Drive seat structure of bicycle hub

A driving seat and bicycle technology, which is applied in the structural field of parts, can solve the problems of high performance requirements that do not meet lightweight, cut or damage of aluminum sprockets, and heavy weight, so as to reduce maintenance costs, reduce wear, increase The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

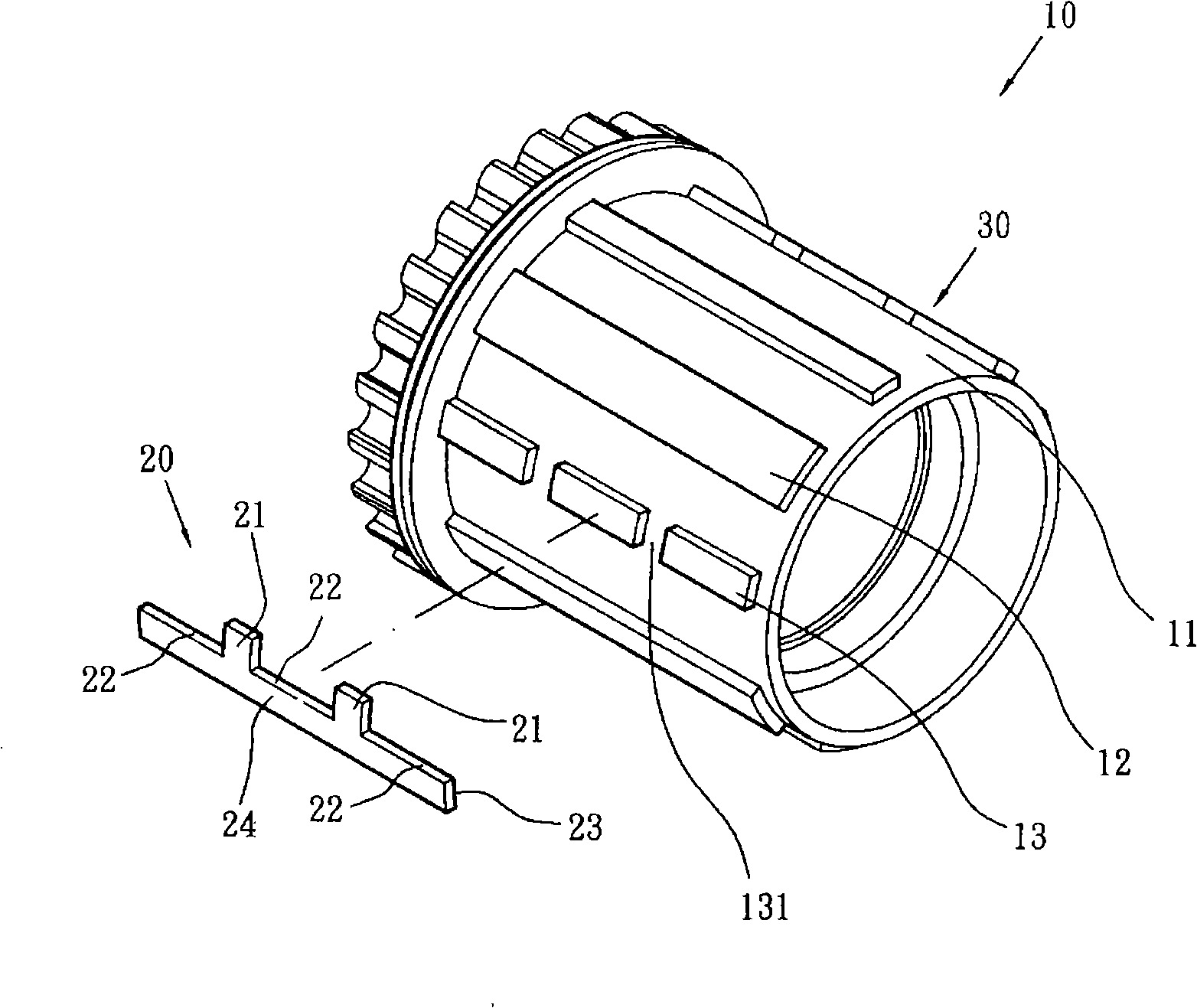

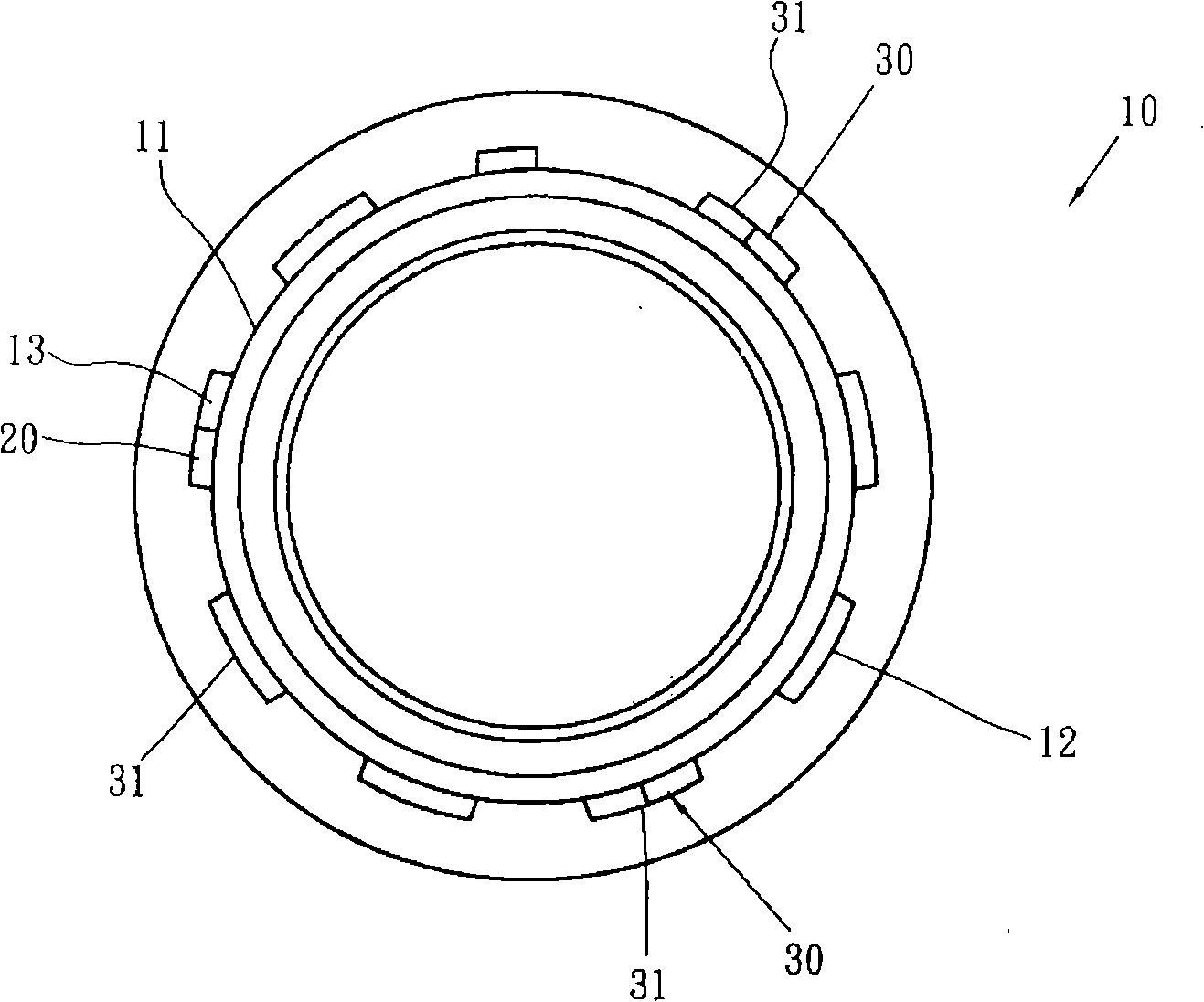

[0023] First please refer to figure 1 Referring to Fig. 5, the driving seat structure of a bicycle hub provided by the present invention is mainly arranged on one side of the hub 40, which includes: a driving seat 10, and the driving seat 10 A plug-in 20.

[0024] The drive seat 10 is an aluminum alloy in a stepped ring, which has a transmission part 11 with a smaller outer diameter. The outer diameter edge ring of the transmission part 11 is provided with six transmission bars 12 and three intermittent protrusions. Strips 13 are respectively axially extended by the drive seat 10 to a preset length, wherein each of the intermittent convex strips 13 is in the shape of a discontinuous flange with two grooves 131; the intermittent convex strips The two side edges of the groove 131 formed by 13 are dovetail-shaped recesses.

[0025] The insert 20 is a steel material that is embedded and attached to each of the intermittent protrusions 13, and the intermittent protrusions 13 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com