Pressure type pump reducing pulsation for vehicle slip control system

A slip control, pressure-type technology, applied in the field of pressure-type pumps, can solve problems such as impact and failure, and achieve the effect of reducing machining time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

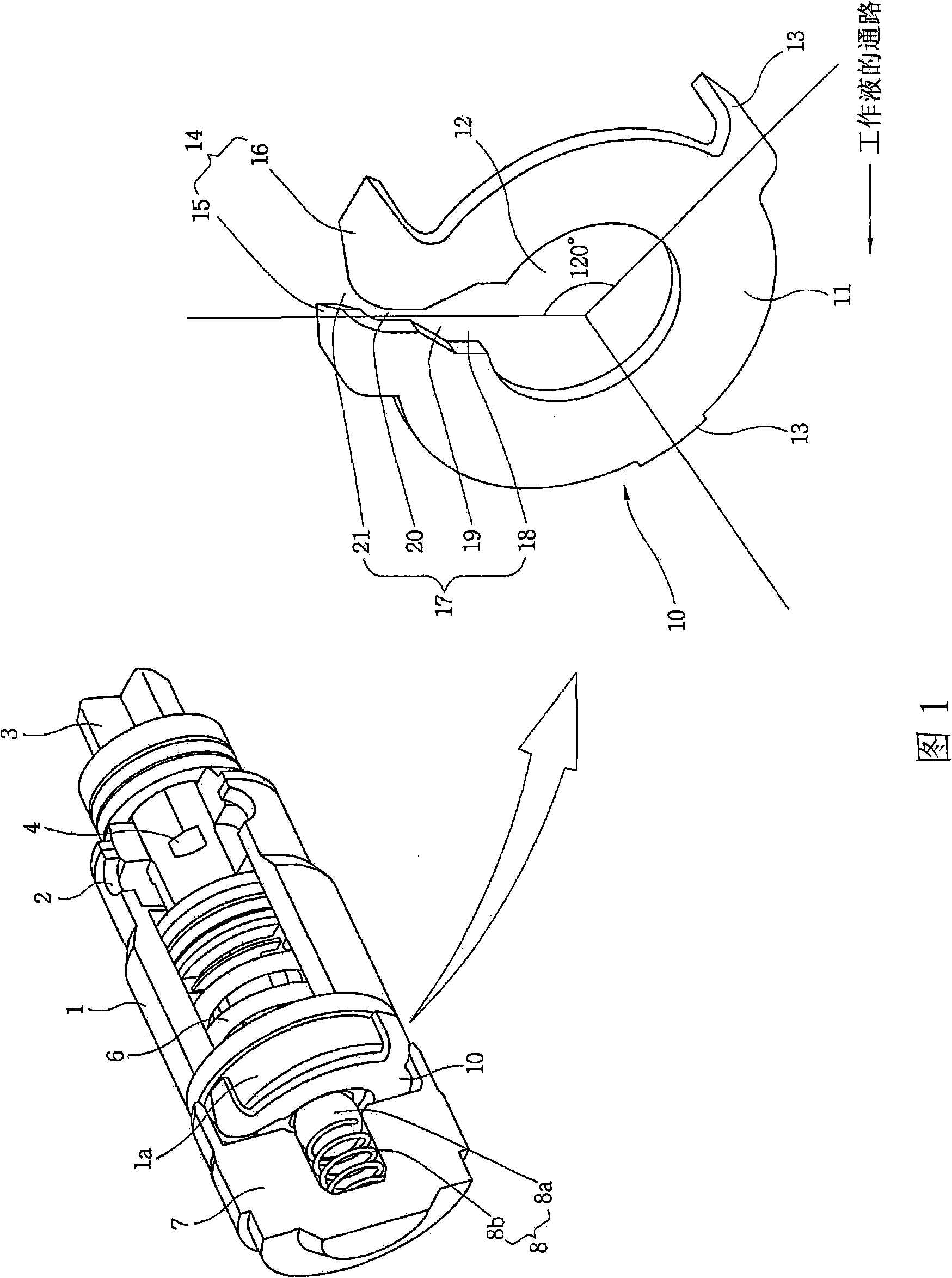

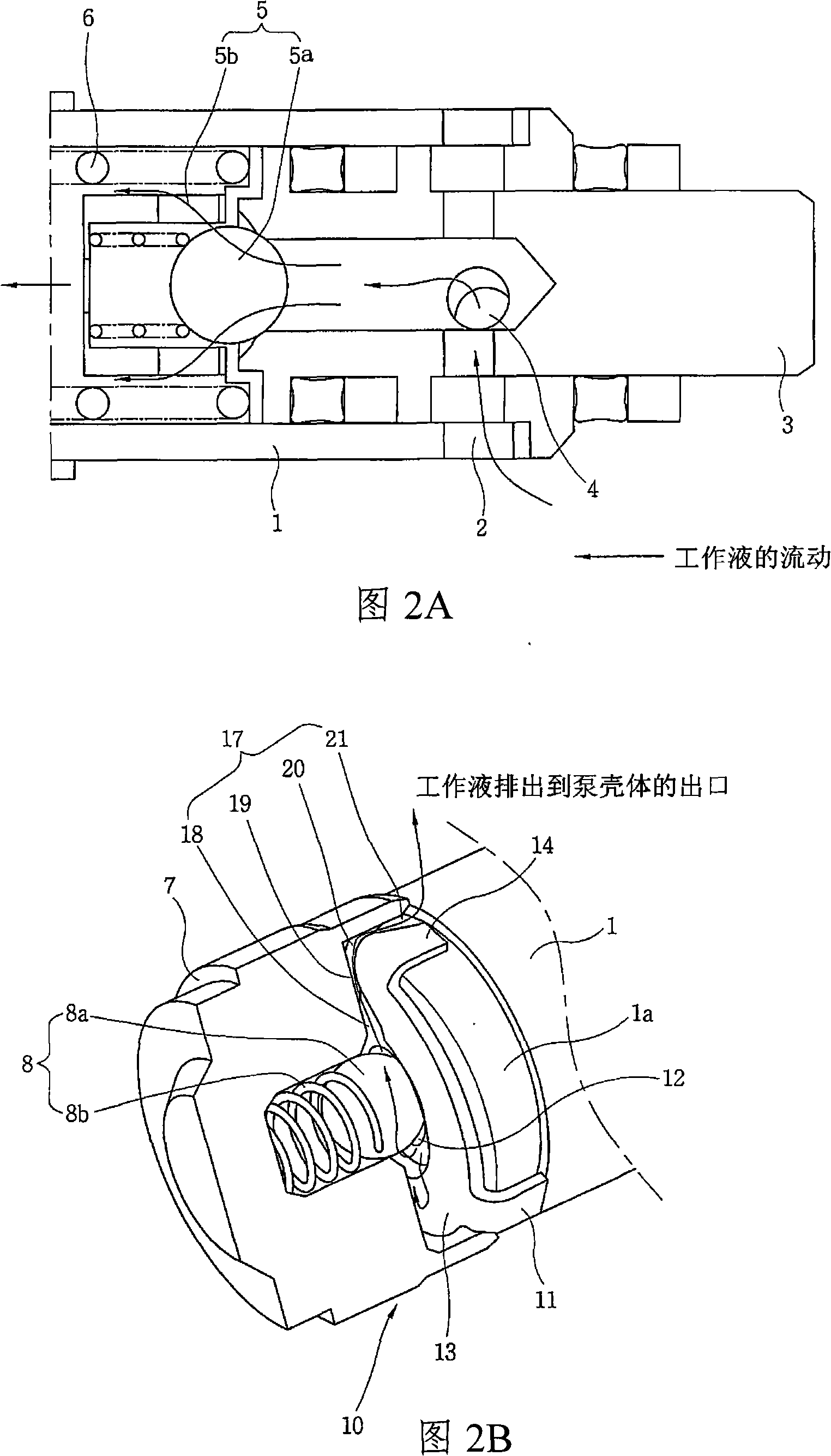

[0023] FIG. 1 is a schematic structural view of an embodiment of a pressure-type pump with reduced pulsation used in a vehicle slip control system according to the present invention. According to an oil control pump of an electronically controlled braking system of the present invention, oil as a working fluid is injected and circulated in the pump, and the pump includes: a bushing 1, a plunger 3, a check valve inlet 5, a check valve Valve outlet 8 and orifice 10. The bushing 1 is fixed on the pump casing and forms a working fluid passage inside it. The plunger 3 is elastically supported by the inner spring 6 in the bushing 1, and allows the working fluid to flow into the pump when the pump is working. The one-way valve inlet 5 is arranged at the front end of the plunger 3 so as to discharge the working fluid into the bushing 1 under the pressure of the working fluid flowing into the plunger 3 . The check valve outlet 8 is accommodated in the cap 7 which is fixed at one end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com