Method for preparing split joint buckled type building block composite energy-saving wall board

A technology of wallboards and building blocks, which is applied in the field of preparation of energy-saving wallboards combined with buckle-type building blocks, can solve the problems affecting the progress of decoration and the time of moving in, and increase the decoration procedures, etc., and achieve good sound and heat insulation effects, fast construction and installation, and high quality light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] A preparation method of spliced button building block combined energy-saving wallboard, characterized in:

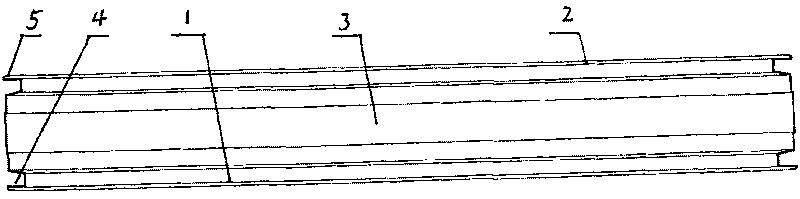

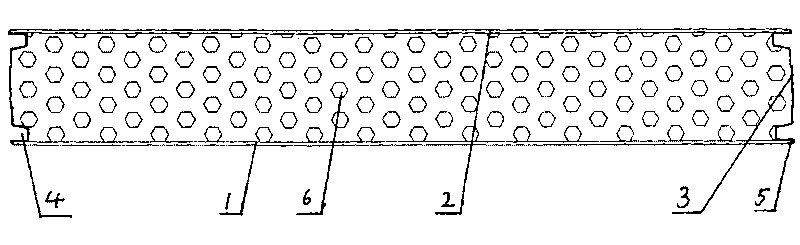

[0065] A. First, use hard plastic, aluminum alloy, stainless steel, aluminum-plastic, wood-plastic or plastic steel to form the side plate 3 at one time. Both ends of the side plate 3 are processed with panel splicing grooves 5 and splicing buttons 7 or 8 The wall panel splicing groove 4 for splicing, the wall panel splicing groove 4 and the panel splicing groove 5 have opposite directions;

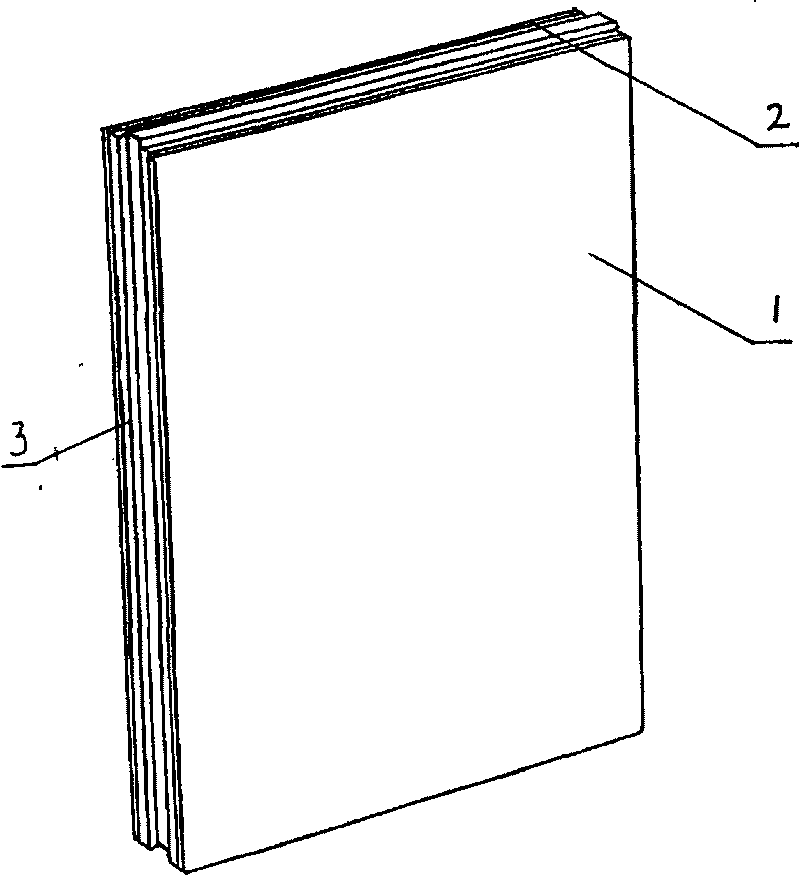

[0066] B. Insert the front panel 1 and the rear panel 2 into the panel splicing grooves 5 at the ends of the four side panels 3 respectively, so that the front panel 1, the rear panel 2 and the four side panels 3 are joined together to form an integral hollow wall panel frame ;

[0067] C. Add cement to the recycled polystyrene foam particles, perlite or the mixture of recycled polystyrene foam particles and perlite, and then add cement foaming agent, and mix well to make a paste...

Embodiment 2

[0074] The preparation method of Example 2 is basically the same as that of Example 1, except that:

[0075] At the top end of the panel splicing groove 5 of each side panel 3, a side panel inner groove 9 is processed so that the front panel 1, the rear panel 2 are flush with the side panel 3, and the front panel 1 and the rear panel 2 face outward. The edges of the four sides are processed with a panel edge groove 10 that matches with the groove 9 in the side plate.

Embodiment 3

[0077] The preparation method of Example 3 is basically the same as that of Example 1, except that:

[0078] In the middle of each side plate 3, a wire groove 11 for threading wires is processed.

[0079] Two adjacent wall panels are spliced by splicing buckles 12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com