Sand prevention clamp sand spraying device and its use method

A sandblaster and sand control technology, which is applied in earth-moving drilling, fluid production, wellbore/well components, etc., can solve the problems of large lifting load, stuck and unable to lift out, etc., and achieves the effect of increasing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

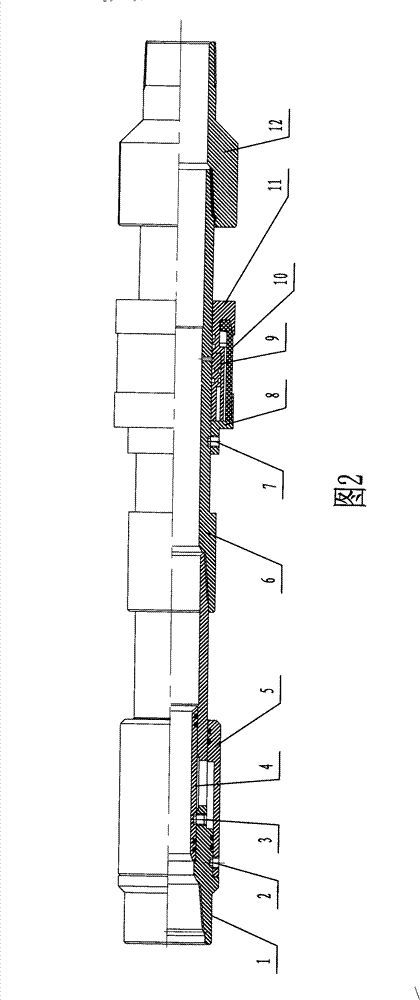

[0024] In order to better understand the shape, structure and features of the present invention, the present invention will be described in detail below through preferred embodiments and with reference to the accompanying drawings. In order to make the structure of the present invention clearer, the actual scale relationship of the drawings may be changed during the drawing process, which should not be construed as a limitation to the patent application.

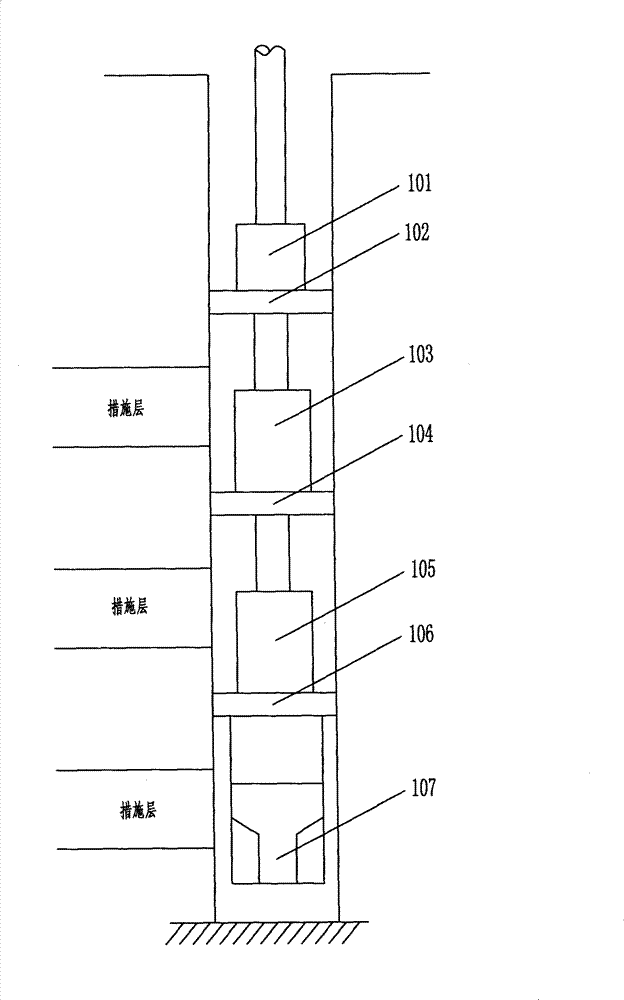

[0025] like figure 1 As shown, it is a preferred embodiment of a multi-layer layered fracturing string for sand control, and the string includes a hydraulic anchor 101, an upper packer 102, an upper sand control sand blasting string connected in sequence from top to bottom. 103, intermediate packer 104, lower sand jam prevention sand blaster 105, lower packer 106 and setting ball seat 107.

[0026] The hydraulic anchor 101 is used to overcome the upward force generated by the pipe string under the pressure and keep the pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com