 10-1000kPa, heat for 5-30min to perform lamination;

[0091] S5, post-processing.

[0092] In one embodiment, in step S1, the preparation of the polymer reinforcement layer preform includes:

[0093] The thermosetting powder is placed under a working condition of a temperature of 80-130° C., heated for 1-10 minutes, melted, and cooled ...

Embodiment 1

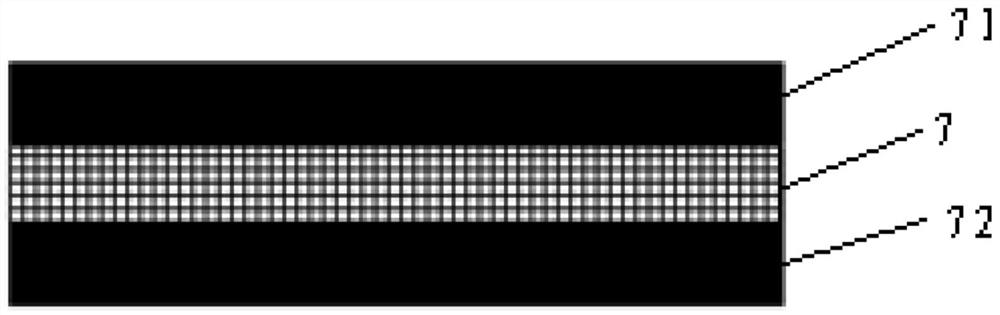

[0101] The polymer powder material with a diameter of 10-200μm thermosetting polyacrylic acid as the main resin, adding curing agent, auxiliary agent and coupling agent, after post-processing, granulation and grinding, is spread evenly on the unit gram weight of 300g / m2. 2 On the glass fiber woven cloth, heat the powder at 80-130 ℃ for 1-10 minutes to melt the powder, and after cooling, prepare a continuous integrated composite material, and cut the prepared continuous integrated composite material according to the designed size. to obtain a copolymer reinforcement layer preform;

[0102] Prepare 2.0mm thick ultra-white embossed low-iron coated tempered glass, polyolefin encapsulation film, battery string, two layers of ethylene-vinyl acetate copolymer film and transparent CPC photovoltaic backplane according to the set size;

[0103] Lay ultra-white embossed low-iron coated tempered glass, polyolefin film, battery string, ethylene-vinyl acetate copolymer film, polymer reinfor...

Embodiment 2

[0107] The polymer powder material with a diameter of 10-200μm thermosetting polyester as the main resin, adding curing agent, auxiliary agent and coupling agent, after post-processing, granulation and grinding, is spread evenly on the unit gram weight of 300g / m2. 2 On the glass fiber woven cloth, heat the powder at 80-130 ℃ for 1-10 minutes to melt the powder, and after cooling, prepare a continuous integrated composite material, and cut the prepared continuous integrated composite material according to the designed size. to obtain a copolymer reinforcement layer preform;

[0108] Prepare 2.0mm thick ultra-white embossed low-iron coated tempered glass, polyolefin encapsulation film, battery string, two layers of ethylene-vinyl acetate copolymer film and transparent CPC photovoltaic backplane according to the set size;

[0109] Lay ultra-white embossed low-iron coated tempered glass, polyolefin film, battery string, ethylene-vinyl acetate copolymer film, polymer reinforcement ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com