Thrust generator for a propulsion system

A thrust generator, generator technology, applied in the direction of high-efficiency propulsion technology, engine control, power plant type, etc., can solve problems such as engine damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

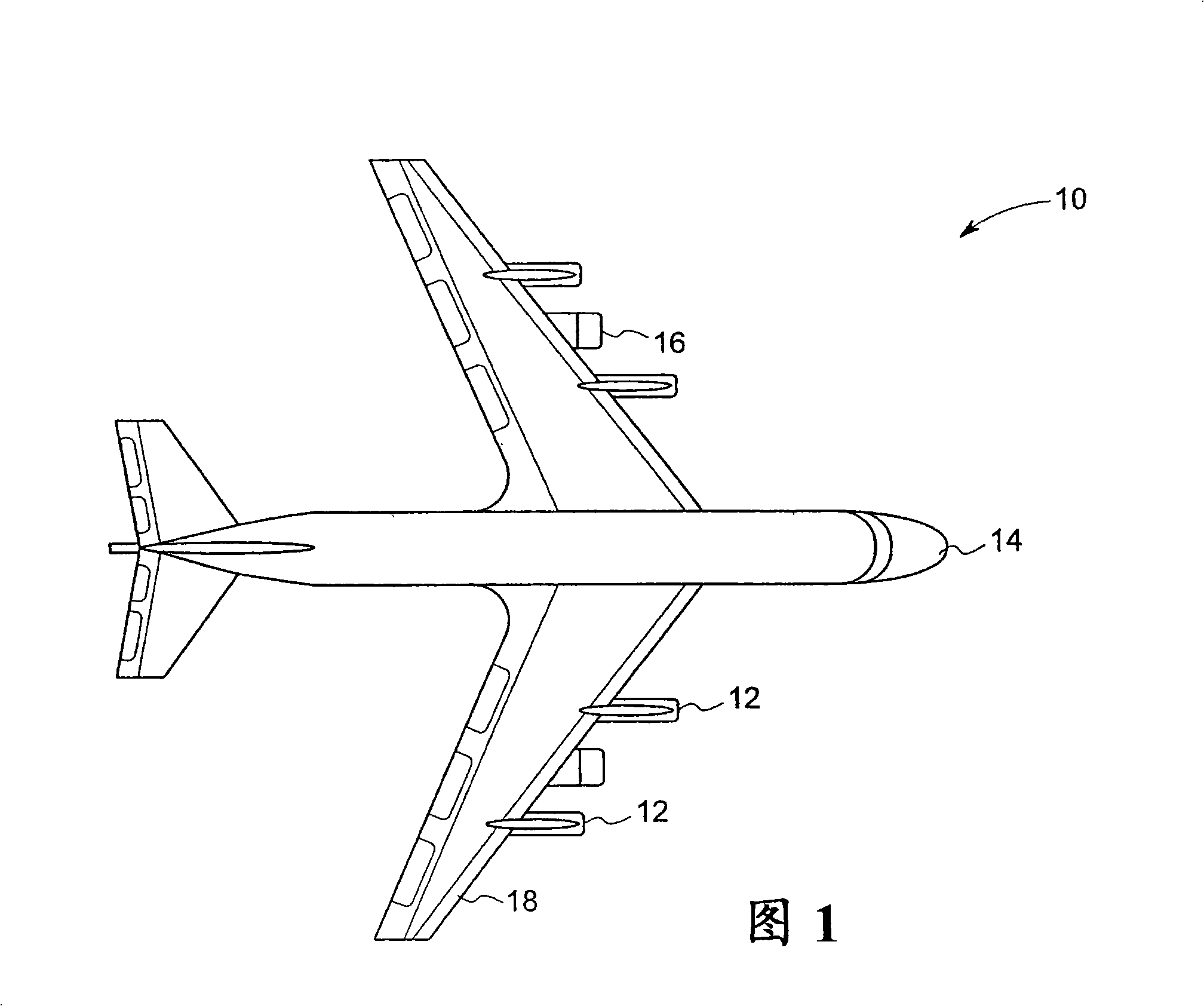

[0072]As discussed in more detail below, embodiments of the present technology function to increase the efficiency of propulsion systems, such as jet aircraft powered by turbojet engines. Specifically, the present technology utilizes a combination of working fluid and ambient air to generate thrust to drive a propulsion system, thereby increasing the efficiency of the system and reducing specific fuel consumption. Turning now to the drawings and referring initially to FIG. 1 , there is shown an aircraft 10 having a plurality of thrust generators, indicated generally at 12 . Aircraft 10 includes an aircraft frame 14 and a gas generator 16 coupled to the aircraft frame 14 . In the exemplary embodiment, gas generator 16 includes a jet engine configured to generate exhaust. As shown, aircraft 10 includes two jet engines 16 located at wings 18 of the aircraft. However, more or fewer gas generators or jet engines 16 may be utilized to power aircraft 10 and generate exhaust.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com