Cement ceiling board with electromagnetic shielding function and its semi-dry preparation process

An electromagnetic shielding and preparation process technology, applied in the field of cement ceiling panels and semi-dry preparation processes, can solve the problems of restricting cement-based ceiling panels, high density and compressive strength, low breaking load, etc., and avoid electromagnetic shielding ceilings. Effects of plate delamination, high breaking load, enhanced bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

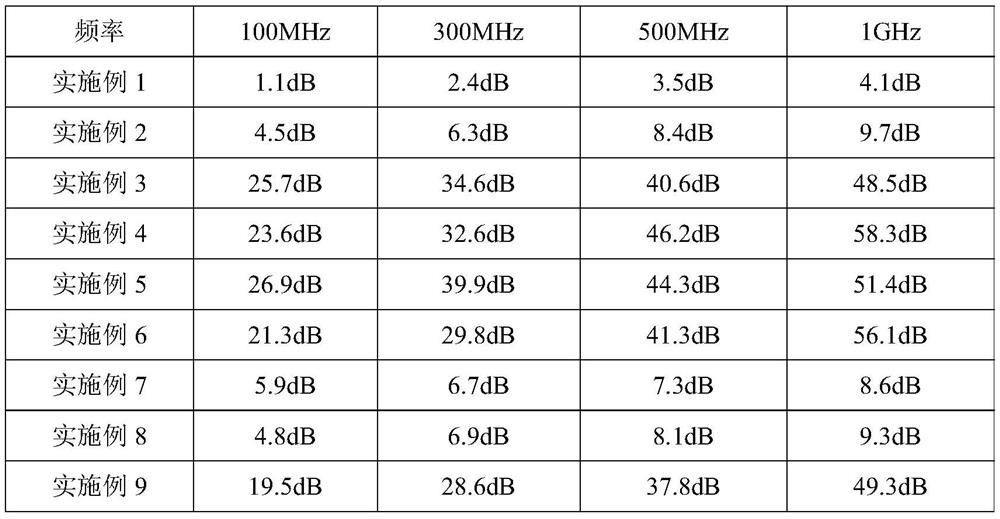

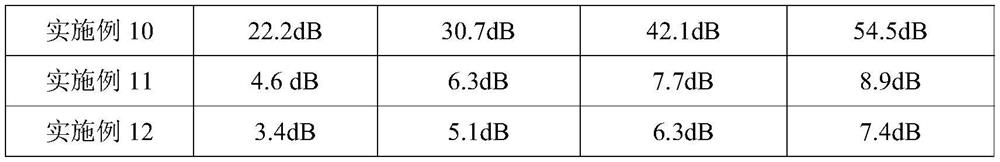

Examples

Embodiment 1

[0051] A cement ceiling board, raw materials include cement, and its preparation process comprises the steps:

[0052] (1) Add the cement into the homogenization tank according to the water-cement ratio of 2.8 and stir to obtain cement slurry;

[0053] (2) Inject the cement slurry obtained in step (1) into the felt mold, pressurize and dehydrate the slurry to form after the injection is completed, the forming pressure is set to 60MPa, and the pressure holding time is 10min to obtain the cement ceiling slab;

[0054] (3) Put the cement slab obtained in step (2) into a steam curing room for steam curing for 12 hours, and set the curing temperature to 50° C. After completion, place the obtained hardened cement slab in a dry environment at 50° C. to dry for 3 hour, that is, a cement ceiling board.

Embodiment 2

[0056] 1. A cement ceiling board, such as figure 1 As shown, it is composed of a cement layer 1 and a carbon fiber mesh cloth 2, wherein the carbon fiber mesh cloth 2 is laid between the cement layers 1 to form an electromagnetic shielding cement ceiling board composed of an upper, middle and lower three-layer structure : The mesh size of the carbon fiber mesh cloth is 5mm×5mm.

[0057] 2. The method for preparing the cement ceiling board described in this embodiment comprises the following steps:

[0058] (1) adding the cement into the homogenization tank according to the water-cement ratio of 3 and stirring to obtain cement slurry;

[0059] (2) Inject the cement slurry obtained in step (1) into the felt mold. When half of the slurry is injected, lay the carbon fiber mesh cloth on the surface of the slurry, and then continue to inject the remaining slurry into the surface of the carbon fiber mesh cloth. Pressurized dehydration molding, the molding pressure is 60MPa, and the...

Embodiment 3

[0062] 1. An electromagnetic shielding cement ceiling board, such as figure 1As shown, it is composed of a cement layer 1 and a carbon fiber mesh cloth 2, and the carbon fiber mesh cloth 2 is laid between the cement layers 1 to form an electromagnetic shielding cement ceiling board composed of an upper, middle and lower three-layer structure.

[0063] Wherein, the mesh size of the carbon fiber mesh cloth is 5mm×5mm. Described cement layer 1 is made by powdery material A and solution B, and described powdery material A is made up of the raw material of following weight portion: cement 55 parts, silica fume 4 parts, fly ash 6 parts, polyvinylpyrrolidone (molecular weight 2.0×10 4 ) 1.0 copies.

[0064] The solution B is composed of the following raw materials in parts by weight: 98 parts of water, 1.6 parts of KH550 silane coupling agent, 0.14 parts of graphene oxide modified by ferric oxide, wherein; the GO~Fe 3 o 4 The loading amount of ferric oxide in the medium is 3.5% (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com