Turbomachine combustion chamber with helical air circulation

A technology of combustion chamber and turbine engine, applied in the field of combustion chamber, to achieve the effect of increasing efficiency, reducing weight and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

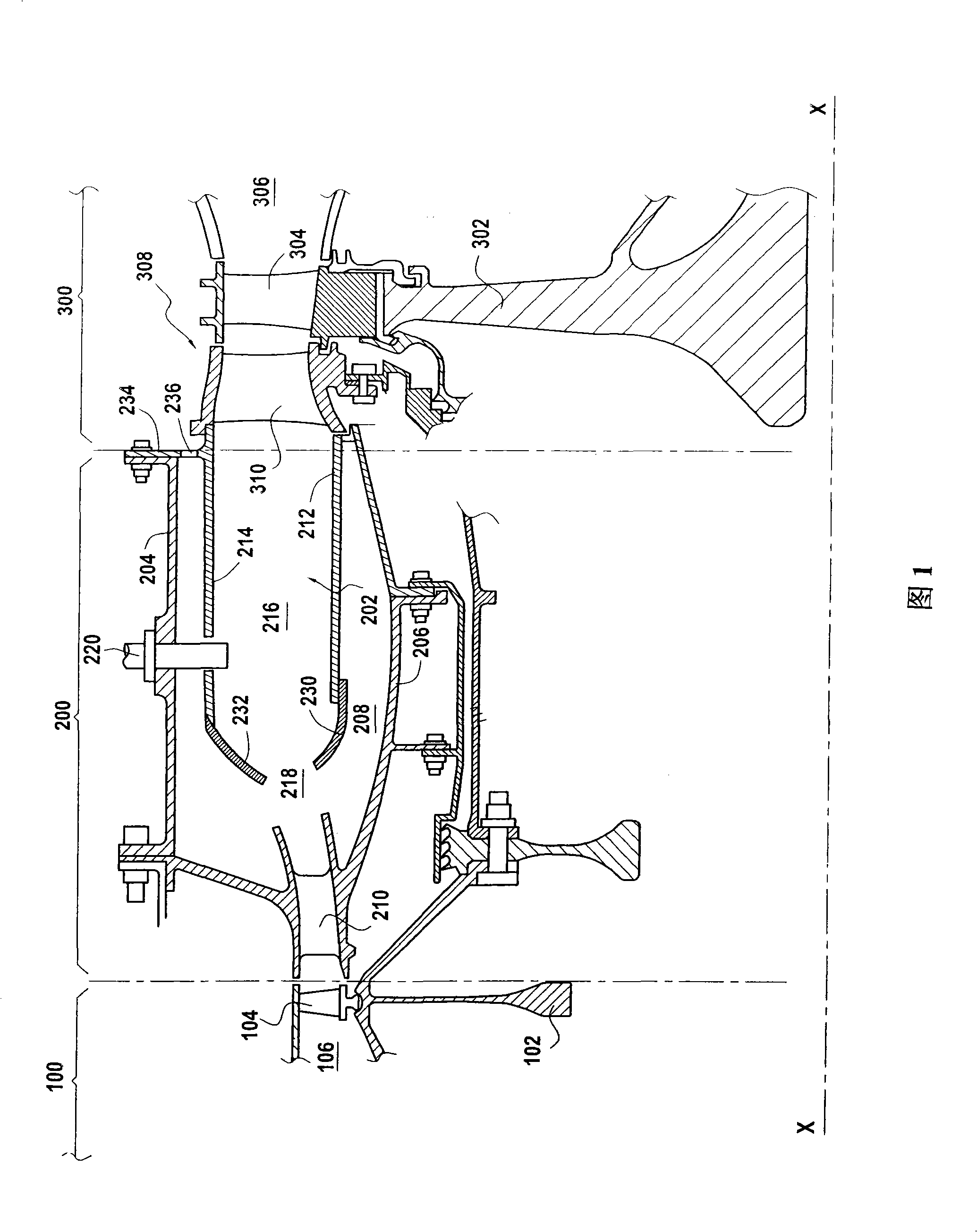

[0029] Figure 1 is a partial schematic view of a turbine, shown along the X-X longitudinal axis. Along the longitudinal axis, the turbine specifically comprises: an annular compression section 100; an annular combustion section 200 arranged at the outlet of the compression section 100 in the direction of air flow through the turbine; and an annular turbine section 300 located at the outlet of the combustion section 200. The air injected into the turbine can thus pass continuously through the compression section 100 , then the combustion section 200 , and finally enter the turbine section 3 .

[0030] The compression section 100 consists of a plurality of rotors 102, each equipped with a blade 104 (Figure 1 shows only the last stage of the compression section). The blades 104 of these stages are arranged in an annular channel 106 through which the turbine air passes, the channel section decreasing gradually from upstream to downstream. In this way, when the air injected into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com