Optical sensor element, optical sensor device and image display device using optical sensor element

A technology for optical sensors and components, applied in electrical components, electrical solid-state devices, semiconductor devices, etc., can solve the problems of lower yield, many manufacturing processes, and difficulty in ensuring the flatness of components, so as to suppress the increase in process steps and maintain switching. characteristics, the effect of low noise characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

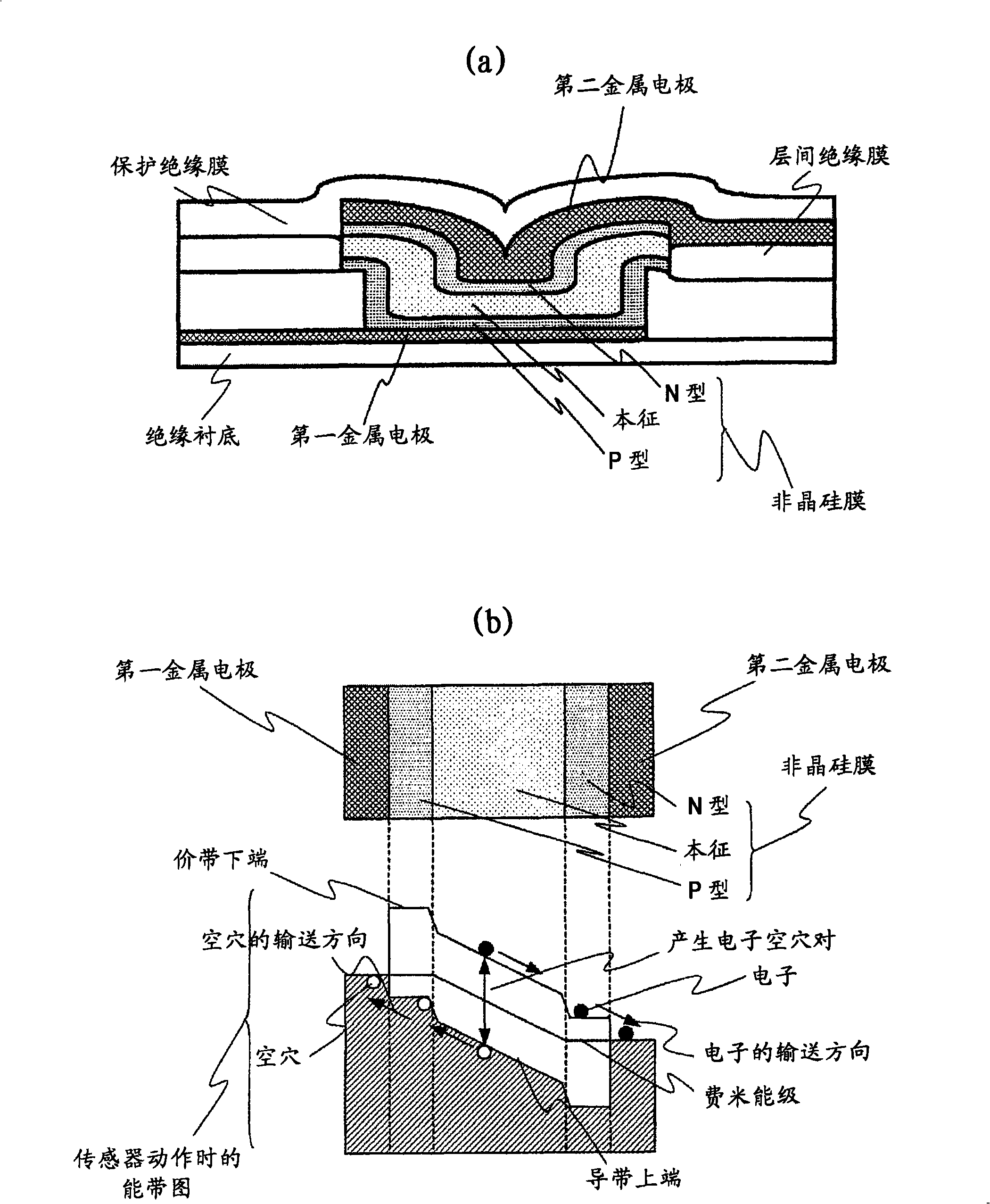

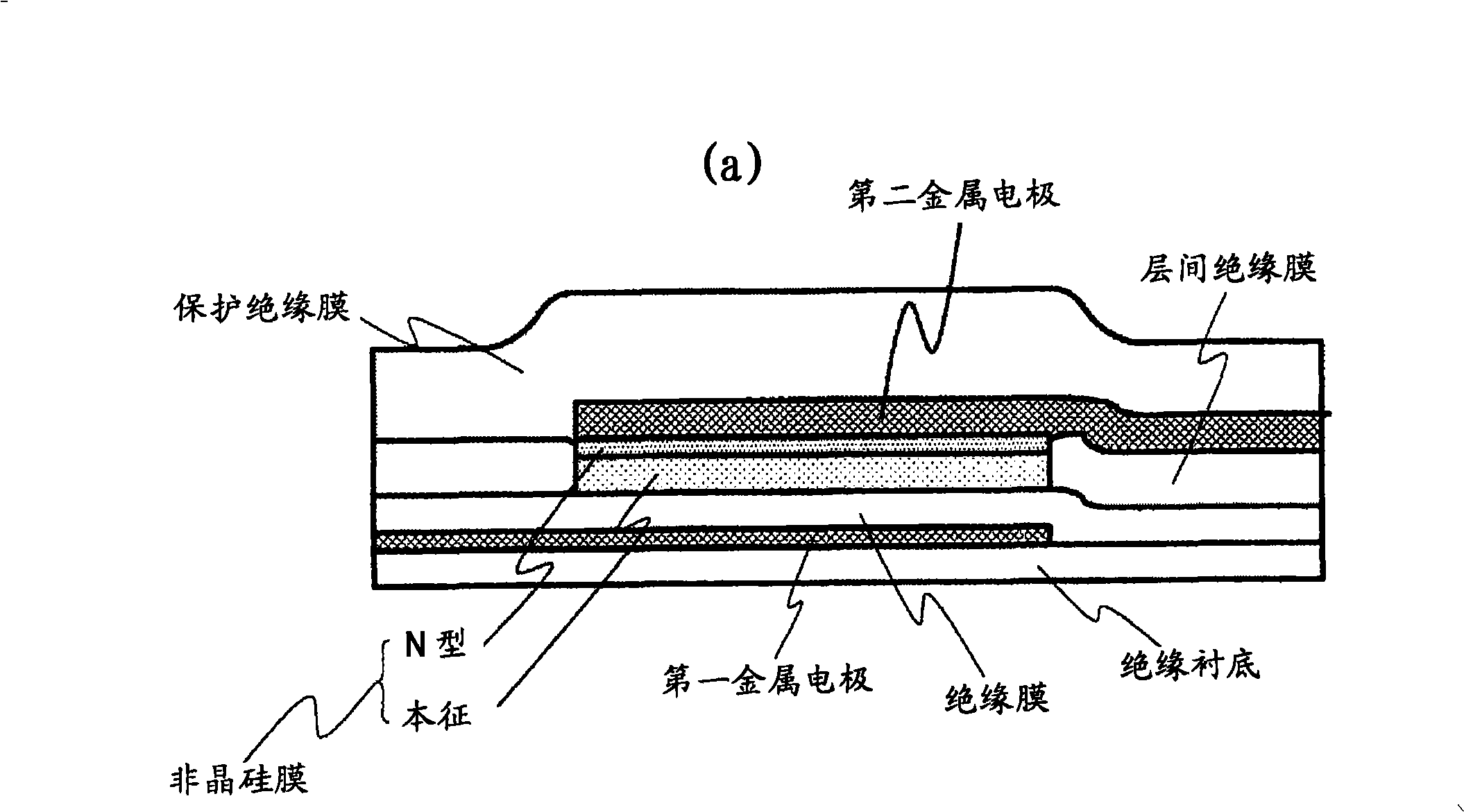

[0108] image 3 is a conceptual diagram of the photosensor element of the present invention. image 3 (a) is a cross-sectional view of an optical sensor element formed on an insulating substrate, image 3 (b) is a plan view.

[0109] exist image 3In this method, a polysilicon film is used to make a first electrode on an insulating substrate, a light-receiving layer is made of an amorphous silicon film thereon, and further, a first electrode transparent to visible light-near-infrared light is made through an insulating layer thereon. Two electrodes (the so-called transparent to visible light-near-infrared light mentioned here means that the energy transmittance for light with a wavelength of 400nm to 1000nm is more than 75%).

[0110] The first electrode is connected to the wiring layer through the contact hole. image 3 The example in fig. shows the case where the wiring layer is made of the same material as that of the second electrode, but it may be of a different mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com