Anti-scatter grid for an x-ray device with non-uniform distance and/or width of the lamellae

An anti-scatter, grid technology used in materials analysis using radiation, radiation/particle processing, using apertures/collimators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

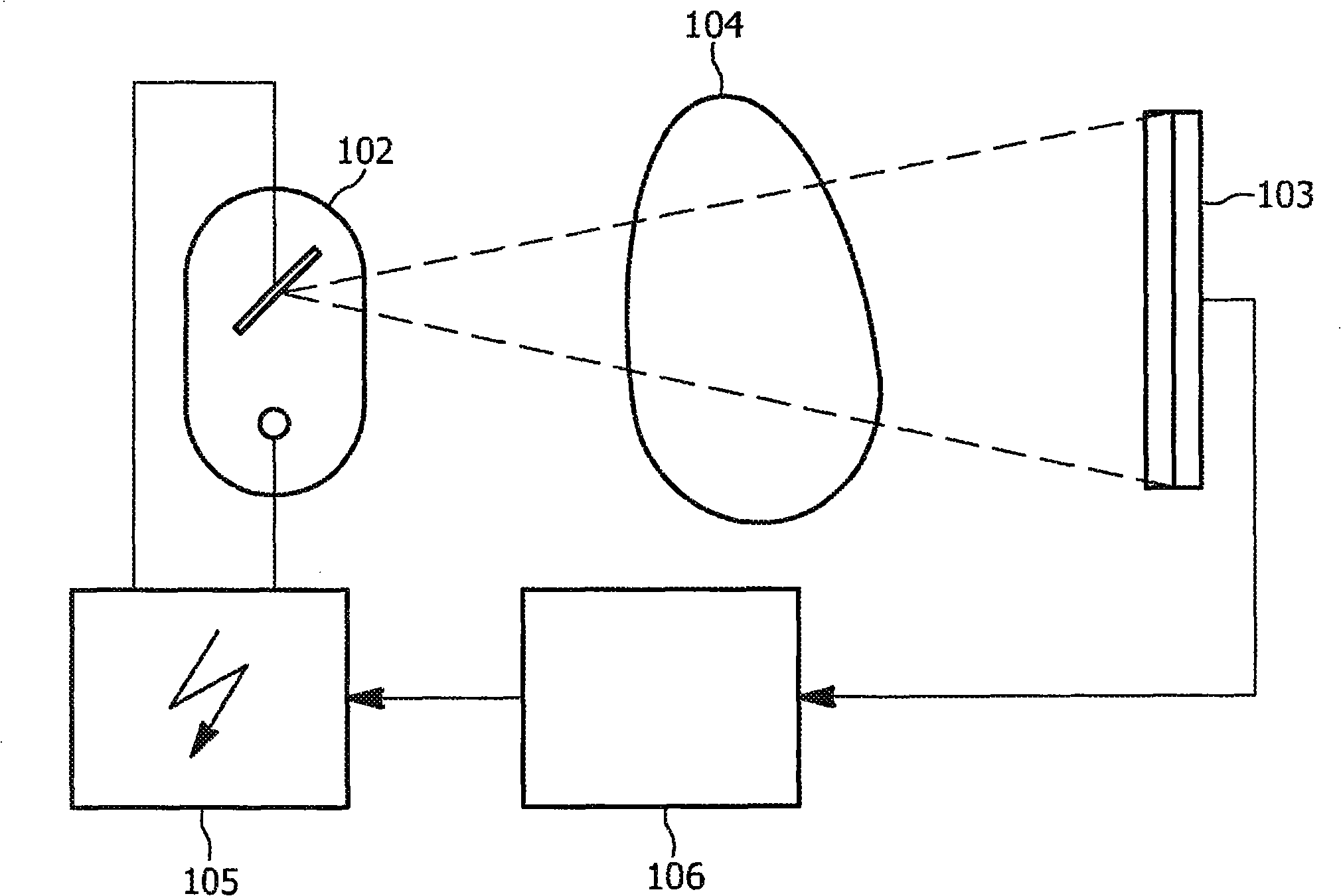

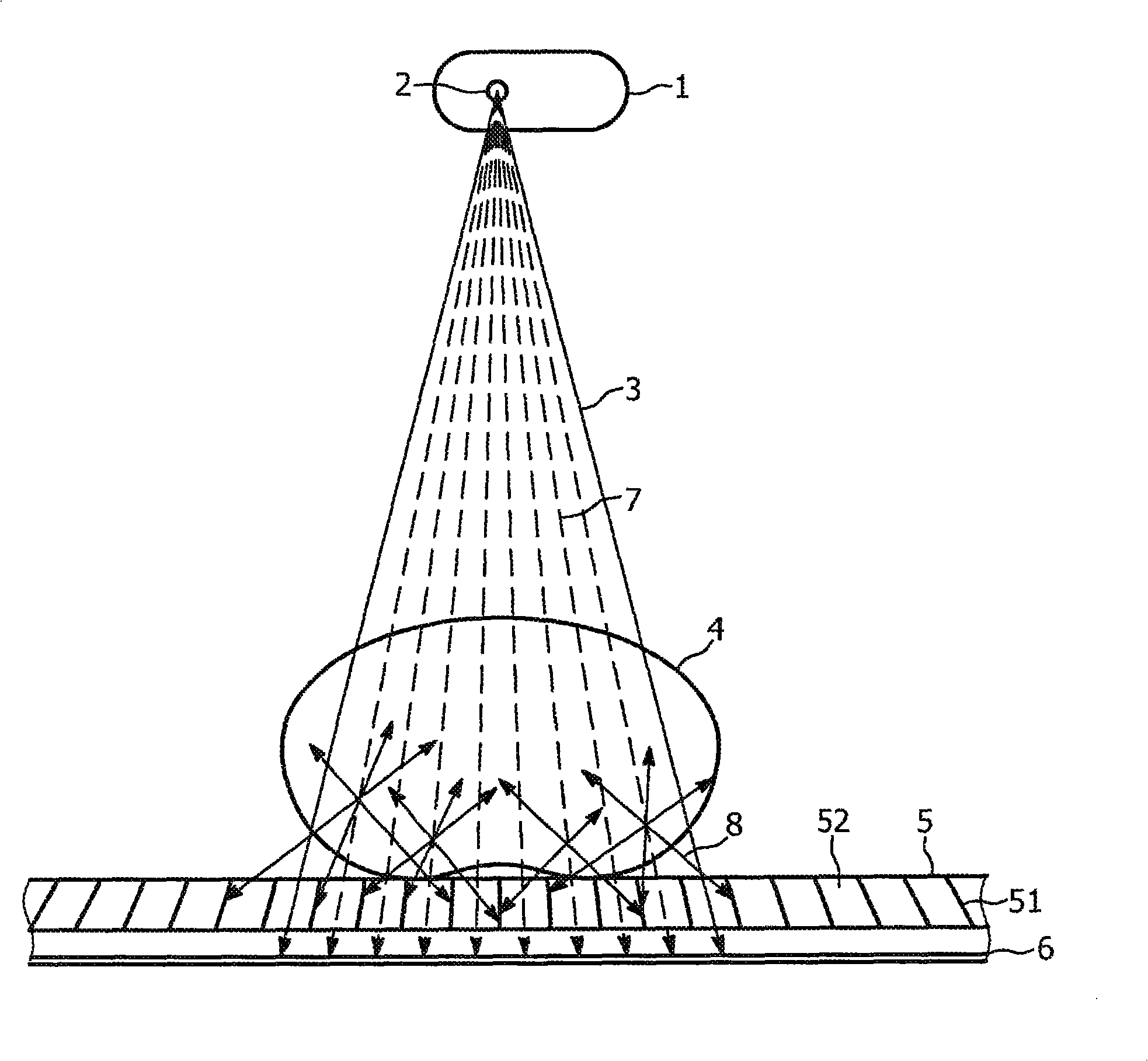

[0019] image 3 is a sketch of an x-ray system with an anti-scatter grid. From a focal point 2 of an X-ray tube 1 an X-ray beam 3 is applied to an object 4 to be examined, eg a patient. The X-rays penetrating the object 4 to be inspected then impinge on the anti-scatter grid 5 and the remaining radiation fraction finally impinges on the X-ray detector 6 . The anti-scatter grid 5 mainly includes: an absorbing layer or flakes 51; and a trench medium or filling material 52 provided between the flakes. The flakes are usually made of lead with a high absorption of X-rays and have a small volume and are oriented towards the grid focus at a distance from the grid 5, which in this case corresponds to the focus 2 . The trenched media 52 often comprises fiber, paper or aluminum and maximizes the transmission of x-rays.

[0020] The anti-scatter grid 5 is mainly used to pass the primary radiation 7 which penetrates the object 4 to be inspected, so that this radiation can impinge on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com